This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Corrosion Resistor Tube 3280710, manufactured by Cummins, is a specialized component designed for use in commercial truck applications. Cummins, a well-established name in the automotive industry, is known for its high-quality and reliable parts. The 3280710 Corrosion Resistor Tube is significant in the context of truck maintenance and performance, offering enhanced durability and efficiency in harsh operating environments 1.

Basic Concepts of Corrosion Resistor Tubes

A Corrosion Resistor Tube is engineered to withstand corrosive environments, which are common in commercial trucking due to exposure to various chemicals, moisture, and road salts. The tube functions by providing a protective barrier that prevents corrosion from affecting the underlying metal surfaces. Its design incorporates materials and coatings that resist chemical reactions and physical wear, ensuring longevity and reliability in demanding conditions 2.

Purpose of the 3280710 Corrosion Resistor Tube

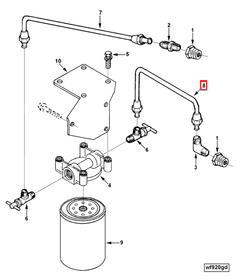

The 3280710 Corrosion Resistor Tube plays a role in the truck’s system by protecting critical components from corrosion. It is typically placed in areas where exposure to corrosive elements is high, such as near the exhaust system or in the fuel lines. The tube’s specific functions include maintaining the integrity of the system, ensuring efficient fluid flow, and protecting adjacent components from corrosive damage 3.

Key Features

The 3280710 Corrosion Resistor Tube boasts several key features that enhance its performance and durability. It is constructed from high-grade materials that offer superior resistance to corrosion. The design includes a protective coating that further shields the tube from environmental factors. Additionally, the tube is engineered to withstand high pressures and temperatures, making it suitable for rigorous commercial truck applications.

Benefits

The advantages provided by the 3280710 Corrosion Resistor Tube include improved longevity, reduced maintenance needs, and enhanced overall performance of the truck’s systems. By resisting corrosion, the tube helps maintain the efficiency and reliability of the truck, leading to fewer breakdowns and lower maintenance costs. Its durable construction ensures that it can withstand the demands of commercial use, contributing to the truck’s overall performance.

Installation Considerations

Proper installation of the 3280710 Corrosion Resistor Tube is vital to ensure optimal performance. It is important to verify compatibility with the specific truck model and system to which it will be added. Installation should follow manufacturer guidelines to ensure that the tube is securely placed and properly sealed. Attention to detail during installation will help maximize the tube’s effectiveness and longevity.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are important for prolonging the lifespan of the 3280710 Corrosion Resistor Tube. Common issues may include signs of wear, leaks, or reduced efficiency. Routine inspections can help identify these problems early, allowing for prompt repairs or replacements. Maintenance practices should include cleaning the tube and checking for any signs of corrosion or damage.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, with a history of innovation and quality. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts. Cummins is renowned for its commitment to reliability and performance, making it a trusted name among commercial truck operators and maintenance professionals.

Cummins Corrosion Resistor Tube 3280710 in Engine Applications

The Cummins Corrosion Resistor Tube 3280710 is a critical component in various engine systems, designed to protect against corrosion and ensure longevity and reliability. This part is integral to the engine’s cooling system, where it plays a vital role in maintaining the integrity of the coolant passages.

Engine Compatibility

- 6C8.3 Engines

The 6C8.3 engine, known for its robust performance and durability, incorporates the Corrosion Resistor Tube 3280710 to safeguard against the corrosive effects of coolant. This tube is strategically placed within the engine’s cooling system to prevent degradation of the coolant passages, thereby extending the engine’s operational life.

Installation and Function

In the 6C8.3 engine, the Corrosion Resistor Tube 3280710 is installed in areas where the coolant is most susceptible to corrosion. Its placement ensures that the coolant flows smoothly through the engine without causing damage to the internal components. This tube is designed to withstand the high temperatures and pressures within the engine, providing a reliable barrier against corrosion.

Importance in Engine Maintenance

Regular inspection and replacement of the Corrosion Resistor Tube 3280710 are essential for maintaining the engine’s performance. Over time, exposure to coolant can lead to corrosion, which can compromise the structural integrity of the engine. By using a high-quality corrosion resistor tube, such as the one manufactured by Cummins, engine operators can ensure that their engines remain in optimal condition, reducing the risk of costly repairs and downtime.

Role of Part 3280710 Corrosion Resistor Tube in Engine Systems

The part 3280710 Corrosion Resistor Tube is integral to the efficient operation of various engine systems. It is specifically designed to handle the corrosive environments often encountered in engine compartments.

In fuel systems, the Corrosion Resistor Tube ensures that fuel lines remain intact and free from corrosion, which can be caused by the ethanol content in modern fuels. This helps maintain fuel integrity and pressure, leading to consistent engine performance.

Within the cooling system, this tube plays a significant role in transporting coolant without succumbing to the corrosive effects of the coolant additives. This ensures that the engine maintains optimal temperature, preventing overheating and potential engine damage.

In brake systems, the Corrosion Resistor Tube is employed in hydraulic lines. It resists the corrosive nature of brake fluid, ensuring that brake performance remains reliable and safe over time.

Additionally, in emission control systems, this tube is used in various lines that carry exhaust gases and recirculated emissions. Its resistance to corrosion ensures that these systems function correctly, contributing to reduced emissions and compliance with environmental regulations.

Overall, the integration of the Corrosion Resistor Tube in these systems enhances durability and reliability, making it a valuable component in maintaining the overall health and performance of engine systems.

Conclusion

The 3280710 Corrosion Resistor Tube by Cummins is a vital component in commercial truck applications, offering significant benefits in terms of durability, efficiency, and reliability. Its role in protecting critical engine components from corrosion ensures that trucks remain in optimal condition, reducing maintenance needs and operational costs. Proper installation, regular maintenance, and timely troubleshooting are essential practices to maximize the effectiveness of this part. Cummins’ commitment to quality and innovation underscores the importance of using reliable components like the 3280710 Corrosion Resistor Tube in maintaining the performance and longevity of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.