This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

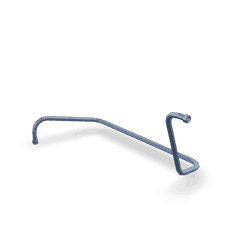

The Compressor Water Inlet Tube, identified by part number 3285148, is a component manufactured by Cummins, a prominent name in the automotive and heavy-duty truck industry. This part plays a role in the operation of heavy-duty truck engines by facilitating the introduction of water into the compressor system. Its function is integral to the overall engine system, contributing to various aspects of engine performance and efficiency 1.

Basic Concepts and Functionality

The Compressor Water Inlet Tube operates on the principle of introducing water into the compressor system of an engine. Water is injected into the compressor to cool the intake air, which increases air density and enhances combustion efficiency. This process also helps in reducing the formation of nitrogen oxides (NOx), a common byproduct of combustion 2. The tube interacts with other engine components, ensuring a seamless flow of water into the compressor system.

Purpose of the Compressor Water Inlet Tube

The Compressor Water Inlet Tube serves several functions within a truck engine. It contributes to engine efficiency by ensuring that the intake air is adequately cooled, which allows for more efficient combustion. Additionally, it plays a role in the engine’s cooling system by helping to maintain optimal operating temperatures. Proper water introduction into the compressor system is vital for achieving these benefits, highlighting the importance of this component in engine operation 3.

Key Features

The Cummins Compressor Water Inlet Tube (Part #3285148) is designed with several features that enhance its functionality and durability. These include a robust construction that can withstand the high pressures and temperatures within the engine system. The tube is made from materials that offer excellent resistance to corrosion and wear, ensuring long-term reliability. Its design also facilitates easy installation and maintenance, contributing to its overall effectiveness.

Benefits

Utilizing the Cummins Compressor Water Inlet Tube in heavy-duty truck engines offers several advantages. It contributes to improved engine performance by enhancing combustion efficiency and reducing emissions. The tube’s durable construction and reliable operation also add to the engine’s reliability and longevity. Additionally, by improving engine efficiency and reducing the need for frequent maintenance, it can offer cost-saving benefits over time.

Installation and Compatibility

Proper installation of the Compressor Water Inlet Tube is crucial for its effective operation. It is designed to be compatible with various Cummins engine models, ensuring a seamless integration into the engine system. During installation, it is important to follow manufacturer guidelines to ensure proper fitment and function. Special considerations may include ensuring the tube is securely fastened and that all connections are properly sealed to prevent leaks.

Maintenance and Troubleshooting

Routine maintenance of the Compressor Water Inlet Tube is important for ensuring its optimal performance. This may include regular inspections for signs of wear or damage, such as corrosion or leaks. Common issues that may arise include blockages or restrictions in the water flow, which can be addressed by cleaning or replacing the tube as necessary. Monitoring the tube’s condition and addressing any issues promptly can help maintain engine performance and efficiency.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to innovation, quality, and customer satisfaction. The company has a long history of producing diesel engines and related components, earning a reputation for reliability and performance. Cummins’ dedication to advancing technology and meeting the needs of its customers has solidified its position as a leader in the industry.

Cummins Compressor Water Inlet Tube (Part 3285148) Compatibility

The Cummins Compressor Water Inlet Tube, identified by part number 3285148, is a critical component in the cooling system of certain engine models. This part is designed to facilitate the flow of water into the engine’s compressor, ensuring efficient cooling and optimal performance.

Engine Compatibility

The Compressor Water Inlet Tube (3285148) is specifically engineered to fit the following Cummins engine models:

- 6B5.9 Series

This part is integral to the cooling system of the 6B5.9 engines, ensuring that the compressor receives the necessary coolant to maintain its operational temperature. The design and fitment of this tube are crucial for the engine’s overall performance and longevity.

Grouping of Engines

The 6B5.9 series engines are part of a broader family of Cummins engines known for their reliability and efficiency in various industrial and commercial applications. The Compressor Water Inlet Tube (3285148) is tailored to meet the specific requirements of these engines, ensuring seamless integration and optimal performance.

By ensuring that the compressor receives the correct amount of coolant, this part helps to prevent overheating and maintain the engine’s efficiency. The precise fitment and design of the Compressor Water Inlet Tube (3285148) are essential for the reliable operation of the 6B5.9 engines.

Role of Part 3285148 Compressor Water Inlet Tube in Engine Systems

The Compressor Water Inlet Tube (part 3285148) is integral to the efficient operation of the compressor coolant plumbing system within engine systems. This component facilitates the directed flow of coolant into the compressor, ensuring optimal thermal management.

Interaction with Compressor Coolant Plumbing

-

Coolant Distribution: The Compressor Water Inlet Tube is responsible for channeling coolant from the engine’s cooling system into the compressor. This ensures that the compressor remains at an optimal operating temperature, enhancing its efficiency and longevity.

-

Thermal Regulation: By providing a consistent supply of coolant, the tube helps in maintaining the thermal balance of the compressor. This is particularly important in high-stress environments where the compressor is subjected to extreme temperatures.

-

System Integration: The tube is designed to interface seamlessly with other components of the coolant plumbing system, such as the coolant passages within the compressor housing and the main coolant lines. This integration ensures a cohesive and efficient coolant flow throughout the system.

-

Pressure Management: The design of the Compressor Water Inlet Tube also contributes to the management of coolant pressure within the system. Proper pressure regulation is essential for preventing leaks and ensuring that the coolant reaches all necessary areas of the compressor.

-

Maintenance and Reliability: The presence of the Compressor Water Inlet Tube simplifies maintenance procedures. Its dedicated role in the coolant system allows for easier inspection and replacement, should any issues arise, thereby contributing to the overall reliability of the engine system.

Conclusion

The Compressor Water Inlet Tube (part number 3285148) is a vital component in the operation of heavy-duty truck engines, particularly those manufactured by Cummins. Its role in facilitating the introduction of water into the compressor system contributes significantly to engine performance and efficiency. By ensuring proper cooling and thermal management, this part helps maintain optimal engine operation, reduce emissions, and enhance overall reliability. Proper installation, maintenance, and understanding of its compatibility with specific engine models are essential for maximizing the benefits of this Cummins part.

-

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Reif, Konrad (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ -

Hilgers, Michael. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.