This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

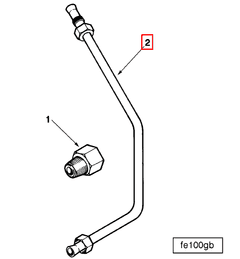

The Manifold Pressure Tube, identified by part number 3071162, is a component manufactured by Cummins, a leader in the automotive and heavy-duty truck industry. This tube plays a role in the engine’s performance and efficiency by facilitating the measurement and regulation of manifold pressure. Understanding its function and significance is vital for maintaining optimal engine operation in heavy-duty trucks.

Basic Concepts and Functionality

Manifold pressure refers to the absolute pressure within the intake manifold of an engine. This pressure is a parameter that influences engine performance and fuel efficiency. The Manifold Pressure Tube is designed to measure and regulate this pressure, ensuring that the engine operates within its optimal range. By maintaining the correct manifold pressure, the engine can achieve better combustion efficiency, leading to improved performance and fuel economy 1.

Purpose and Role in Truck Operation

In the context of heavy-duty truck engines, the Manifold Pressure Tube serves a pivotal function. It ensures that the engine receives the correct air-fuel mixture by monitoring and adjusting the manifold pressure. This regulation contributes to consistent engine performance, enhanced fuel efficiency, and reliable operation. The tube’s accurate measurement capabilities help the engine control unit (ECU) make precise adjustments, which are for the engine’s overall efficiency and durability 2.

Key Features

The Cummins Manifold Pressure Tube is engineered with several key features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring long-lasting operation in demanding environments. The design of the tube includes precise calibration to provide accurate pressure readings, which is vital for the ECU to make informed adjustments. Additionally, the tube is built to withstand the high temperatures and pressures typical of heavy-duty truck engines, ensuring reliable performance under various operating conditions 3.

Benefits

Using the Cummins Manifold Pressure Tube offers several benefits. Improved engine performance is one of the primary advantages, as the tube ensures that the engine operates with the optimal air-fuel mixture. This leads to enhanced fuel efficiency, reducing operating costs for truck operators and fleet managers. The tube’s durable construction and precise calibration also contribute to increased reliability, minimizing the need for frequent replacements or repairs. These benefits translate to improved overall efficiency and cost-effectiveness for heavy-duty truck operations.

Troubleshooting and Maintenance

Common issues with the Manifold Pressure Tube may include inaccurate pressure readings or physical damage to the tube. Troubleshooting steps involve checking the tube for any signs of wear or corrosion and ensuring that it is properly connected to the engine’s intake manifold. Routine maintenance practices include regular inspection of the tube and its connections, cleaning any debris that may affect its performance, and calibrating the tube as necessary to maintain accurate pressure readings. These practices help ensure the optimal performance and longevity of the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and customer satisfaction. The company offers a wide range of products for various industries, including automotive, heavy-duty trucking, and power generation. Cummins’ commitment to advancing technology and delivering reliable, high-performance products has made it a trusted name in the industry.

Manifold Pressure Tube (Part 3071162) in Cummins Engines

The Manifold Pressure Tube (Part 3071162) is a component in Cummins engines, facilitating the measurement of manifold pressure. This part is integral to the engine’s performance and efficiency, ensuring accurate readings that are essential for optimal operation.

N14 MECHANICAL

In the N14 MECHANICAL engine, the Manifold Pressure Tube (Part 3071162) is designed to connect the intake manifold to the turbocharger’s wastegate. This connection allows for precise monitoring of the intake manifold pressure, which is crucial for maintaining the turbocharger’s boost pressure and overall engine performance. The tube’s design ensures minimal pressure loss, contributing to the engine’s efficiency and reliability.

Role of Part 3071162 Manifold Pressure Tube in Engine Systems

The Manifold Pressure Tube (part 3071162) is a component in the orchestration of an engine’s performance, specifically within the realms of plumbing and air-fuel control systems.

In the plumbing aspect of engine systems, the Manifold Pressure Tube serves as a conduit that facilitates the transfer of pressure readings from the intake manifold to various engine control units (ECUs) or gauges. This tube is integral in maintaining the integrity of the pressure signal, ensuring that it is accurately conveyed without loss or distortion. Its placement within the engine bay is meticulously planned to avoid interference with other components while withstanding the harsh environment of fluctuating temperatures and vibrations.

Regarding air-fuel control, the Manifold Pressure Tube plays a significant role in the feedback loop that governs the air-fuel mixture. By providing real-time data on manifold pressure to the ECU, it allows for precise adjustments to be made to the fuel injection timing and quantity. This ensures that the engine operates efficiently under varying conditions, from idle to full throttle. The tube’s connection to the intake manifold means it directly influences the data used to calculate the optimal air-fuel ratio, contributing to the engine’s overall performance, fuel efficiency, and emissions output.

Conclusion

In summary, the Manifold Pressure Tube (part 3071162) is a linchpin in the engine’s plumbing and air-fuel control systems, ensuring that pressure data is accurately transmitted and utilized for optimal engine operation.

-

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Mananathan, R. Automobile Wheel Alignment and Wheel Balancing. SAE International, 2022.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.