This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

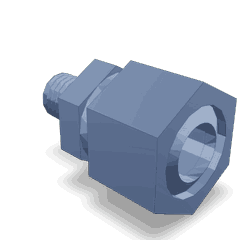

The Cummins 3655143 Tube Connector is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s fluid systems, contributing to the overall efficiency and reliability of the truck’s operations. Understanding its purpose and significance can help in maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts of Tube Connectors

Tube connectors are components used in fluid systems to join different sections of tubing or piping. They facilitate the transfer of fluids such as fuel, coolant, or hydraulic fluid throughout the system. In the context of heavy-duty trucks, these connectors ensure that fluid lines are securely and efficiently connected, allowing for the proper functioning of various systems within the vehicle 1.

Purpose of the Cummins 3655143 Tube Connector

The Cummins 3655143 Tube Connector is designed to connect and secure fluid lines within a truck’s system. It plays a role in maintaining the integrity of the fluid pathways, ensuring that fluids are transported without leaks or interruptions. This connector is integral to the operation of the truck’s fluid systems, contributing to the overall performance and reliability of the vehicle 2.

Key Features

The Cummins 3655143 Tube Connector is constructed from durable materials, ensuring it can withstand the rigors of heavy-duty truck operations. Its design includes features that enhance its performance and durability, such as a secure locking mechanism to prevent disconnections and a corrosion-resistant coating to prolong its lifespan. These attributes make it a reliable component for use in demanding environments 3.

Benefits

The Cummins 3655143 Tube Connector offers several advantages, including improved reliability due to its robust construction and design. It also features ease of installation, allowing for quick and efficient replacement or upgrade of fluid lines. Additionally, its maintenance benefits include reduced need for frequent replacements, contributing to lower overall maintenance costs for truck operators 4.

Installation Process

Installing the Cummins 3655143 Tube Connector involves several steps to ensure a secure and proper connection. First, the appropriate fluid lines are prepared for connection. The connector is then aligned with the lines and secured in place using the provided locking mechanism. Tools such as wrenches may be required to tighten connections, ensuring they are snug and leak-free 5.

Troubleshooting Common Issues

Common issues with tube connectors, such as leaks or improper connections, can often be traced back to installation errors or wear and tear. Troubleshooting these problems involves checking the connections for tightness, inspecting the connector for signs of damage or corrosion, and ensuring that the fluid lines are correctly aligned and free from obstructions 6.

Maintenance Tips

Regular maintenance of the Cummins 3655143 Tube Connector includes periodic inspection for signs of wear, corrosion, or damage. Cleaning the connector and its surrounding areas can prevent buildup that may lead to leaks or blockages. Additionally, ensuring that all connections are tight and secure during routine checks can help maintain the integrity of the fluid system 7.

Safety Considerations

When working with tube connectors, it is important to observe safety guidelines to prevent accidents or injuries. This includes wearing appropriate personal protective equipment, ensuring that the truck’s engine is off and cooled down before beginning work, and following manufacturer recommendations for installation and maintenance procedures 8.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. Their product range includes engines, filtration systems, and components like the Cummins 3655143 Tube Connector, all designed to meet the demanding requirements of commercial and industrial applications 9.

Tube Connector 3655143 Compatibility with Cummins Engines

The Tube Connector part number 3655143, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This part is integral in ensuring the proper functioning of the engine’s cooling system by facilitating the connection between different tubes and hoses.

K38 Series Engines

The Tube Connector 3655143 is specifically engineered to integrate with the K38 series engines. These engines are known for their robust performance and reliability, making them a popular choice in various industrial applications. The connector’s design ensures a secure and leak-free connection, which is crucial for maintaining optimal engine performance and longevity 10.

Group Compatibility

In addition to the K38 series, the Tube Connector 3655143 is also compatible with other Cummins engine groups where similar design specifications are met. This includes engines that share common architectural features and cooling system requirements. The compatibility extends to engines that have been designed to work within the same operational parameters, ensuring that the connector fits snugly and functions as intended 11.

Installation and Usage

When installing the Tube Connector 3655143, it is essential to follow the manufacturer’s guidelines to ensure a proper fit and function. The connector should be installed in a way that maintains the integrity of the cooling system, preventing any potential leaks or performance issues. Regular maintenance checks should be performed to ensure the connector remains in good condition and continues to perform its intended function effectively 12.

Role of Part 3655143 Tube Connector in Engine Systems

Part 3655143 Tube Connector is integral to the efficient operation of both plumbing and fuel supply systems within engine environments. In plumbing systems, this component ensures secure and leak-proof connections between various pipes and fittings, facilitating the smooth transfer of fluids. Its design allows for easy installation and removal, which is essential during maintenance or upgrades.

In fuel systems, the Tube Connector plays a significant role in maintaining the integrity of the fuel lines. It ensures that fuel is delivered consistently and without leaks to the engine components, which is vital for optimal engine performance. The connector’s robust construction withstands the pressures and temperatures associated with fuel transport, contributing to the reliability of the fuel supply system.

Additionally, the Tube Connector is often used in conjunction with filters and regulators within these systems. In plumbing, it connects to water filters and pressure regulators, ensuring that the water delivered is clean and at the correct pressure. In fuel systems, it links to fuel filters and pressure regulators, which are necessary for removing impurities and maintaining the correct fuel pressure for combustion.

The Tube Connector also interfaces with various sensors and monitoring devices. In plumbing systems, it may connect to flow meters or pressure sensors, allowing for real-time monitoring of system performance. In fuel systems, it can be linked to fuel level sensors or pressure transducers, providing essential data for engine management systems.

Overall, Part 3655143 Tube Connector is a versatile and reliable component that enhances the functionality and safety of both plumbing and fuel supply systems in engine applications 13.

Conclusion

The Cummins 3655143 Tube Connector is a critical component in the fluid systems of heavy-duty trucks, ensuring secure and efficient connections that contribute to the vehicle’s overall performance and reliability. Its robust construction, ease of installation, and maintenance benefits make it a valuable asset for truck operators. Regular maintenance and adherence to safety guidelines are essential for maximizing the lifespan and effectiveness of this part.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ -

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 2883368.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ -

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 2883368.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ -

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.