This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3425317 Tube Connector is a specialized component designed for commercial truck operations. It facilitates the connection between various fluid system components, ensuring the efficient transfer of fluids such as coolant, fuel, and hydraulic fluid. This connector maintains system integrity and performance, contributing to the overall reliability and efficiency of truck operations 2.

Basic Concepts of Tube Connectors

Tube connectors are integral to fluid systems, joining tubes and components securely. They create a sealed connection that allows fluids to flow without leakage. In truck infrastructure, tube connectors maintain the functionality of critical systems, including the engine, transmission, and hydraulic systems 3.

Role of the 3425317 Tube Connector in Truck Operation

The Cummins 3425317 Tube Connector ensures the seamless transfer of fluids within a truck’s fluid systems. It connects tubes and components to support the efficient operation of the truck’s engine and other systems. By providing a secure and leak-free connection, this connector maintains the performance and reliability of the truck’s fluid systems 1.

Key Features

The Cummins 3425317 Tube Connector features a robust material composition that resists corrosion and wear, a design that ensures a tight seal, and integrated gaskets or O-rings that prevent leaks. These features enhance its performance and durability, allowing it to withstand the demanding conditions of commercial truck operations 2.

Benefits of Using the 3425317 Tube Connector

Incorporating the Cummins 3425317 Tube Connector into truck systems offers several advantages, including improved efficiency in fluid transfer, enhanced reliability due to its durable construction, and ease of maintenance thanks to its design. The connector’s secure seal reduces the risk of fluid leaks, which can lead to system failures or inefficiencies 3.

Installation Considerations

When installing the Cummins 3425317 Tube Connector, it is important to follow guidelines and best practices to ensure compatibility with other components and to achieve a secure connection. This may involve using specific tools or equipment to properly align and tighten the connector. Careful attention to these details during installation can help prevent common issues and ensure the connector functions as intended 1.

Troubleshooting Common Issues

Common problems associated with tube connectors, including the Cummins 3425317 model, can include leaks, improper sealing, or damage to the connector. Practical solutions for addressing these issues may involve inspecting the connector for signs of wear or damage, ensuring it is properly aligned and tightened, or replacing gaskets or O-rings if necessary. Regular maintenance and inspection can help identify and resolve these issues before they lead to more significant problems 2.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3425317 Tube Connector, regular maintenance is recommended. This includes routine inspections for signs of wear, corrosion, or damage, as well as cleaning the connector to remove any debris or buildup that could affect its performance. Following these maintenance tips can help maintain the efficiency and reliability of the truck’s fluid systems 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines for on-highway, off-highway, and stationary applications, as well as filtration and emission solutions. Cummins’ dedication to advancing technology and improving the way the world moves is evident in its diverse portfolio of products and services 1.

Role of Part 3425317 Tube Connector in Engine Systems

The Cummins 3425317 Tube Connector is integral to the efficient operation of various engine systems. It facilitates the secure connection between different components, ensuring optimal performance and reliability.

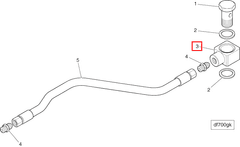

Integration with the Drive System

In the drive system, the Tube Connector maintains the integrity of fluid transfer pathways. It connects the lubricating oil assembly tube to other components, ensuring a consistent flow of lubricants to critical moving parts. This helps in reducing friction and wear, thereby enhancing the longevity and efficiency of the drive system 2.

Function in the Front Gear Train Accessory

For the front gear train accessory, the Tube Connector is essential for linking the oil assembly tube to the gear assembly housing. This connection is vital for delivering lubricants directly to the gear teeth, which are subject to high stress and friction. Proper lubrication ensures smooth operation and prevents premature wear of the gears 3.

Role in the Gear Assembly Housing

Within the gear assembly housing, the Tube Connector aids in the distribution of lubricants to various points within the housing. This ensures that all moving components within the housing are adequately lubricated, which is necessary for maintaining operational efficiency and preventing damage due to metal-on-metal contact 1.

Importance in the Lubricating Oil Assembly Tube

The Tube Connector is a key component in the lubricating oil assembly tube system. It provides a reliable connection point for the tube, allowing for the efficient transfer of lubricant from the reservoir to the points of need within the engine. This ensures that all critical components receive the necessary lubrication to function smoothly and efficiently 2.

Contribution to the Oil Assembly Tube

Finally, in the oil assembly tube, the Tube Connector ensures that the oil flow is uninterrupted and secure. This is important for maintaining the pressure and volume of oil required for the proper functioning of the engine’s lubrication system. The consistent flow of oil is essential for cooling, cleaning, and lubricating the engine’s internal components 3.

Conclusion

The Cummins 3425317 Tube Connector plays a crucial role in maintaining the efficiency and reliability of commercial truck fluid systems. Its robust design, key features, and benefits make it an essential component for ensuring the seamless operation of truck engines and other systems. Regular maintenance and proper installation are vital to maximizing the performance and longevity of this connector.

-

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩ ↩ ↩ ↩ -

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩ ↩ ↩ ↩ ↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.