This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Scavenge Outlet Tube, identified by part number 3626619, is a component manufactured by Cummins, a leading name in the automotive industry, particularly renowned for its heavy-duty truck engines. This tube is integral to the engine’s lubrication system, facilitating the efficient removal of contaminants and ensuring optimal engine performance 1.

Basic Concepts

At the heart of the Scavenge Outlet Tube’s function is the principle of scavenging. Scavenging refers to the process of removing unwanted substances, such as contaminants and excess oil, from the engine’s crankcase. The Scavenge Outlet Tube plays a role in this process by directing these substances away from the engine, thereby maintaining a clean and efficient lubrication system 2.

Purpose and Function

The Scavenge Outlet Tube serves a pivotal role in the operation of a truck engine. It facilitates the removal of contaminants that accumulate within the engine’s lubrication system. By ensuring that these contaminants are efficiently removed, the tube helps maintain the integrity of the engine’s lubrication, reducing wear on engine components and enhancing overall engine efficiency 3.

Key Features

The design of the Scavenge Outlet Tube incorporates several features that enhance its performance and durability. Constructed from high-quality materials, the tube is resistant to corrosion and wear, ensuring long-term reliability. Its design allows for efficient scavenging, minimizing the risk of contaminants re-entering the lubrication system.

Benefits

The incorporation of the Scavenge Outlet Tube into a truck engine’s design offers several advantages. It contributes to improved engine efficiency by ensuring that the lubrication system remains clean and free from contaminants. This, in turn, reduces wear on engine components, enhancing the engine’s reliability and extending its operational lifespan.

Installation and Integration

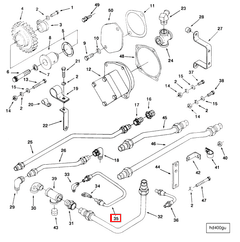

Installing the Scavenge Outlet Tube requires careful consideration of the engine’s design and the tube’s positioning within the lubrication system. Proper installation ensures that the tube functions effectively, facilitating the removal of contaminants and maintaining the efficiency of the lubrication system. It may be necessary to make modifications to the engine’s design to accommodate the tube, ensuring that it is securely and correctly installed.

Maintenance and Troubleshooting

Routine maintenance of the Scavenge Outlet Tube is crucial to ensure its continued effective operation. This includes regular inspections for signs of wear or damage, and cleaning or replacing the tube as necessary. Common issues that may arise include blockages within the tube, which can impede the scavenging process. Troubleshooting these issues typically involves inspecting the tube for obstructions and clearing them to restore efficient operation.

Compatibility and Applications

The Scavenge Outlet Tube is designed for use in a variety of heavy-duty truck engines, demonstrating its versatility and widespread application. Its compatibility with different engine models underscores its importance in the maintenance and efficiency of truck engines across the industry.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the automotive industry, particularly for its heavy-duty truck components. The company’s commitment to excellence is reflected in its product range, which includes a variety of components designed to enhance the performance, efficiency, and reliability of heavy-duty engines.

Cummins Scavenge Outlet Tube Part 3626619

The Cummins Scavenge Outlet Tube part number 3626619 is a critical component in the engine’s air intake system. This part is designed to facilitate the movement of air from the turbocharger to the engine’s intake manifold. It ensures that the air is efficiently directed into the combustion chamber, which is essential for optimal engine performance.

Application in Cummins Engines

The Scavenge Outlet Tube part 3626619 is compatible with several Cummins engine models. Here are some of the engines where this part is used:

-

K19 Series Engines

- The K19 series engines are known for their robust design and reliability. The Scavenge Outlet Tube in these engines ensures that the air intake is smooth and uninterrupted, contributing to the engine’s overall efficiency and power output.

-

Other Cummins Engines

- While the K19 series is a notable application, the Scavenge Outlet Tube part 3626619 is also used in other Cummins engines. Its design allows it to fit seamlessly into various engine configurations, ensuring that the air intake system functions as intended.

Importance in Engine Performance

The Scavenge Outlet Tube plays a pivotal role in the engine’s performance. By directing the air efficiently, it helps in maintaining the right air-fuel mixture, which is crucial for combustion. This part is engineered to withstand the high temperatures and pressures within the engine, ensuring durability and longevity.

Compatibility and Fitment

When it comes to compatibility, the Scavenge Outlet Tube part 3626619 is designed to fit specific engine models. It is essential to verify the part number and engine specifications to ensure a proper fit. This ensures that the engine operates at peak efficiency and prevents any potential air intake issues.

Role of Part 3626619 Scavenge Outlet Tube in Engine Systems

The Scavenge Outlet Tube, identified by part number 3626619, is an integral component in the efficient operation of engine systems, particularly in the context of lubricating oil management and scavenge plumbing.

Lubricating Oil Scavenge Pump Integration

In engine systems equipped with a lubricating oil scavenge pump, the Scavenge Outlet Tube plays a significant role. This tube is responsible for directing the flow of oil from the sump or oil pan back to the pump. The efficient routing of oil ensures that the pump can maintain a consistent supply, which is essential for the continuous lubrication of engine components. This, in turn, helps in reducing friction and wear, contributing to the overall longevity and performance of the engine.

Scavenge Plumbing Functionality

Within the scavenge plumbing system, the Scavenge Outlet Tube serves as a vital conduit. It facilitates the removal of unwanted substances, such as air, fuel, or contaminants, from the engine’s lubrication system. By efficiently channeling these elements away, the tube aids in maintaining the purity and effectiveness of the lubricating oil. This is particularly important in high-performance or high-stress engine environments where the quality of the lubricating oil can significantly impact engine reliability and efficiency.

The Scavenge Outlet Tube’s design and placement within the scavenge plumbing also contribute to the system’s ability to handle varying operational conditions. Whether the engine is under load or idling, the tube ensures that the scavenge process remains effective, thereby supporting the engine’s operational stability and performance.

Conclusion

The Scavenge Outlet Tube, part number 3626619, is a critical component in the maintenance and efficiency of heavy-duty truck engines. Its role in the scavenging process ensures that the engine’s lubrication system remains clean and free from contaminants, thereby enhancing engine performance and reliability. Proper installation, maintenance, and understanding of its function are essential for maximizing the benefits of this Cummins part.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.