This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

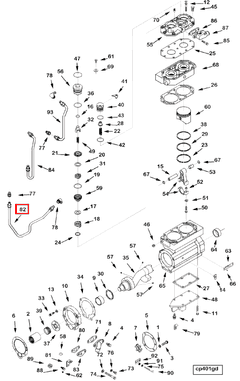

The Compressor Water Outlet Tube, identified by part number 3626610, is a component manufactured by Cummins. This part is integral to the cooling systems of heavy-duty trucks, ensuring efficient operation and longevity of the engine. Cummins, a reputable manufacturer in the automotive industry, is known for producing high-quality components that enhance the performance and reliability of vehicles 3.

Function and Operation

The Compressor Water Outlet Tube operates by directing the flow of coolant from the compressor to other parts of the engine cooling system. This tube ensures that coolant is evenly distributed, which helps in maintaining optimal engine temperature. Its operation is straightforward yet vital for the overall efficiency of the truck’s cooling system 1.

Purpose of the Compressor Water Outlet Tube

The primary role of the Compressor Water Outlet Tube is to facilitate the movement of coolant within the truck’s engine system. By ensuring that coolant reaches all necessary components, it contributes to the effective cooling of the engine, which is crucial for preventing overheating and ensuring smooth operation 2.

Key Features

The Compressor Water Outlet Tube is designed with several key features that enhance its performance. It is typically made from durable materials that can withstand high temperatures and pressures. The design includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to handle the rigors of heavy-duty use.

Benefits

The advantages of using the Compressor Water Outlet Tube include improved coolant circulation, which leads to better engine temperature management. This results in enhanced engine protection against overheating and increased system efficiency. The tube’s robust construction also ensures longevity and reliability in demanding conditions.

Installation Considerations

Proper installation of the Compressor Water Outlet Tube is important for its effective function. It should be placed according to the manufacturer’s specifications to ensure correct coolant flow. Secure fitting is crucial to prevent leaks, which could lead to inefficient cooling and potential engine damage.

Maintenance and Troubleshooting

Routine maintenance of the Compressor Water Outlet Tube involves regular inspection for signs of wear or damage. Ensuring that all connections are tight and free from leaks is also important. If issues arise, such as reduced coolant flow or leaks, troubleshooting may involve checking for blockages or damage to the tube and making necessary repairs or replacements.

Common Issues and Solutions

Frequent problems with the Compressor Water Outlet Tube can include leaks, blockages, or damage from wear and tear. Solutions typically involve inspecting the tube for any visible damage, cleaning or replacing blockages, and ensuring all connections are secure. Preventive measures include regular maintenance checks and using high-quality replacement parts when necessary.

Cummins Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive industry. The company has a history of innovation and commitment to producing high-quality components. Cummins’ products are designed to meet the demanding requirements of heavy-duty applications, ensuring reliability and performance in various operating conditions 3.

Role of Part 3626610 Compressor Water Outlet Tube in Engine Systems

The part 3626610 Compressor Water Outlet Tube is an integral component in the efficient operation of compressor systems, particularly in scenarios where water is utilized for cooling or as part of the compression process. This tube facilitates the directed flow of water from the compressor, ensuring that the water, after serving its purpose within the compressor, is efficiently routed away.

In compressor systems, the water outlet tube works in conjunction with the compressor itself, the air pathways, and the compressor water supply plumbing. As the compressor operates, it generates heat, which if not managed properly, can lead to reduced efficiency and potential damage. The water outlet tube plays a significant role in this heat management process by ensuring that the water used for cooling is effectively circulated and then expelled from the system.

The interaction between the compressor water outlet tube and the compressor water supply plumbing is particularly noteworthy. The supply plumbing brings water into the system, where it is used to cool the compressor during operation. Once the water has absorbed heat, the outlet tube ensures its prompt removal, preventing any buildup of hot water that could impair the compressor’s performance.

Furthermore, the efficient operation of the air pathways within the compressor system is also influenced by the proper functioning of the water outlet tube. By ensuring that the compressor remains at an optimal temperature, the tube indirectly supports the consistent and efficient compression of air. This is vital for the overall performance of the engine system, as it ensures that the air being compressed is done so under the right conditions, leading to more effective engine operation.

Conclusion

In summary, the Compressor Water Outlet Tube part number 3626610 is a key component in maintaining the operational integrity of compressor systems. Its role in facilitating the efficient flow of water away from the compressor ensures that the system remains cool, operates efficiently, and contributes to the overall performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.