This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3686395 Pressure Sensing Tube is a component designed for use in heavy-duty trucks. It serves a specific function within the truck’s system, contributing to the overall operation and performance of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Pressure Sensing Tubes

A pressure sensing tube is a component that facilitates the measurement and monitoring of pressure within a system. In the context of heavy-duty trucks, these tubes are integral to various subsystems, allowing for the accurate detection of pressure changes. The principles of pressure sensing technology involve the conversion of physical pressure into an electrical signal, which can then be interpreted by the truck’s electronic control systems 1.

Purpose of the Cummins 3686395 Pressure Sensing Tube

The Cummins 3686395 Pressure Sensing Tube plays a role in the truck’s system by providing accurate pressure readings. This information is vital for the proper functioning of the engine and other systems, as it allows for adjustments and interventions based on real-time data. Its integration with other systems ensures that the truck operates efficiently and reliably under various conditions.

Key Features

The Cummins 3686395 Pressure Sensing Tube is characterized by several key features. Its material composition is designed to withstand the harsh environments typical of heavy-duty truck operations. The design elements of the tube, including its length and diameter, are tailored to fit specific applications within the truck’s system. Technological advancements incorporated into the tube enhance its durability and accuracy.

Benefits

The advantages provided by the Cummins 3686395 Pressure Sensing Tube include improved performance, reliability, and efficiency in truck operations. By ensuring accurate pressure readings, the tube contributes to the optimal functioning of the engine and other systems. This leads to enhanced overall performance and longevity of the truck.

Installation and Integration

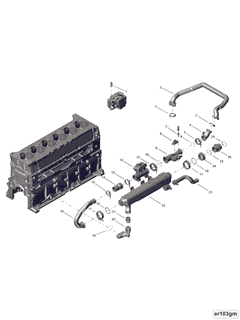

Installing the Cummins 3686395 Pressure Sensing Tube involves several steps and considerations. Compatibility with various truck models and systems is a key factor to ensure proper integration. Following manufacturer guidelines during installation is important to maintain the tube’s functionality and the truck’s performance.

Troubleshooting Common Issues

Common problems associated with pressure sensing tubes can include inaccurate readings or physical damage to the tube. Potential causes may range from environmental factors to mechanical issues within the truck’s system. Recommended troubleshooting steps involve checking the tube for physical damage, ensuring proper installation, and verifying the accuracy of the readings against known standards.

Maintenance Tips

Maintaining the Cummins 3686395 Pressure Sensing Tube is important to ensure its longevity and optimal performance. Regular checks for physical damage and ensuring the tube is securely installed are fundamental maintenance practices. Additionally, keeping the tube clean and free from debris contributes to its accurate functioning.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. Its product range includes engines and components for heavy-duty trucks, among other applications, reflecting a commitment to enhancing performance and reliability across various sectors 2.

Role of Part 3686395 Pressure Sensing Tube in Engine Systems

The Part 3686395 Pressure Sensing Tube is an integral component in the operation of Exhaust Recirculation (EGR) systems. It is designed to accurately measure the pressure within the EGR system, which is essential for the proper functioning of the engine.

In the EGR system, the Pressure Sensing Tube is connected to the EGR valve and the EGR cooler. Its primary function is to monitor the pressure differential between the intake manifold and the exhaust manifold. This data is then relayed to the Engine Control Unit (ECU), which uses it to adjust the operation of the EGR valve.

The EGR valve, when commanded by the ECU, allows a measured amount of exhaust gas to be recirculated back into the intake manifold. This recirculation helps in reducing nitrogen oxides (NOx) emissions by lowering the combustion temperature within the cylinders.

The Pressure Sensing Tube also interfaces with the EGR pressure sensor, which is responsible for converting the pressure readings into electrical signals. These signals are then transmitted to the ECU, allowing it to make real-time adjustments to the EGR flow.

Additionally, the Pressure Sensing Tube may be connected to other components such as the EGR temperature sensor, which monitors the temperature of the recirculated exhaust gases. This temperature data, combined with pressure readings, enables the ECU to optimize the EGR system’s performance under varying engine loads and operating conditions.

Overall, the Part 3686395 Pressure Sensing Tube plays a significant role in ensuring that the EGR system operates efficiently, contributing to reduced emissions and improved engine performance 3.

Conclusion

The Cummins 3686395 Pressure Sensing Tube is a vital component in heavy-duty trucks, particularly in the ISX15 CM2250 and QSX15 CM2250 ECF engines. Its role in accurately measuring pressure within the system ensures the engines’ optimal performance, contributing to efficient operation and longevity. The tube’s integration into the EGR system further highlights its importance in reducing emissions and enhancing engine reliability. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.