This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3177217 Breather Tube is engineered to enhance the operation of commercial truck engines by facilitating pressure equalization and preventing contaminant ingress within the engine compartment. This contributes to engine efficiency and longevity 1.

Basic Concepts of Breather Tubes

Breather tubes are integral to engine systems, regulating pressure and releasing accumulated gases. They maintain engine components within their designed parameters, reducing damage risks from pressure build-up and keeping contaminants away from sensitive areas 2.

Purpose of the 3177217 Breather Tube

This Cummins part is designed for pressure equalization and contamination prevention in commercial truck engines. It safely releases gases and vapors, acting as a barrier against dirt, moisture, and other contaminants that could impair engine function 3.

Key Features

The 3177217 is constructed from durable materials resistant to commercial truck environments. It features robust construction for high temperatures and pressures, and a design that ensures efficient pressure equalization and contamination prevention.

Benefits of Using the 3177217 Breather Tube

Using this part can lead to improved engine longevity, decreased maintenance requirements due to its durable construction, and enhanced engine performance through optimal operating conditions.

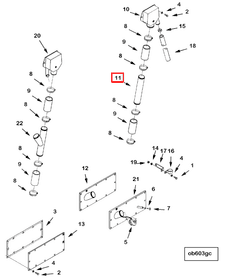

Installation Process

Installing the 3177217 requires preparing the engine compartment, aligning the tube with mounting points, securing it with appropriate fasteners, and verifying correct installation and operation. Tools may include wrenches and a torque wrench.

Troubleshooting Common Issues

Common issues like blockages or leaks can affect engine performance. Blockages may be diagnosed by checking airflow, while leaks can be identified by inspection or pressure testing. Resolution may involve cleaning, replacing damaged sections, or ensuring secure connections.

Maintenance Tips

Regular maintenance is recommended for longevity and efficiency. This includes periodic inspection for wear or damage, cleaning to remove contaminants, and verifying secure connections. Adhering to manufacturer-recommended inspection intervals can prevent issues.

Compatibility and Usage

The 3177217 is designed for specific engines and truck models. Ensuring compatibility is important for proper application and function. Detailed compatibility information should be consulted for suitability.

Cummins Corporation Overview

Cummins Inc. is a global power leader known for reliable and high-performance components that contribute to the efficiency and durability of commercial vehicles.

Role of 3177217 in Engine Systems

This part is crucial for the efficient operation of various engine systems, managing gas flow and maintaining optimal pressure levels within the crankcase.

Integration with Oil Fill and Dipstick Systems

The breather tube allows for the release of pressure built up within the crankcase, ensuring accurate oil measurement and contamination-free crankcase filling.

Breather Mounting and Crankcase Breather

Proper breather mounting is vital for venting gases from the crankcase, maintaining a stable environment and preventing pressure buildup that could lead to leaks or mechanical issues.

Interaction with Crankcase Explosion Valve

The breather tube complements the crankcase explosion valve by providing a managed release of gases under normal operating conditions, preventing uncontrolled gas escape during pressure spikes.

Dipstick Fill & Breather and Fill & Breather Mechanisms

In systems where the dipstick serves dual purposes, the breather tube ensures clear dipstick tubes for accurate oil level readings and safe filling procedures. In fill and breather arrangements, it allows for simultaneous oil addition and gas venting.

Conclusion

The 3177217 Breather Tube plays a significant role in maintaining engine efficiency and longevity by ensuring proper pressure management and contamination prevention. Its integration into various engine components underscores the importance of proper installation and maintenance for optimal engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.