This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

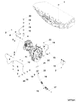

The Tur Coolant Drain Tube, identified by part number 3697151 and manufactured by Cummins, is a critical component for the maintenance of heavy-duty trucks. This Cummins part is designed to facilitate the efficient drainage of coolant from the engine cooling system, ensuring the upkeep and performance of commercial trucks. Cummins, a leader in diesel engine manufacturing, ensures that this component meets the rigorous demands of heavy-duty applications.

Basic Concepts and Functionality

Coolant drain tubes in heavy-duty trucks serve the fundamental purpose of allowing coolant to be efficiently removed from the engine cooling system. The Tur Coolant Drain Tube operates by providing a pathway for coolant to exit the system, which is essential during maintenance procedures such as coolant changes or system flushes. It interacts with other components of the cooling system, ensuring that coolant can be drained without causing damage or leaving residual coolant that could lead to inefficiencies or corrosion 1.

Purpose of the Tur Coolant Drain Tube

The Tur Coolant Drain Tube plays a role in the operation of a truck by enabling the efficient drainage of coolant. This process is vital for maintaining the engine’s performance and longevity. By allowing for complete coolant removal, the tube helps prevent the buildup of contaminants and old coolant, which can degrade engine efficiency and lead to corrosion. Efficient coolant drainage contributes to the overall health of the engine, ensuring it operates within optimal temperature ranges and maintains its durability over time 2.

Key Features

The design and construction of the Tur Coolant Drain Tube are tailored to meet the demands of heavy-duty truck applications. Crafted from durable materials, the tube is built to withstand the pressures and temperatures of the engine cooling system. Its construction ensures reliability and longevity, with features that enhance its performance and ease of use during maintenance procedures. The tube’s design also considers the need for compatibility with various truck models and engine types, ensuring a seamless integration into existing systems.

Benefits

The Tur Coolant Drain Tube offers several advantages that contribute to the efficiency and maintenance of the coolant system. Improved coolant system efficiency is achieved through the tube’s ability to facilitate complete drainage, reducing the risk of contamination and ensuring that fresh coolant can circulate effectively. Ease of maintenance is another benefit, as the tube’s design allows for straightforward coolant changes and system flushes. These advantages translate to operational benefits for truck drivers and fleet operators, including enhanced engine performance, reduced downtime, and lower maintenance costs 3.

Installation and Compatibility

Proper installation of the Tur Coolant Drain Tube is crucial for ensuring its effectiveness and the integrity of the cooling system. Guidelines for installation should be followed to integrate the tube into the existing cooling system without causing leaks or inefficiencies. Compatibility with specific truck models and engine types must be ensured to avoid issues with fitment or function. Tips for installation may include checking for proper alignment, securing connections, and verifying that the tube does not interfere with other components.

Troubleshooting and Maintenance

Common issues associated with coolant drain tubes can include leaks, blockages, or damage to the tube itself. Symptoms of these issues may include coolant loss, overheating, or inefficient coolant drainage. A step-by-step troubleshooting guide can help identify and resolve these problems, ensuring the tube continues to function correctly. Maintenance tips for the Tur Coolant Drain Tube include regular inspection for signs of wear or damage, ensuring connections are secure, and following manufacturer recommendations for coolant changes and system flushes.

Safety Considerations

When working with the Tur Coolant Drain Tube, it is important to observe safety practices to protect both the individual and the vehicle. Precautions during installation, maintenance, and troubleshooting should include wearing appropriate personal protective equipment, ensuring the engine is cool before beginning work, and following all manufacturer guidelines for handling and installation. These safety measures help prevent personal injury and damage to the vehicle, ensuring a safe working environment.

Cummins: A Brief Overview

Cummins Inc. is a leader in the diesel engine manufacturing industry, with a history of innovation and commitment to quality. The company’s expertise in engine technology and components extends to the automotive industry, where it provides reliable and high-quality parts for commercial trucks. Cummins’ dedication to innovation and customer satisfaction ensures that its components, like the Tur Coolant Drain Tube, meet the high standards required for heavy-duty applications.

Conclusion

The Tur Coolant Drain Tube, part number 3697151, is a vital component in the maintenance and operation of heavy-duty trucks. Its role in facilitating efficient coolant drainage contributes to the overall health and performance of the engine. With its durable construction, ease of maintenance, and compatibility with various truck models, this Cummins part ensures that commercial trucks operate efficiently and reliably. Proper installation, regular maintenance, and adherence to safety practices are essential for maximizing the benefits of this component.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.