This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Manifold Pressure Tube 3165345, manufactured by Cummins, is a component designed to enhance the operation of heavy-duty trucks. Cummins, a reputable manufacturer in the automotive industry, is known for producing high-quality components that contribute to the efficiency and reliability of truck engines. This part is integral to the engine system, playing a significant role in maintaining optimal performance.

Basic Concepts of Manifold Pressure Tubes

A Manifold Pressure Tube is a component within the engine system that measures the pressure of the air-fuel mixture entering the engine’s cylinders. This measurement is essential for the engine control unit (ECU) to adjust fuel delivery and ignition timing, ensuring efficient combustion. By providing accurate pressure readings, the Manifold Pressure Tube contributes to the overall performance and fuel efficiency of the truck 1.

Role of the 3165345 Manifold Pressure Tube in Truck Operation

The 3165345 Manifold Pressure Tube specifically plays a role in the engine system by accurately measuring manifold pressure. This data allows the ECU to make precise adjustments to fuel injection and ignition timing, which are vital for optimal engine performance. The tube interacts with various engine components, including the intake manifold and the ECU, to ensure that the engine operates within its designed parameters, enhancing both power output and fuel efficiency.

Key Features of the 3165345 Manifold Pressure Tube

The 3165345 Manifold Pressure Tube is designed with several features that enhance its functionality and durability. Constructed from high-quality materials, it ensures resistance to corrosion and wear, which are common issues in the harsh environment of a truck engine. The build quality of the tube is robust, allowing it to withstand the high pressures and temperatures within the engine system. Additionally, its precise engineering ensures accurate pressure readings, which are critical for the ECU to make the necessary adjustments for optimal engine performance 2.

Benefits of Using the 3165345 Manifold Pressure Tube

Utilizing the 3165345 Manifold Pressure Tube offers several advantages. It contributes to improved engine efficiency by providing accurate pressure readings that allow the ECU to optimize fuel delivery and ignition timing. This results in better fuel economy and reduced emissions. The tube’s durable construction ensures reliability, minimizing the need for frequent replacements. Furthermore, its precise measurements enhance overall engine performance, leading to smoother operation and increased power output.

Installation and Integration

Proper installation of the 3165345 Manifold Pressure Tube is crucial for its effective operation. It is designed to be compatible with various Cummins engine models, ensuring seamless integration with existing engine components. During installation, it is important to follow manufacturer guidelines to ensure that the tube is correctly positioned and securely fastened. This will help maintain the accuracy of pressure readings and ensure the tube functions as intended within the engine system.

Maintenance and Troubleshooting

Regular maintenance of the 3165345 Manifold Pressure Tube is important to ensure its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, such as cracks or corrosion. Cleaning the tube and its connections can prevent buildup that might affect pressure readings. Common issues that may arise include inaccurate pressure readings or leaks, which can often be addressed by re-securing connections or replacing damaged components. Following manufacturer recommendations for maintenance will help maintain the tube’s functionality and ensure the engine operates efficiently 3.

Cummins: A Brief Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive industry. Founded in 1919, the company has a long history of producing high-quality engine components and systems. Cummins is known for its commitment to innovation, quality, and reliability, making it a trusted name among truck manufacturers and operators. The company’s dedication to producing durable and efficient components is evident in products like the 3165345 Manifold Pressure Tube, which contribute to the performance and reliability of heavy-duty trucks.

Compatibility with Cummins Engines

The Manifold Pressure Tube, identified by part number 3165345, is a critical component in the engine systems of various Cummins engines. This part is designed to ensure accurate measurement and regulation of manifold pressure, which is essential for optimal engine performance and efficiency.

NH/NT 855 Engines

The NH/NT 855 engines are a series of heavy-duty diesel engines produced by Cummins. These engines are known for their robust construction and reliability, making them a popular choice in various industrial and commercial applications. The Manifold Pressure Tube (3165345) is specifically engineered to fit seamlessly within the manifold system of these engines. It ensures that the pressure readings are accurate, which is crucial for the engine control unit (ECU) to manage fuel injection and other critical functions.

The installation of the Manifold Pressure Tube in the NH/NT 855 engines involves precise alignment and secure attachment to the manifold. This ensures that the tube can effectively transmit pressure data without any leaks or obstructions, maintaining the integrity of the engine’s performance monitoring system.

Role of Part 3165345 Manifold Pressure Tube in Engine Systems

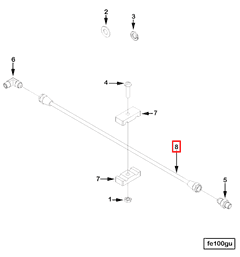

The part 3165345 Manifold Pressure Tube is an integral component in the orchestration of engine performance, specifically within the context of the Manifold Pressure Mounting Tube, Plumbing, and Air Fuel Control systems.

Integration with Manifold Pressure Mounting Tube

The Manifold Pressure Tube interfaces directly with the Manifold Pressure Mounting Tube, facilitating the transfer of pressure readings from the intake manifold to the pressure sensor. This connection ensures that the engine control unit (ECU) receives accurate data regarding the manifold pressure, which is essential for the ECU to make informed adjustments to the engine’s operation.

Role in Plumbing

Within the Plumbing system, the Manifold Pressure Tube serves as a conduit for pressure signals. It is part of a network of tubes and sensors that work in concert to maintain the engine’s optimal performance. The tube’s precise fit and secure connection to other components prevent leaks and ensure that pressure readings are consistent and reliable.

Contribution to Air Fuel Control

The Air Fuel Control system relies on precise measurements to regulate the air-fuel mixture entering the combustion chamber. The Manifold Pressure Tube contributes to this system by providing the ECU with real-time data on manifold pressure. This information is used to adjust the fuel injection timing and quantity, ensuring that the engine operates efficiently and within the desired performance parameters.

Conclusion

In summary, the Manifold Pressure Tube is a key player in the engine’s feedback loop, enabling the ECU to make dynamic adjustments that enhance engine performance, fuel efficiency, and emissions control. Its integration with the Manifold Pressure Mounting Tube, Plumbing, and Air Fuel Control systems underscores its importance in the engine’s overall functionality.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.