3331881

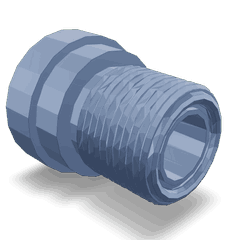

Tube Fitting Reducer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tube Fitting Reducer 3331881, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the automotive industry, produces a range of parts that contribute to the efficiency and reliability of commercial vehicles. This part plays a role in connecting and managing fluid systems within trucks 1.

Basic Concepts of Tube Fitting Reducers

A tube fitting reducer is a component used in fluid systems to connect tubes of different diameters. Its general function is to facilitate the transition between larger and smaller tubes, ensuring a smooth flow of fluids. This is achieved through a tapered or stepped design that allows for a gradual reduction in diameter, minimizing turbulence and potential leakage in the system 2.

Purpose and Role in Truck Operations

The 3331881 Tube Fitting Reducer serves a specific purpose in the fluid systems of commercial trucks. It is utilized in various systems including fuel, hydraulic, and coolant circuits. By connecting tubes of different sizes, it ensures that the flow of fluids is maintained efficiently, which is vital for the operation of these systems. In fuel systems, it helps in the delivery of fuel to the engine; in hydraulic systems, it aids in the operation of various truck components; and in coolant systems, it assists in maintaining the engine temperature 3.

Key Features

The 3331881 Tube Fitting Reducer is characterized by several key features that enhance its functionality and durability. These include its material composition, which is designed to withstand the pressures and temperatures typical in truck applications. The connection types it supports are tailored to fit specific tube configurations, and its pressure ratings are set to ensure safe and reliable operation. The design specifications of the reducer are optimized for performance in demanding environments 4.

Benefits

Using the 3331881 Tube Fitting Reducer offers several benefits. It contributes to improved system efficiency by ensuring a smooth transition between tubes of different diameters. This reduces the risk of leakage and enhances the overall performance of the fluid systems. Additionally, its durable construction allows it to withstand the high-stress conditions typical in heavy-duty truck applications, leading to a longer service life 1.

Installation Considerations

When installing the 3331881 Tube Fitting Reducer, it is important to follow guidelines and best practices to ensure proper function. This includes adhering to torque specifications to secure connections without over-tightening, which could damage the fitting. Alignment procedures should be carefully followed to ensure that the reducer is correctly positioned within the system. Compatibility with other system components must also be considered to maintain system integrity 2.

Troubleshooting and Maintenance

Common issues with tube fitting reducers can include leaks, blockages, or damage due to wear and tear. Diagnostic procedures for identifying these problems may involve visual inspections, pressure tests, or flow analysis. Maintenance practices to ensure the longevity and optimal performance of the 3331881 Tube Fitting Reducer include regular checks for signs of wear, ensuring connections are secure, and replacing the reducer if it shows signs of significant damage or failure 3.

Regulatory and Safety Considerations

The use of tube fitting reducers in commercial truck applications is subject to regulatory standards and safety considerations. Compliance with industry standards ensures that the components used in these systems meet the necessary safety and performance criteria. Best practices for safe operation include regular maintenance, proper installation, and adherence to manufacturer guidelines to prevent accidents and ensure the reliability of the truck’s fluid systems 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components that contribute to the efficiency, reliability, and performance of commercial vehicles. Cummins’ commitment to quality is evident in its rigorous manufacturing processes and the durability of its products.

Cummins Tube Fitting Reducer 3331881 Compatibility

The Cummins Tube Fitting Reducer part number 3331881 is designed to be compatible with a range of Cummins diesel engines. This part is integral in ensuring the proper functioning of the engine’s cooling and exhaust systems by facilitating the connection between different diameter tubes.

Compatibility with Cummins Engines

- QSK38 CM2150 MCRS: The Tube Fitting Reducer 3331881 is engineered to fit seamlessly with the QSK38 CM2150 MCRS engine, providing a reliable connection for the cooling and exhaust systems.

- QSK45 CM500: This part is also compatible with the QSK45 CM500 engine, ensuring efficient fluid flow and pressure management within the engine’s systems.

- QSK60 CM500: The QSK60 CM500 engine benefits from the use of the Tube Fitting Reducer 3331881, which helps maintain the integrity of the engine’s cooling and exhaust pathways.

- QSK60 CM850 MCRS and QSK60G: Both the QSK60 CM850 MCRS and QSK60G engines are designed to integrate the Tube Fitting Reducer 3331881, ensuring optimal performance and durability.

- QSK78 CM500: The Tube Fitting Reducer 3331881 is also suitable for the QSK78 CM500 engine, providing a critical connection point in the engine’s systems.

- QSK95 CM2350 K111: This part is compatible with the QSK95 CM2350 K111 engine, ensuring that the engine’s cooling and exhaust systems operate efficiently.

By ensuring compatibility with these engines, the Tube Fitting Reducer 3331881 plays a vital role in maintaining the overall performance and longevity of the engine.

Role of Part 3331881 Tube Fitting Reducer in Engine Systems

In the intricate network of an engine system, the part 3331881 Tube Fitting Reducer serves as a vital connector, facilitating the seamless integration of various components. This reducer is instrumental in managing the flow dynamics between different plumbing systems associated with the turbocharger.

Turbocharger Plumbing

Within the turbocharger plumbing system, the Tube Fitting Reducer ensures a smooth transition between pipes of varying diameters. This is essential for maintaining consistent fluid flow, which is vital for the efficient operation of the turbocharger. By reducing the diameter at specific junctures, it helps in regulating the pressure and flow rate, thereby optimizing the performance of the turbocharger.

Turbocharger Coolant Plumbing

In the context of turbocharger coolant plumbing, the reducer plays a significant role in thermal management. It allows for the precise control of coolant flow, which is necessary to maintain the turbocharger’s operating temperature within safe limits. This is particularly important in high-performance engines where the turbocharger is subjected to extreme temperatures.

Turbocharger Oil Plumbing

For the turbocharger oil plumbing system, the Tube Fitting Reducer is key in ensuring the proper lubrication of turbocharger components. It aids in adjusting the oil flow to meet the specific lubrication requirements of the turbocharger bearings and other moving parts. This not only enhances the efficiency of the turbocharger but also contributes to its longevity by reducing wear and tear.

Conclusion

In summary, the part 3331881 Tube Fitting Reducer is an essential component in the engine system, playing a pivotal role in the efficient operation of turbocharger plumbing, coolant, and oil systems. Its ability to adapt to varying flow requirements makes it indispensable in modern engine designs.

-

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩ ↩ -

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ ↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ ↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.