This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

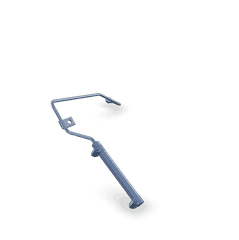

The Cummins 3938926 Pressure Sensing Tube is a component designed for use in commercial trucks. It serves a specific function within the truck’s system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Pressure Sensing Tubes

A Pressure Sensing Tube is a component used to monitor and regulate pressure within a system. It works by transmitting pressure readings from one part of the system to a sensor or gauge, allowing for precise control and adjustment of pressure levels. This is vital for ensuring that systems operate within safe and efficient parameters, preventing damage and enhancing performance 1.

Purpose of the Cummins 3938926 Pressure Sensing Tube

The Cummins 3938926 Pressure Sensing Tube plays a role in the truck’s system by facilitating accurate pressure monitoring. It is integral to the engine or other systems where pressure regulation is necessary. By providing consistent and reliable pressure readings, it helps in maintaining optimal system performance and efficiency.

Key Features

The Cummins 3938926 Pressure Sensing Tube is characterized by several key features that enhance its performance. These include its material composition, which is designed to withstand the pressures and temperatures encountered in commercial truck applications. Its design elements are tailored to ensure accurate pressure transmission and durability over time.

Benefits

Using the Cummins 3938926 Pressure Sensing Tube offers several benefits. It contributes to improved system efficiency by ensuring that pressure levels are accurately monitored and maintained. Its durable construction leads to enhanced longevity, reducing the need for frequent replacements. Additionally, by promoting efficient system operation, it can lead to potential cost savings for fleet operators through reduced maintenance and operational costs.

Installation and Integration

Proper installation and integration of the Cummins 3938926 Pressure Sensing Tube are crucial for its effective operation. Guidelines for installation include ensuring that the tube is correctly positioned within the system to allow for accurate pressure readings. It is also important to follow any manufacturer-specified procedures to avoid damaging the component or affecting system performance.

Troubleshooting and Maintenance

Common issues with the Cummins 3938926 Pressure Sensing Tube may include inaccurate pressure readings or physical damage to the tube. Troubleshooting these issues involves checking the tube for any signs of wear or damage and ensuring that it is correctly installed. Regular maintenance, such as inspecting the tube for leaks or blockages, can help ensure optimal performance and longevity.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck components industry. With a history of innovation and a commitment to quality, Cummins has built a reputation for producing reliable and high-performance parts. Their focus on advancing technology and meeting the needs of their customers underscores their position as a leader in the industry 2.

Role of Part 3938926 Pressure Sensing Tube in Engine Systems

The Cummins 3938926 Pressure Sensing Tube is integral to the efficient operation of engine systems, particularly in ensuring accurate pressure readings and maintaining system integrity.

Integration with Plumbing Systems

In engine systems, the Pressure Sensing Tube is often connected to the plumbing network. This connection allows the tube to channel pressure readings from various points within the system to the sensors. The tube’s precise fit and secure connection to the plumbing ensure that pressure readings are transmitted without loss or distortion, contributing to the overall reliability of the engine’s performance monitoring.

Interaction with Sensors

The Pressure Sensing Tube plays a significant role in the accurate functioning of sensors within the engine system. By providing a direct pathway for pressure data, the tube ensures that sensors receive real-time, uncontaminated pressure information. This direct data feed is essential for sensors to make precise calculations and adjustments, which are vital for the engine’s optimal operation. The tube’s design facilitates a consistent and stable connection to the sensors, enhancing the accuracy and responsiveness of the engine’s pressure monitoring capabilities.

Conclusion

The Cummins 3938926 Pressure Sensing Tube is a critical component in the maintenance and optimization of commercial truck performance. Its role in accurate pressure monitoring and system efficiency makes it an essential part of the truck’s system. Proper installation, regular maintenance, and understanding its integration with other system components are key to leveraging its benefits fully.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.