This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

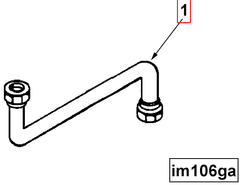

The Cummins 3069088 Manifold Pressure Tube is a critical component in heavy-duty truck engines, designed to enhance engine performance and efficiency. Understanding its function and significance is essential for maintaining and optimizing truck operations.

Basic Concepts of Manifold Pressure Tubes

A Manifold Pressure Tube measures the pressure within the intake manifold of an engine. It provides data that helps regulate fuel injection and air intake, ensuring the engine operates within optimal parameters. This component is integral to maintaining engine performance by allowing the engine control unit to make adjustments based on the pressure readings it provides 1.

Purpose and Function

The Cummins 3069088 Manifold Pressure Tube is engineered to monitor and transmit manifold pressure data to the engine’s control system. This information is vital for the engine control unit to adjust fuel delivery and air intake in real-time, enhancing engine efficiency and performance. By ensuring that the engine operates under the most favorable conditions, this component contributes to smoother operation and potentially extends the engine’s lifespan 2.

Key Features

This Cummins part is characterized by its robust design and high-quality materials, which are selected to withstand the demanding conditions of heavy-duty truck engines. Its construction includes precision-engineered components that ensure accurate pressure readings. Additionally, the tube is designed to be durable and resistant to the high temperatures and pressures found within engine compartments.

Benefits

The advantages of the 3069088 Manifold Pressure Tube include improved engine performance through precise pressure monitoring, enhanced reliability due to its robust construction, and increased durability that ensures long-term operation under harsh conditions. These benefits contribute to overall vehicle efficiency and can lead to better fuel economy and reduced emissions 3.

Installation and Compatibility

Proper installation of this part is crucial for ensuring it functions correctly within the engine system. Installation procedures should follow manufacturer guidelines to ensure compatibility and optimal performance. It is important to verify that the tube is compatible with the specific truck model to avoid any issues with engine operation.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3069088 Manifold Pressure Tube involves regular inspection for signs of wear or damage. Common issues may include leaks or inaccurate pressure readings, which can often be addressed through simple repairs or adjustments. Troubleshooting should be conducted according to manufacturer recommendations to ensure the component continues to operate effectively.

Performance Impact

The Cummins 3069088 Manifold Pressure Tube plays a role in enhancing engine performance by providing accurate pressure data that allows for precise fuel and air management. This can lead to improvements in fuel efficiency and reductions in emissions, contributing to more environmentally friendly truck operations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a strong reputation in the automotive industry, Cummins is committed to innovation and quality in the manufacturing of automotive components. The company’s dedication to excellence is reflected in its products, including the Cummins 3069088 Manifold Pressure Tube, which is designed to meet the rigorous demands of heavy-duty truck engines.

Role of the Manifold Pressure Tube in Engine Systems

The manifold pressure tube, identified by part number 3069088, is an essential component in the engine system, facilitating the measurement and regulation of manifold pressure. This component is integral to several key engine functions and interacts with various other components to ensure optimal engine performance.

Interaction with the Manifold Absolute Pressure (MAP) Sensor

The manifold pressure tube is directly connected to the MAP sensor. The MAP sensor measures the pressure inside the intake manifold, which is vital for the Engine Control Unit (ECU) to calculate the correct air-fuel mixture. Accurate readings from the MAP sensor, facilitated by the manifold pressure tube, allow the ECU to make precise adjustments to fuel injection and ignition timing.

Connection to the Throttle Body

The manifold pressure tube is often routed to the throttle body, where it monitors the pressure changes as the throttle plate opens and closes. This data is crucial for the ECU to adjust the air intake in real-time, ensuring that the engine operates efficiently under varying load conditions.

Integration with the Intake Manifold

Within the intake manifold, the manifold pressure tube plays a role in distributing the measured pressure data. This information helps in the uniform distribution of air across all cylinders, promoting balanced combustion and reducing the likelihood of misfires.

Role in Turbocharged and Supercharged Engines

In turbocharged and supercharged engines, the manifold pressure tube is particularly important. It helps in monitoring the boost pressure, allowing the ECU to control the wastegate or bypass valve. This regulation ensures that the engine receives the optimal amount of pressurized air, enhancing performance while preventing over-boosting, which can lead to engine damage.

Contribution to Emission Control Systems

The data from the manifold pressure tube also feeds into the emission control systems. By providing accurate pressure readings, it assists in the proper functioning of components like the Exhaust Gas Recirculation (EGR) valve and the Oxygen (O2) sensors. This integration helps in reducing harmful emissions and ensuring the engine meets environmental regulations.

Support for Diagnostic Systems

Finally, the manifold pressure tube supports the engine’s diagnostic systems. It provides continuous pressure data that can be monitored for anomalies, aiding in the early detection of potential issues such as vacuum leaks or malfunctioning sensors. This proactive monitoring is key to maintaining engine health and performance.

Conclusion

The Cummins 3069088 Manifold Pressure Tube is a vital component in heavy-duty truck engines, contributing to engine performance, efficiency, and emissions control. Its robust design, precise pressure monitoring capabilities, and integration with various engine systems make it an essential part of modern engine technology. Proper installation, maintenance, and understanding of its role in engine systems are crucial for maximizing its benefits and ensuring optimal engine operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.