This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

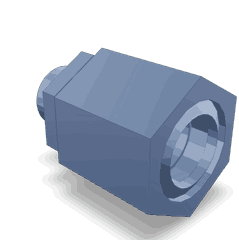

The Cummins 3179822 Tube Connector is a specialized component designed for use in commercial trucks. It plays a significant role in the operation of these vehicles by facilitating secure connections within fluid systems. Cummins Inc., a well-established manufacturer in the automotive industry, produces this connector. Known for its commitment to quality and innovation, Cummins provides components that enhance the performance and reliability of commercial vehicles 1.

Basic Concepts of Tube Connectors

Tube connectors are components used in fluid systems to join tubes and pipes, allowing for the transfer of liquids or gases. They ensure a secure and leak-free connection, which is vital for the efficient operation of various systems. Tube connectors come in different types, including compression, push-to-connect, and threaded connectors, each suited for specific applications across industries such as automotive, aerospace, and manufacturing 2.

Purpose of the 3179822 Tube Connector

The Cummins 3179822 Tube Connector is designed to play a specific role in the operation of commercial trucks. It connects various fluid systems, such as fuel, coolant, and hydraulic lines, ensuring that these systems function correctly. Reliable connections in these systems are important for maintaining system integrity and preventing leaks, which can lead to inefficiencies or safety hazards 3.

Key Features

The Cummins 3179822 Tube Connector boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes precision-machined components that facilitate a secure fit, reducing the risk of leaks. Additionally, the connector may feature unique characteristics such as integrated seals or locking mechanisms to further ensure a reliable connection.

Benefits

Using the Cummins 3179822 Tube Connector offers several benefits. It contributes to improved system efficiency by ensuring secure and leak-free connections. This can lead to reduced maintenance needs, as the likelihood of leaks and associated issues is minimized. Furthermore, the reliable performance of the connector enhances safety and reliability in truck operations, supporting consistent and efficient vehicle performance.

Installation Process

Proper installation of the Cummins 3179822 Tube Connector involves several steps to ensure a secure and leak-free connection. Begin by preparing the tubing and ensuring it is clean and free of debris. Use the appropriate tools to cut the tubing to the required length and deburr the ends. Insert the tubing into the connector, ensuring it is fully seated. Tighten the connector according to the manufacturer’s specifications, using a torque wrench if necessary, to achieve the correct tension. Finally, inspect the connection for leaks and make any necessary adjustments.

Troubleshooting and Maintenance

Common issues with tube connectors may include leaks, loose connections, or corrosion. To troubleshoot these issues, first, inspect the connection for visible signs of damage or wear. Ensure that the tubing is properly seated within the connector and that all components are tightened to the correct specifications. Regular maintenance, such as periodic inspection and cleaning, can help prolong the life of the connector. If significant wear or damage is detected, consider replacing the connector to maintain system integrity.

Compatibility and Applications

The Cummins 3179822 Tube Connector is designed for use in specific types of trucks and fluid systems. It is important to ensure compatibility with the vehicle’s existing components and systems to maintain optimal performance. The connector is engineered to work seamlessly with Cummins’ fluid systems, providing a reliable connection that supports the efficient operation of commercial trucks.

Safety Considerations

When working with tube connectors, it is important to follow proper safety practices to prevent accidents and ensure system integrity. This includes handling the components with care, using the correct tools for installation and maintenance, and following the manufacturer’s guidelines. Additionally, ensure that all connections are secure and leak-free to prevent potential hazards associated with fluid leaks.

Cummins as a Manufacturer

Cummins Inc. is a renowned manufacturer in the automotive industry, with a history of producing high-quality components. The company is known for its commitment to innovation and excellence, providing products that enhance the performance and reliability of commercial vehicles. Cummins’ reputation for quality is built on a foundation of rigorous testing, advanced manufacturing processes, and a dedication to customer satisfaction.

Tube Connector 3179822 in Cummins Engines

The Tube Connector part number 3179822, manufactured by Cummins, is a critical component in several Cummins engine models. This part is integral to the engine’s cooling system, ensuring efficient heat transfer and maintaining optimal engine performance.

K50 Series

In the K50 series engines, the Tube Connector 3179822 is designed to connect the coolant passages within the engine block. This connector ensures that coolant flows smoothly through the engine, preventing overheating and maintaining the engine’s efficiency. The precise fit and durability of the Tube Connector are essential for the longevity and reliability of the K50 engines.

Grouping of Engines

The Tube Connector 3179822 is compatible with a range of Cummins engines, including but not limited to, the K50 series. Its design allows it to fit seamlessly into various engine configurations, ensuring that coolant pathways are maintained without leaks or blockages. This compatibility extends to other Cummins engine models where similar cooling system requirements are present.

The Tube Connector 3179822 is engineered to withstand the high pressures and temperatures within the engine, making it a reliable choice for maintaining the integrity of the cooling system. Its robust construction ensures that it can endure the rigors of continuous operation, contributing to the overall performance and lifespan of the engine.

Role of Part 3179822 Tube Connector in Engine Systems

The 3179822 Tube Connector is an essential component in various engine systems, facilitating the secure and efficient connection of tubes and hoses. This part ensures that fluids, such as coolant or fuel, are transported smoothly between different sections of the engine.

In water connection systems, the 3179822 Tube Connector plays a significant role by linking the water pump to the engine block and radiator. This connection is vital for maintaining proper coolant flow, which helps in regulating engine temperature and preventing overheating.

When it comes to performance parts, the Tube Connector is often used in high-performance engine setups where precise fluid dynamics are necessary. It ensures that performance-enhancing fluids, such as specialized coolants or fuel additives, are delivered consistently and without leaks.

In the broader context of parts and their interactions within an engine, the 3179822 Tube Connector contributes to the overall reliability and efficiency of the system. By providing a secure connection point, it reduces the risk of fluid leaks, which can lead to engine damage or decreased performance.

Overall, the 3179822 Tube Connector is a fundamental component that supports the smooth operation of engine systems by ensuring secure and efficient fluid transfer between critical parts.

Conclusion

The Cummins 3179822 Tube Connector is a vital component in the operation of commercial trucks and Cummins engines. Its role in ensuring secure and leak-free connections within fluid systems contributes to the overall efficiency, safety, and reliability of these vehicles. Proper installation, maintenance, and understanding of its applications are key to maximizing the benefits of this Cummins part.

-

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.