This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

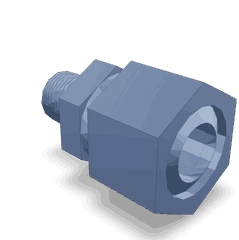

The Cummins 3655144 Tube Connector is a component designed for use in commercial trucks. It serves a specific function within the truck’s fluid systems, contributing to the overall operation and efficiency of the vehicle. Cummins, a well-regarded manufacturer in the automotive industry, produces this connector as part of their range of high-quality automotive components 1.

Basic Concepts of Tube Connectors

Tube connectors are devices used to join tubes or pipes in fluid systems. Their primary function is to create secure and leak-free connections, which is vital for the efficient operation of these systems. Tube connectors come in various designs and materials, each suited to specific applications based on the type of fluid being transported and the operating conditions 2.

Purpose of the 3655144 Tube Connector

This Cummins part is designed to facilitate the connection between different sections of tubing within a truck’s fluid system. It plays a role in ensuring that fluids are transported securely and efficiently throughout the system. This connector is part of the infrastructure that supports the truck’s operation, handling fluids that are integral to the vehicle’s performance 3.

Key Features

The 3655144 is constructed from materials that offer durability and resistance to the fluids it handles. Its design includes features that enhance its performance, such as precise fitting mechanisms that ensure a tight seal. These attributes contribute to the connector’s reliability and longevity in demanding commercial truck environments.

Benefits

Using this Cummins part offers several advantages, including improved system reliability due to its secure connection capabilities. It is designed for ease of installation, which can reduce downtime during maintenance procedures. Additionally, its construction allows for straightforward maintenance, contributing to the overall performance and efficiency of the truck.

Installation Process

Installing the 3655144 requires following a series of steps to ensure a proper fit and secure connection. Best practices include verifying the compatibility of the connector with the tubing and system it will join, using the appropriate tools for installation, and checking for a leak-free seal upon completion. Detailed instructions should be consulted for specific guidance.

Troubleshooting and Maintenance

Common issues with tube connectors may include leaks or difficulties in installation. Troubleshooting steps can involve checking the seal integrity, ensuring correct alignment during installation, and verifying that the connector is compatible with the system. Regular maintenance, such as inspecting for wear and ensuring connections remain tight, can help maintain the connector’s performance.

Compatibility and Application

The 3655144 is designed for use in specific types of commercial trucks and fluid systems. Its application is tailored to meet the demands of these environments, ensuring compatibility with various truck models and configurations. Understanding the connector’s intended use can help in selecting the appropriate component for a given system.

Safety Considerations

When installing or maintaining the 3655144, it is important to observe safety guidelines to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring the system is depressurized before working on it, and following manufacturer recommendations for installation and maintenance. Awareness of potential hazards and taking steps to mitigate them are crucial for safe operation.

Cummins Overview

Cummins is a manufacturer with a strong reputation in the automotive industry, known for its commitment to quality and innovation. The company has a history of producing reliable components that contribute to the performance and efficiency of commercial vehicles. Their range of products, including the 3655144, reflects their dedication to meeting the needs of their customers with high-quality solutions.

Compatibility with Cummins Engines

This part is designed to integrate seamlessly with a variety of Cummins engine models. It is crucial for maintaining the integrity of the engine’s cooling system by ensuring proper fluid flow and preventing leaks.

K38 Engine Series

The K38 engine series is one of the many engine families where the 3655144 is utilized. This series is known for its robust design and efficiency, making it a popular choice in various industrial applications. The Tube Connector in this series ensures that the coolant flows efficiently through the engine, maintaining optimal operating temperatures and preventing overheating.

Grouping of Compatible Engines

While the 3655144 is specifically designed for the K38 engine series, it is also compatible with other Cummins engines that share similar design characteristics and cooling system requirements. These engines often include:

- K19 Series: Known for its reliability and performance, the K19 series benefits from the precise fit and durability of the 3655144.

- QSK Series: The QSK series, which includes high-power output engines, also utilizes this tube connector to ensure efficient coolant management.

- QSL Series: The QSL series, designed for heavy-duty applications, relies on the 3655144 to maintain its cooling system’s efficiency.

By ensuring a proper fit and function, the 3655144 helps maintain the performance and longevity of these engines, making it an essential component for Cummins engine owners and technicians.

Role of the 3655144 in Engine Systems

The 3655144 is an essential component in the integration and functionality of various engine systems, particularly in the realms of plumbing and fuel supply.

In plumbing systems, the 3655144 facilitates the secure and leak-proof joining of pipes and hoses. This ensures that fluids, whether they be coolants, lubricants, or other necessary liquids, are efficiently transported throughout the engine system without any loss or contamination. The connector’s design allows for easy installation and removal, which is vital during maintenance or repair procedures.

Within the fuel system, the 3655144 plays a significant role in maintaining the integrity of the fuel lines. It ensures that fuel is delivered consistently and under the correct pressure to the engine’s combustion chambers. This is achieved by creating a robust seal that prevents fuel leaks, which could otherwise lead to dangerous situations or inefficient engine performance.

Additionally, the connector is designed to withstand the high pressures and temperatures often encountered in fuel systems, ensuring reliable operation under various engine conditions. Its application in fuel supply lines also contributes to the overall safety and efficiency of the engine, as it helps in preventing fuel system failures that could arise from loose or damaged connections.

Conclusion

In summary, the 3655144 is a fundamental component that enhances the reliability and performance of both plumbing and fuel systems in engine applications. Its role in ensuring secure and efficient fluid transport is critical for the operation and maintenance of commercial trucks and engines.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Bennett, S., & Norman, I.A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.