This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Corrosion Resistant Tube 3281570, manufactured by Cummins, is a specialized component designed for use in commercial truck applications. Cummins, a well-established name in the automotive industry, is known for producing high-quality components that enhance the performance and durability of heavy-duty vehicles. This part is significant in maintaining the integrity and efficiency of truck systems, particularly in environments where corrosion can be a prevalent issue.

Basic Concepts of Corrosion Resistant Tubes

Corrosion resistant tubes are designed to withstand the degrading effects of corrosive environments. These tubes are typically made from materials or coated with substances that resist chemical reactions that lead to corrosion. In heavy-duty truck systems, these tubes play a role in transporting fluids and gases that are essential for the operation of various systems, including the engine, transmission, and hydraulic systems. Their resistance to corrosion helps in maintaining the longevity and reliability of these systems 1.

Purpose of the 3281570 Corrosion Resistant Tube

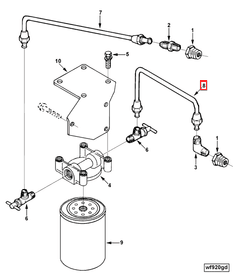

The 3281570 Corrosion Resistant Tube is specifically designed to facilitate the transport of fluids within a truck’s system. It is strategically placed in areas where it is exposed to potentially corrosive elements, such as moisture, chemicals, or extreme temperatures. This tube interacts with other components by providing a durable pathway for fluid transfer, which is vital for the consistent operation of the truck’s systems.

Key Features

The 3281570 Corrosion Resistant Tube boasts several key features that enhance its performance. It is constructed from a material composition that offers superior resistance to corrosion. The design elements include precise dimensions and smooth internal surfaces to ensure efficient fluid flow. Additionally, it may feature unique characteristics such as reinforced sections for added strength or specialized coatings for enhanced protection against environmental factors.

Benefits

The advantages of the 3281570 Corrosion Resistant Tube include improved durability in harsh operating conditions, resistance to a variety of environmental factors that can lead to corrosion, and a contribution to the overall efficiency of the truck’s systems. Its robust construction and corrosion-resistant properties help in reducing the need for frequent replacements and maintenance, which can lead to cost savings and increased uptime for commercial operations 2.

Installation

Proper installation of the 3281570 Corrosion Resistant Tube involves several guidelines and best practices. Preparatory steps may include cleaning the installation area and ensuring that all mating surfaces are free from contaminants. The use of appropriate tools and fittings is necessary to secure the tube in place without damaging it. Following the manufacturer’s instructions ensures that the tube is installed correctly and functions as intended within the truck’s system.

Troubleshooting

Common issues that may arise with the 3281570 Corrosion Resistant Tube include leaks, blockages, or signs of corrosion. Identifying these problems involves regular inspection and monitoring of the tube’s condition. Recommended solutions may range from cleaning and repairing minor damage to replacing the tube if it is compromised beyond repair. Prompt attention to these issues helps in maintaining the tube’s performance and preventing more significant system failures.

Maintenance

Routine maintenance practices for the 3281570 Corrosion Resistant Tube are crucial for ensuring its longevity and optimal performance. This includes regular inspection schedules to check for any signs of wear, corrosion, or damage. Care tips may involve cleaning the tube and its surroundings, applying protective coatings if necessary, and ensuring that all connections are secure and leak-free. Consistent maintenance helps in identifying potential issues before they lead to system failures.

Cummins Overview

Cummins is a reputable manufacturer in the automotive industry, known for its commitment to producing high-quality components. With a strong reputation for reliability and performance, Cummins components are widely used in commercial and heavy-duty applications. The company’s dedication to innovation and quality is reflected in its product line, which includes a variety of parts designed to enhance the efficiency and durability of vehicles.

Cummins Corrosion Resistant Tube 3281570 in Engine Applications

The Cummins Corrosion Resistant Tube 3281570 is a critical component in various engine systems, ensuring durability and longevity in harsh environments. This part is specifically designed to withstand the corrosive effects of engine fluids and gases, making it an essential element in maintaining the integrity of the engine’s cooling and exhaust systems.

