This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

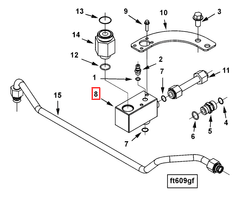

The 3637123 Tube Connector, manufactured by Cummins, is a component designed for use in commercial trucks. This part facilitates the secure transfer of fluids within the truck’s systems. Cummins is a well-established manufacturer in the automotive industry, known for its commitment to quality and innovation in producing reliable automotive components 1.

Basic Concepts of Tube Connectors

Tube connectors are devices used in fluid systems to join tubes or pipes, allowing for the transfer of liquids or gases. They are integral in maintaining the integrity of fluid systems by providing secure and leak-free connections. The effectiveness of a tube connector in preventing leaks and ensuring a stable connection is vital for the efficient operation of any fluid system 2.

Purpose of the 3637123 Tube Connector

The 3637123 Tube Connector is specifically designed to connect various fluid systems within a truck. It facilitates the transfer of fluids such as coolant, fuel, or hydraulic fluid, contributing to the overall functionality and efficiency of the truck’s systems. By ensuring a secure connection, it plays a role in maintaining the performance and reliability of these systems 3.

Key Features

This Cummins part boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. Its design includes precision-machined fittings that allow for a snug fit, reducing the risk of leaks. Additionally, it features a robust construction that can withstand the high pressures and temperatures often encountered in commercial truck applications 4.

Benefits

Using the 3637123 Tube Connector offers several advantages. Its reliable design contributes to improved system performance and reduced maintenance needs. The ease of installation and compatibility with various systems make it a practical choice for truck maintenance and repair. Furthermore, its durable construction ensures long-term use, supporting the overall longevity and efficiency of the truck.

Installation Process

Installing this part requires careful attention to detail to ensure a secure and efficient connection. The process involves cleaning the connection points, applying the appropriate sealant if necessary, and then connecting the tube to the fitting. It is important to follow the manufacturer’s guidelines to achieve the best results and ensure the connector functions as intended.

Troubleshooting Common Issues

Common issues with tube connectors may include leaks, improper fitting, or damage to the connector. Troubleshooting these problems involves inspecting the connection for signs of wear or damage, ensuring the correct sealant has been used, and verifying that the connector is properly aligned and tightened. Addressing these issues promptly can help maintain the efficiency and safety of the truck’s fluid systems.

Maintenance Tips

Regular maintenance of the 3637123 Tube Connector is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear, corrosion, or leaks. Cleaning the connector and its surrounding areas can prevent buildup that may affect its function. Additionally, following the manufacturer’s recommendations for maintenance can help avoid common issues and ensure the connector remains in good working condition.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the automotive industry, with a history of producing high-quality components for commercial vehicles. The company is recognized for its commitment to innovation, quality, and customer satisfaction. Cummins’ reputation is built on its ability to deliver reliable and efficient solutions for the automotive sector, making it a trusted name among professionals in the industry.

Role of 3637123 Tube Connector in Engine Systems

The 3637123 Tube Connector is an essential component in the fuel plumbing system of various engine setups. Its primary function is to facilitate the secure and efficient connection of fuel lines, ensuring a consistent and reliable fuel supply to the engine.

Integration with Fuel Plumbing

In the fuel plumbing system, the Tube Connector serves as a junction point where multiple fuel lines converge or diverge. This is particularly important in systems where fuel needs to be distributed to different parts of the engine or where return lines are integrated back into the supply system. The connector ensures that there are no leaks at these junction points, maintaining the integrity of the fuel system.

Use in Tube Connector Tee Configurations

When configured as a Tube Connector Tee, 3637123 allows for the branching of fuel lines. This setup is commonly used to supply fuel to multiple injectors or carburetors simultaneously. The Tee configuration ensures that each branch receives an equal and consistent flow of fuel, which is vital for the balanced operation of the engine.

The Tube Connector also plays a role in managing fuel pressure within the system. By providing a stable connection point, it helps in maintaining consistent pressure levels, which is essential for the proper atomization of fuel in the combustion chamber. This, in turn, contributes to more efficient fuel combustion and overall engine performance.

Conclusion

In summary, the 3637123 Tube Connector is a fundamental component in the fuel delivery system, ensuring secure connections, efficient fuel distribution, and consistent fuel pressure, all of which are vital for the optimal operation of engine systems.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.