This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

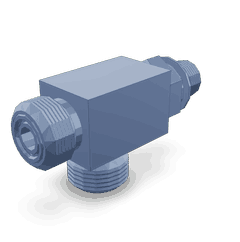

The Cummins 3287200 Tube Connector Tee is a specialized component designed for use in commercial truck systems. Manufactured by Cummins Inc., a leader in the diesel engine and power generation equipment industry, this tube connector tee serves a specific function within the intricate network of a truck’s fluid systems. Understanding its purpose, features, and proper usage is vital for maintaining the efficiency and reliability of commercial vehicles.

Basic Concepts of Tube Connector Tee

A Tube Connector Tee is a fitting used in fluid systems to merge or split fluid flow. It operates by allowing fluid to enter one port and exit through two others, or vice versa, facilitating the distribution or combination of fluids within a system. In the context of a truck’s hydraulic or fuel system, the tube connector tee enables the efficient management of fluid dynamics, ensuring that components receive the necessary fluid at the correct pressure and flow rate 1.

Purpose of the 3287200 Tube Connector Tee

The Cummins 3287200 Tube Connector Tee plays a role in the operation of a truck by facilitating the connection between different sections of the hydraulic or fuel system. Its application allows for the merging of fluid lines, which is crucial for systems that require the distribution of fluid to multiple components or the combination of fluid streams from different sources. This component ensures that the system operates smoothly, with minimal disruption to fluid flow 2.

Key Features

The Cummins 3287200 Tube Connector Tee is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The connection types are designed for secure fitting, reducing the risk of leaks. Additionally, its design specifications are tailored to meet the demands of commercial truck systems, providing a reliable solution for fluid management 3.

Benefits

Utilizing the Cummins 3287200 Tube Connector Tee offers several advantages. It contributes to improved system efficiency by ensuring smooth and uninterrupted fluid flow. Its reliable design enhances the overall reliability of the truck’s fluid systems. Furthermore, the ease of installation makes it a practical choice for maintenance and repair tasks, reducing downtime and facilitating quick system restoration.

Installation Process

Installing the Cummins 3287200 Tube Connector Tee requires careful attention to detail to ensure a secure fit. The process involves cleaning the connection points, applying the appropriate sealant if necessary, and then connecting the tee to the fluid lines. Tools such as wrenches may be required to tighten the connections. Following the manufacturer’s guidelines for torque specifications ensures that the connections are secure without risking damage to the fitting or the lines.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3287200 Tube Connector Tee, regular maintenance is recommended. This includes inspecting the fitting for signs of wear or corrosion, checking for leaks, and ensuring that all connections remain tight. Cleaning the fitting and surrounding areas can prevent the buildup of debris that may affect performance. Adhering to these maintenance practices helps maintain the efficiency of the truck’s fluid systems.

Troubleshooting Common Issues

Common issues associated with the Cummins 3287200 Tube Connector Tee may include leaks or blockages. Leaks can often be addressed by re-tightening the connections or replacing seals. Blockages may require disassembling the fitting to clear any obstructions. Regular inspections and maintenance can help identify and resolve these issues before they lead to more significant problems.

Compatibility and Applications

The Cummins 3287200 Tube Connector Tee is designed for use in specific types of trucks and systems. It is commonly applied in hydraulic and fuel systems where fluid distribution or combination is required. Ensuring compatibility with the truck’s system is crucial for optimal performance and reliability.

Safety Considerations

When working with the Cummins 3287200 Tube Connector Tee, it is important to observe safety guidelines and precautions. This includes handling fluids carefully to avoid spills and ensuring that the system is depressurized before making any connections or disconnections. Adhering to these safety practices helps protect both the technician and the equipment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles.

Role of Part 3287200 Tube Connector Tee in Engine Systems

The 3287200 Tube Connector Tee is an essential component in the integration and functionality of various engine systems. Its primary role is to facilitate the connection and distribution of fluids or gases within the engine, ensuring efficient operation and performance.

Exhaust Outlet Accessories

In the context of exhaust outlet accessories, the 3287200 Tube Connector Tee plays a significant role in managing the flow of exhaust gases. It allows for the merging or splitting of exhaust streams, which is vital for balancing the exhaust flow from multiple cylinders or banks in a multi-cylinder engine. This balanced flow helps in reducing backpressure and enhancing the efficiency of the exhaust system. Additionally, it aids in the proper functioning of exhaust gas recirculation (EGR) systems by providing a reliable connection point for EGR tubes, ensuring that exhaust gases are recirculated effectively to reduce emissions 4.

Turbocharger Plumbing

When it comes to turbocharger plumbing, the 3287200 Tube Connector Tee is instrumental in the distribution of intake air. It enables the connection of multiple air intake paths, which is particularly useful in engines with twin-turbo setups. By allowing the merging of air streams from two turbochargers, it ensures that the air charge is evenly distributed to the engine’s cylinders. This even distribution is key to maximizing the efficiency and power output of the turbochargers. Furthermore, it assists in the integration of intercooler systems by providing a junction point for the intake and outlet tubes, facilitating the cooling of compressed air before it enters the engine, thereby improving overall engine performance and reliability.

Conclusion

The Cummins 3287200 Tube Connector Tee is a critical component in the maintenance and operation of commercial truck fluid systems. Its design, features, and applications highlight the importance of reliable fluid management in ensuring the efficiency and reliability of commercial vehicles. Regular maintenance, proper installation, and adherence to safety guidelines are essential for maximizing the performance and longevity of this part.

-

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Vehicle Crash Dynamics, Matthew Huang, CRC Press, 2002

↩ -

Troubleshooting and Repairing Diesel Engines, Paul Dempsey, McGraw-Hill, 2008

↩ -

Fault Code Troubleshooting Manual, Bulletin Number 5411250, Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.