Application in 6C8.3 Engines

In the 6C8.3 engine, the Corrosion Resistant Tube 3281570 plays a pivotal role in the engine’s cooling system. It is engineered to connect different parts of the cooling system, ensuring efficient heat transfer and preventing leaks. The tube’s resistance to corrosion is particularly important in this engine, as it operates under high temperatures and pressures, which can accelerate the degradation of standard materials.

Grouping with Other Cummins Engines

The 3281570 tube is also compatible with a range of other Cummins engines, where it serves similar functions. In these engines, the tube is often used in the exhaust system, where it must endure high temperatures and corrosive exhaust gases. Its robust construction ensures that it can maintain its structural integrity over extended periods, reducing the need for frequent replacements and minimizing downtime.

The use of the Corrosion Resistant Tube 3281570 across various Cummins engines highlights its versatility and importance in maintaining engine performance and reliability. Its ability to resist corrosion and withstand extreme conditions makes it a preferred choice for critical engine components.

Role of Part 3281570 Corrosion Resistant Tube in Engine Systems

Part 3281570 Corrosion Resistant Tube is integral to the efficient and reliable operation of various engine systems. Its primary function is to facilitate the transfer of fluids, gases, and other substances within the engine while resisting corrosion, which is vital for maintaining system integrity and performance.

Fuel System Integration

In the fuel system, the corrosion-resistant tube ensures the safe and efficient delivery of fuel from the tank to the engine. This is particularly important in environments where fuel may contain contaminants that could accelerate corrosion. The tube’s resistance to corrosion helps prevent leaks and maintains consistent fuel pressure, which is essential for optimal combustion and engine performance.

Cooling System Functionality

Within the cooling system, the tube plays a significant role in circulating coolant throughout the engine. This helps in dissipating heat generated during combustion, preventing overheating. The corrosion-resistant properties of the tube ensure that it can withstand the harsh conditions created by the coolant, which often contains additives to enhance its performance and protect metal components from corrosion.

Emissions Control System

In the emissions control system, the tube is used to transport exhaust gases to various components, such as the catalytic converter and oxygen sensors. Corrosion resistance is key here, as exhaust gases contain acidic compounds that can degrade standard tubing materials. The durable nature of the tube ensures that emissions are effectively managed and that the engine meets environmental regulations.

Lubrication System

The lubrication system relies on the corrosion-resistant tube to deliver oil to critical engine components, ensuring they are properly lubricated and cooled. This is essential for reducing friction and wear, which can lead to increased efficiency and longevity of the engine. The tube’s ability to resist corrosion helps maintain the purity of the oil, preventing contamination that could compromise lubrication.

Brake System

In brake systems, particularly those that use fluid to transmit force, the corrosion-resistant tube ensures that brake fluid is delivered without contamination or leakage. This is vital for maintaining consistent brake performance and safety. The tube’s resistance to corrosion helps in preserving the integrity of the brake fluid, which can be susceptible to degradation over time.

Electrical Systems

Though not directly related to fluid transfer, the corrosion-resistant properties of the tube can also be beneficial in electrical systems where wiring and connectors may be exposed to moisture and other corrosive elements. Using such tubing for protective conduits can enhance the durability and reliability of electrical connections within the engine compartment.

By incorporating Part 3281570 Corrosion Resistant Tube into these systems, engineers and mechanics can ensure enhanced durability, reliability, and performance of the engine, ultimately contributing to the overall efficiency and longevity of the vehicle.

Conclusion

The 3281570 Corrosion Resistant Tube by Cummins is a vital component in the maintenance and operation of commercial truck and engine systems. Its corrosion-resistant properties, robust construction, and versatile applications across various engine systems make it an indispensable part for ensuring the durability, reliability, and efficiency of heavy-duty vehicles. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this Cummins part, contributing to the overall performance and longevity of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.