This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

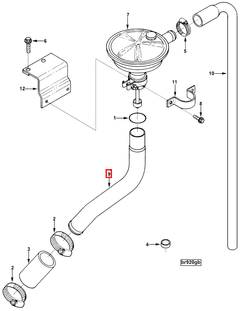

The Cummins 3921350 Breather Tube is a critical component designed for use in commercial trucks. Its primary function is to facilitate the release of pressure and contaminants from the engine’s crankcase, contributing to the overall efficiency and longevity of the vehicle’s engine. Understanding its function and significance is essential for maintaining optimal truck performance.

Basic Concepts of Breather Tubes

Breather tubes are essential components in automotive applications that allow for the release of pressure and contaminants from various systems, such as the engine’s crankcase. They play a crucial role in maintaining the efficiency and safety of the vehicle by ensuring that excess pressure does not build up, which could lead to engine damage. Additionally, they help in expelling contaminants that could otherwise circulate within the engine, potentially causing wear and reducing performance 1.

Purpose of the Cummins 3921350 Breather Tube

The Cummins 3921350 Breather Tube is specifically designed to serve within the engine system of a truck. It functions by allowing the release of pressure and contaminants from the crankcase, which helps in maintaining a clean and pressurized environment within the engine. This contributes to the engine’s overall performance and durability by preventing the buildup of harmful substances and ensuring that the engine operates under optimal conditions 2.

Key Features

The Cummins 3921350 Breather Tube is constructed with high-quality materials to ensure durability and reliability. Its design includes features that enhance its functionality, such as a robust build that can withstand the harsh conditions of commercial truck operations. The tube is engineered to provide a secure fit and efficient operation, with unique characteristics that differentiate it from other breather tubes in the market.

Benefits

The use of the Cummins 3921350 Breather Tube offers several advantages. It contributes to improved engine performance by maintaining a clean crankcase environment. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. Additionally, by enhancing engine efficiency and longevity, it can lead to potential cost savings for fleet operators through reduced maintenance and repair expenses 3.

Installation and Compatibility

Proper installation of the Cummins 3921350 Breather Tube is crucial for ensuring its effective operation. It is designed to be compatible with specific truck models and engine types, ensuring a seamless integration into the vehicle’s system. Following the manufacturer’s guidelines for installation is recommended to achieve the best performance and longevity from the component.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3921350 Breather Tube is important for ensuring its optimal performance. This includes periodic checks for signs of wear or damage and ensuring that it remains securely fitted. Common issues that may arise include blockages or leaks, which can be addressed through cleaning or replacement as necessary. Adhering to a maintenance schedule can help in identifying and resolving issues before they lead to more significant problems.

Safety Considerations

When working with the Cummins 3921350 Breather Tube, it is important to observe safety guidelines and precautions. This includes ensuring that the engine is cool before beginning any maintenance or installation procedures. Proper handling and secure fitting of the tube are also important to prevent accidents or damage to the component. Following these safety considerations helps in maintaining a safe working environment.

Environmental Impact

The use of the Cummins 3921350 Breather Tube, like any automotive component, has environmental considerations. Cummins Inc. is committed to minimizing the ecological footprint of their products through various initiatives, including the use of sustainable materials and manufacturing processes where possible. Understanding and adhering to proper disposal and recycling practices for automotive components also contribute to reducing environmental impact.

Cummins Corporation

Cummins Inc. is a leading manufacturer in the automotive industry, known for its commitment to innovation, quality, and customer satisfaction. With a history of producing reliable and high-performance engine components, Cummins continues to lead the way in technological advancements and environmental stewardship within the industry. Their product offerings span a wide range of applications, catering to the diverse needs of commercial and industrial customers.

Cummins Breather Tube Part 3921350 Compatibility

The Cummins Breather Tube part number 3921350 is designed to fit seamlessly into various engine models, ensuring optimal performance and reliability. This part is integral to the engine’s ventilation system, facilitating the release of air and preventing pressure build-up.

Engine Compatibility

-

6C8.3: The Breather Tube part 3921350 is specifically engineered to fit the 6C8.3 engine. It ensures proper air circulation within the engine’s crankcase, which is crucial for maintaining engine health and efficiency.

-

C8.3 G: Similarly, the 3921350 part is compatible with the C8.3 G engine. This model benefits from the breather tube’s ability to manage air flow, contributing to the engine’s overall performance and longevity.

These engines, while distinct, share common design elements that allow the breather tube to integrate effectively. The part’s design ensures it fits snugly and functions optimally within the specified engine models.

Role of Part 3921350 Breather Tube in Engine Systems

The part 3921350 Breather Tube is an essential component in maintaining the health and efficiency of engine systems by facilitating the breather and crankcase ventilation processes.

In the breather system, the Breather Tube allows for the release of pressure build-up within the engine’s crankcase. As the engine operates, it generates gases and vapors that need to be expelled to prevent excessive pressure, which could lead to leaks or damage. The Breather Tube provides a controlled pathway for these byproducts to escape, ensuring that the engine maintains optimal pressure levels.

Additionally, the Breather Tube plays a significant role in the crankcase ventilation system. The crankcase accumulates blow-by gases—a mixture of air, fuel, and combustion byproducts—that escape past the piston rings. These gases, if not properly ventilated, can contaminate the engine oil and reduce its lubricating efficiency. The Breather Tube directs these gases away from the crankcase, often routing them back into the intake system where they can be re-burned, thus promoting cleaner and more efficient combustion.

By integrating the Breather Tube into these systems, engine designers ensure that the engine operates within safe pressure parameters, maintains clean lubrication, and enhances overall performance and longevity.

Conclusion

The Cummins 3921350 Breather Tube is a vital component for maintaining the efficiency and longevity of commercial truck engines. Its role in facilitating the release of pressure and contaminants from the crankcase is crucial for optimal engine performance. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part. Additionally, understanding its environmental impact and compatibility with specific engine models ensures that fleet operators can make informed decisions for their vehicle maintenance strategies.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.