This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

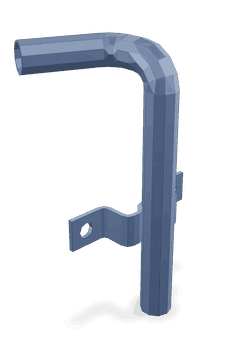

The Cummins 3092000 Breather Tube is a component designed to facilitate the efficient operation of heavy-duty trucks. Its purpose is to manage the pressure within the engine compartment, ensuring optimal performance and longevity of the engine. This part is integral to maintaining the engine’s efficiency by allowing for the equalization of pressure and preventing contamination 1.

Basic Concepts of Breather Tubes

A breather tube is a component found in a truck’s engine system that allows for the release of pressure and the exchange of air within the engine compartment. It operates by providing a pathway for air to enter and exit the engine, which helps in maintaining a stable environment inside the engine. This stability is crucial for the engine’s efficiency and longevity, as it prevents the buildup of pressure that could lead to damage or reduced performance 2.

Purpose of the Cummins 3092000 Breather Tube

The Cummins 3092000 Breather Tube plays a specific role in the operation of a truck by facilitating pressure equalization and contamination prevention within the engine compartment. It allows for the release of excess pressure that builds up during engine operation, which helps in maintaining a consistent environment inside the engine. Additionally, it prevents contaminants from entering the engine, which could otherwise lead to wear and tear on engine components 3.

Key Features

The Cummins 3092000 Breather Tube is characterized by several key features that enhance its performance and durability. It is composed of materials that are resistant to the harsh conditions within an engine compartment, ensuring longevity. The design of the tube includes elements that facilitate easy installation and maintenance. Additionally, it may have unique attributes such as filters or valves that further enhance its functionality.

Benefits

Using the Cummins 3092000 Breather Tube is associated with several benefits. It contributes to improved engine performance by maintaining a stable environment within the engine compartment. This stability leads to reduced maintenance requirements, as the engine is less likely to suffer from issues related to pressure buildup or contamination. Furthermore, the breather tube enhances the longevity of engine components by preventing damage that could be caused by these factors.

Installation Process

The installation of the Cummins 3092000 Breather Tube should be carried out with attention to detail to ensure optimal performance and safety. The process involves several steps, including the preparation of the installation site, the connection of the tube to the engine, and the securing of all connections. It is important to use the necessary tools and follow best practices to ensure that the tube is installed correctly.

Troubleshooting Common Issues

Common problems that may arise with breather tubes include blockages or leaks. These issues can be diagnosed through visual inspection and testing of the tube’s functionality. To resolve these problems, it may be necessary to clean the tube, replace damaged components, or adjust the installation to ensure proper fit and function.

Maintenance Tips

To keep the Cummins 3092000 Breather Tube in optimal condition, it is important to follow routine maintenance practices. This includes regular inspection of the tube for signs of wear or damage, cleaning to remove any contaminants, and replacement of the tube according to manufacturer guidelines or when signs of failure are detected.

About Cummins

Cummins Inc. is a company with a long-standing reputation in the automotive industry for manufacturing high-quality engine components. Founded with a commitment to innovation and excellence, Cummins has established itself as a leader in the production of reliable and efficient engine parts. The company’s dedication to quality is evident in its products, including the Cummins 3092000 Breather Tube, which is designed to meet the demanding requirements of heavy-duty truck engines.

Cummins Breather Tube 3092000 Compatibility

The Cummins Breather Tube part number 3092000 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is crucial for maintaining the integrity of the engine’s crankcase ventilation system, preventing the buildup of harmful gases and moisture.

QST30 CM552 Engines

The Cummins Breather Tube 3092000 is compatible with the QST30 CM552 engines. This part ensures that the crankcase ventilation system functions correctly, which is essential for the longevity and efficiency of these engines. The breather tube helps in expelling gases from the crankcase, preventing pressure buildup and ensuring that the engine operates smoothly.

Grouping of Compatible Engines

While the specific compatibility of the Cummins Breather Tube 3092000 with the QST30 CM552 engines is well-documented, it is also worth noting that this part is designed to fit a broader range of Cummins engines. The breather tube’s universal design allows it to be used across various engine models, provided they share similar ventilation system requirements. This makes it a versatile component for maintaining engine health across different applications.

Role of Part 3092000 Breather Tube in Engine Systems

The part 3092000 Breather Tube is an essential component in maintaining the health and efficiency of engine systems by facilitating the breather and crankcase ventilation processes.

In the breather system, the 3092000 Breather Tube allows for the release of pressure that builds up within the engine’s crankcase. As the engine operates, it produces gases and vapors that need to be vented to prevent excessive pressure, which could lead to leaks or damage to seals and gaskets. The breather tube directs these gases away from the crankcase, typically routing them back into the intake system where they can be burned in the combustion process, thus reducing emissions and improving engine performance.

Within the crankcase ventilation system, the 3092000 Breather Tube plays a significant role in managing the environment inside the crankcase. It helps in expelling contaminants such as moisture and sludge that can accumulate, ensuring that the crankcase remains clean and free from build-up. This is vital for the longevity of the engine, as a clean crankcase reduces the risk of corrosion and wear on moving parts.

Moreover, the breather tube contributes to the overall pressure balance within the engine. By allowing controlled venting, it helps in stabilizing the pressure differentials that occur during engine operation. This balance is important for the proper functioning of the piston rings and cylinder walls, which rely on consistent pressure to maintain an effective seal and ensure efficient combustion.

In summary, the 3092000 Breather Tube is integral to the breather and crankcase ventilation systems, ensuring that the engine operates within optimal conditions by managing pressure, expelling contaminants, and contributing to a balanced internal environment.

Conclusion

The Cummins 3092000 Breather Tube is a critical component for maintaining the efficiency and longevity of heavy-duty truck engines. By facilitating pressure equalization and preventing contamination, this part ensures a stable environment within the engine compartment. Its robust design and compatibility with a range of Cummins engines make it a versatile and essential component for engine health.

-

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001

↩ -

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.