3630840

Tube Connector

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3630840 Tube Connector is a critical component in commercial truck systems, designed to enhance the efficiency and reliability of fluid transfer mechanisms. Understanding its purpose and significance is essential for maintaining and optimizing truck performance.

Basic Concepts of Tube Connectors

Tube connectors are essential for joining sections of tubing or piping in fluid systems, facilitating the transfer of liquids or gases. They ensure secure and leak-free connections, maintaining the integrity of fluid pathways crucial for various operational functions in trucks.

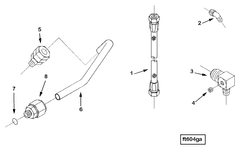

Purpose of the 3630840 Tube Connector

The Cummins 3630840 Tube Connector is designed to connect tubes within commercial trucks’ fluid transfer systems. It ensures a consistent and reliable flow of fluids, including coolant, fuel, or hydraulic fluid, contributing to the seamless operation of the truck.

Key Features

This Cummins part features durable materials that resist corrosion and wear, ensuring longevity in demanding environments. Its design includes precise threading and sealing mechanisms to prevent leaks and maintain secure connections. Additional features may include anti-vibration properties or easy-to-use coupling mechanisms for simplified installation and maintenance.

Benefits

Utilizing the 3630840 Tube Connector offers several advantages, including robust construction that enhances the durability of the fluid transfer system, reducing failures and leaks. Its efficient design ensures optimal fluid flow, improving the truck’s overall performance. Furthermore, its compatibility with various system components allows for versatile application across different truck models and systems.

Installation Process

Installing the 3630840 requires careful attention to detail to ensure a secure fit. The process involves cleaning the connection points, applying necessary sealants, and using appropriate tools to tighten the connector without over-torquing. Following the manufacturer’s guidelines for installation is recommended to achieve the best results and ensure the connector functions as intended.

Maintenance Tips

Regular maintenance of the 3630840 is essential for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or corrosion, cleaning the connector and surrounding areas to prevent buildup, and checking the tightness of the connection to prevent leaks. Adhering to these maintenance practices helps maintain the efficiency of the fluid transfer system.

Troubleshooting Common Issues

Common issues with tube connectors, such as leaks or corrosion, can often be traced back to installation errors or environmental factors. Diagnosing these problems involves inspecting the connector for physical damage, checking the tightness of the connection, and assessing the condition of the surrounding tubing. Resolution may involve tightening the connection, replacing damaged components, or applying corrosion-resistant coatings.

Compatibility and Usage

The 3630840 is designed for use in various truck models and systems, offering versatility in application. Ensuring compatibility involves checking the connector’s specifications against the requirements of the specific truck model and fluid system. This compatibility ensures that the connector functions effectively within the intended system, contributing to the truck’s overall performance.

Safety Considerations

When working with the 3630840, observing safety practices is paramount. This includes wearing appropriate personal protective equipment, ensuring the truck’s engine is off and cooled before beginning work, and following all manufacturer guidelines for handling and installation. Adhering to these safety considerations helps prevent accidents and ensures a secure working environment.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s extensive product range and focus on customer satisfaction underscore its position as a leader in the field.

Tube Connector 3630840 Compatibility with Cummins Engines

The Tube Connector part number 3630840, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines, including the K38 and K50 models. This part plays a role in the engine’s cooling system by ensuring efficient fluid flow and maintaining optimal operating temperatures 1.

K38 and K50 Engines

For the K38 and K50 engines, the Tube Connector 3630840 is engineered to integrate smoothly into the engine’s design. This part is involved in connecting various coolant passages, ensuring that the engine operates efficiently and reliably. The connector’s precise fit and robust construction are important for maintaining the integrity of the cooling system, which is vital for the longevity and performance of these engines 2.

The Tube Connector 3630840 is meticulously designed to meet the specific requirements of the K38 and K50 engines, ensuring compatibility and performance. Its design allows for easy installation and maintenance, making it a preferred choice for technicians and engineers working with these engines.

Role of Part 3630840 Tube Connector in Engine Systems

The 3630840 Tube Connector is a component in the fuel supply plumbing of engine systems. It facilitates the secure and efficient connection between various segments of fuel tubing, ensuring a continuous and reliable flow of fuel from the fuel tank to the engine.

In the context of fuel supply plumbing, the Tube Connector plays a role by:

- Sealing Connections: It creates a tight seal between different sections of fuel tubing, preventing fuel leaks that could lead to dangerous situations.

- Flexibility: Allowing for some degree of movement and flexibility in the fuel lines, which is important given the vibrations and movements an engine undergoes during operation.

- Ease of Maintenance: Facilitating easier disconnection and reconnection of fuel lines during maintenance or repairs, which can save time and reduce the complexity of service procedures.

- Compatibility: Designed to be compatible with various types of fuel tubing materials, ensuring it can be used in a wide range of engine systems without the need for additional adapters or modifications.

- Pressure Regulation: Helping maintain consistent pressure within the fuel lines, which is vital for the proper functioning of fuel injectors and carburetors.

Overall, the 3630840 Tube Connector is an element in the fuel supply system, contributing to the safety, efficiency, and reliability of engine operations 3.

Conclusion

The Cummins 3630840 Tube Connector is a vital component in commercial truck systems, ensuring efficient and reliable fluid transfer. Its durable construction, precise design, and compatibility with various systems make it an essential part for maintaining the performance and safety of trucks. Regular maintenance and adherence to safety practices are crucial for maximizing the benefits of this connector.

-

Heavyduty Electric Vehicles: From Concept to Reality, Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Elsevier, 2021.

↩ -

Generalized Vehicle Dynamics, Daniel Williams, SAE International, 2022.

↩ -

Gasoline Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.