This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

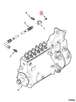

The Cummins 3921556 Tube Cap is a component designed for use in commercial truck fluid systems. Its primary role is to seal and protect the ends of tubes and hoses, ensuring the integrity and efficiency of the fluid conveyance system. A tube cap, in general, serves to prevent leaks, contamination, and damage to the ends of tubes, thereby maintaining the system’s performance and safety 1.

Purpose and Function

The Cummins 3921556 Tube Cap is integral to the fluid systems of commercial trucks. It functions by providing a secure seal at the ends of tubes and hoses, which helps in maintaining the pressure and flow of fluids within the system. This part plays a role in preventing leaks, which could lead to fluid loss and potential system failure. Additionally, it protects the tube ends from environmental contaminants and physical damage, ensuring the longevity and reliability of the fluid system 2.

Key Features

The Cummins 3921556 Tube Cap is constructed with materials and design elements that enhance its performance and durability. It is typically made from high-quality materials that resist corrosion and wear, ensuring long-term reliability. The design of the cap includes features that allow for a tight and secure fit on various tube sizes, providing a consistent seal. Additionally, it may incorporate elements that facilitate easy installation and removal, enhancing its usability in maintenance procedures.

Benefits

Using the Cummins 3921556 Tube Cap offers several advantages. It contributes to improved system integrity by ensuring a secure seal, which prevents leaks and maintains fluid pressure. This leads to enhanced safety, as a well-sealed system reduces the risk of fluid spills and associated hazards. Furthermore, the cap’s durable construction and resistance to wear contribute to the increased longevity of the fluid conveyance system, reducing the need for frequent replacements and maintenance.

Installation and Usage

Proper installation of the Cummins 3921556 Tube Cap is vital for its effectiveness. It should be fitted securely onto the tube or hose end, ensuring a tight seal. Best practices include cleaning the tube end before installation to remove any debris or contaminants that could compromise the seal. Additionally, periodic checks should be conducted to ensure the cap remains securely in place and the seal is intact.

Troubleshooting and Maintenance

Common issues with tube caps include leaks due to improper installation or wear and tear. Troubleshooting involves checking the cap’s fit and condition, ensuring it is correctly installed and not damaged. Maintenance tips include regular inspection of the cap for signs of wear or corrosion, and replacement if necessary, to maintain system integrity and safety.

Compatibility and Applications

The Cummins 3921556 Tube Cap is designed for use in various commercial truck systems, compatible with a range of tubes and hoses. Its applications extend to fuel, hydraulic, and coolant systems, where it plays a role in maintaining the efficiency and safety of fluid conveyance.

Safety Considerations

When installing and maintaining the Cummins 3921556 Tube Cap, it is important to follow safety guidelines. This includes ensuring the system is depressurized before working on it to prevent injuries from fluid spray. Proper handling and storage of the cap are also crucial to maintain its integrity and effectiveness.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation in automotive components. With a history of producing reliable and high-performance parts, Cummins continues to be a trusted name in the industry, dedicated to enhancing the efficiency and safety of commercial vehicles.

Tube Cap 3921556 Compatibility with Cummins Engines

The Tube Cap part number 3921556, manufactured by Cummins, is designed to fit a variety of their engine models. This part is essential for maintaining the integrity of the engine’s cooling system by providing a secure seal for the coolant passages. Below is a detailed breakdown of the engines that are compatible with this tube cap:

Cummins 6B5.9 and 6C8.3 Engines

The Tube Cap 3921556 is compatible with the Cummins 6B5.9 and 6C8.3 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The tube cap ensures that the coolant passages remain sealed, preventing leaks and maintaining optimal engine temperature.

Cummins ISB CM550 and QSB5.9 44 CM550 Engines

The Tube Cap 3921556 is also suitable for the Cummins ISB CM550 and QSB5.9 44 CM550 engines. These engines are part of Cummins’ QSB and ISB series, which are widely recognized for their versatility and efficiency in both industrial and commercial applications. The tube cap’s role in these engines is to maintain the coolant system’s integrity, ensuring consistent performance and longevity.

Cummins L8.9 L121 Engine

The Tube Cap 3921556 fits the Cummins L8.9 L121 engine, which is another model in Cummins’ lineup of heavy-duty engines. This engine is designed for applications that require high power output and durability. The tube cap is crucial in this engine as it helps in maintaining the coolant system’s pressure and preventing any potential leaks.

Cummins QSB5.9 CM2880 B115 and QSB5.9G Engines

The Tube Cap 3921556 is also compatible with the Cummins QSB5.9 CM2880 B115 and QSB5.9G engines. These engines are part of the QSB series, known for their reliability and efficiency. The tube cap ensures that the coolant passages are properly sealed, which is vital for the engine’s cooling system to function correctly.

By ensuring that the Tube Cap 3921556 is correctly installed in these engines, users can maintain the performance and longevity of their Cummins engines, preventing potential issues related to coolant leaks and system failures.

Role of Part 3921556 Tube Cap in Engine Systems

The 3921556 Tube Cap is an essential component in various engine systems, ensuring the integrity and efficiency of fuel and oil pathways. Its applications span across several key components, contributing to the overall performance and reliability of the engine.

Fuel System Integration

In the Base Fuel Pump and Fuel Pump systems, the 3921556 Tube Cap seals connections, preventing leaks and maintaining pressure within the fuel lines. This is particularly important in the Fuel Pump Coupling and Fuel Pump Conv. Kit, where secure fittings are necessary to ensure consistent fuel delivery to the engine.

For the Bosch Injection Pump and Fuel Injection Pump, the Tube Cap plays a role in sealing oil supply lines, ensuring that the pump receives a steady flow of lubrication. This is vital for the pump’s longevity and efficient operation.

Engine Block and Cylinder Applications

Within the Block and Cylinder Block, the 3921556 Tube Cap is used in the Injection Pump Oil Supply system. It ensures that oil lines are properly sealed, facilitating the smooth operation of the injection pump and contributing to the engine’s overall efficiency.

Compressor and Air Systems

In Compressor and Air systems, the Tube Cap is employed to seal connections in the Plumbing and Front Gear Train Accessory systems. This ensures that air pathways remain intact, supporting the compressor’s function in providing pressurized air for various engine components.

Additional System Applications

The Tube Cap is also integral in the Panel Engine Instrument systems, where it seals fuel and oil lines leading to instruments, ensuring accurate readings and reliable performance. In the Mounting Fuel Pump and Pump Fuel systems, it secures connections, maintaining the structural integrity of the fuel pump assembly.

Furthermore, in the Plumbing Fuel Pump Lubrication system, the Tube Cap ensures that lubrication lines are sealed, supporting the smooth operation of the fuel pump. It also plays a role in the Pump Fuel Injection system, where secure fittings are essential for precise fuel delivery.

Specialized Applications

In the Latchout Oil Press system, the 3921556 Tube Cap seals oil pressure lines, ensuring that the system operates within specified parameters. This is particularly important for maintaining engine health and performance under varying operating conditions.

Overall, the 3921556 Tube Cap is a versatile component that enhances the functionality and reliability of various engine systems by ensuring secure and leak-free connections.

Conclusion

The Cummins 3921556 Tube Cap is a critical component in maintaining the integrity and efficiency of commercial truck fluid systems. Its role in sealing and protecting tube and hose ends is essential for preventing leaks, contamination, and damage. The part’s durable construction and compatibility with various Cummins engines make it a reliable choice for ensuring the longevity and safety of fluid conveyance systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.