This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

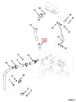

The Cummins 3958154 Crankshaft Pulley is a component designed for use in commercial truck engines. Its purpose is to facilitate the operation of various engine accessories by transferring rotational force from the crankshaft. This pulley is significant in ensuring the efficient and reliable performance of truck engines, contributing to the overall functionality and durability of the vehicle.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is a toothed wheel attached to the front of an engine’s crankshaft. Its primary function is to drive engine accessories such as the alternator, power steering pump, and air conditioning compressor via a belt or chain. The pulley ensures these components receive the necessary rotational force to operate correctly. It also helps in reducing vibrations produced by the engine, contributing to smoother operation 1.

Purpose of the 3958154 Crankshaft Pulley

The 3958154 Crankshaft Pulley plays a role in the operation of a truck engine by driving various engine accessories. It is responsible for transferring the rotational energy from the crankshaft to these accessories, ensuring they function as intended. This pulley is integral to maintaining the balance and efficiency of the engine, as it helps manage the distribution of power and reduces mechanical stress on the crankshaft 2.

Key Features

The Cummins 3958154 Crankshaft Pulley is constructed with high-quality materials to ensure durability and performance. It features a robust design that includes a dampening element to absorb vibrations, which helps in maintaining engine smoothness. The pulley is engineered to withstand the high stresses and temperatures encountered in commercial truck engines, ensuring long-lasting operation 3.

Benefits

The 3958154 Crankshaft Pulley offers several advantages. It contributes to improved engine performance by ensuring efficient power transfer to engine accessories. Its durable construction and high-quality materials enhance the longevity of the component. Additionally, the pulley’s design helps in reducing engine vibrations, leading to a more stable and efficient engine operation 4.

Installation Process

Installing the 3958154 Crankshaft Pulley requires careful attention to detail. The process involves aligning the pulley with the crankshaft and securing it with the appropriate fasteners. It is important to use the correct tools and follow the manufacturer’s guidelines to ensure proper installation. This may include using a pulley puller to remove the old pulley and a torque wrench to tighten the new one to the specified torque settings 5.

Common Issues and Troubleshooting

Typical problems associated with crankshaft pulleys include wear and tear, misalignment, and damage to the dampening element. Diagnosing issues may involve inspecting the pulley for signs of wear, checking the alignment with the crankshaft, and ensuring the belt or chain is properly tensioned. Recommended solutions include replacing worn components, realigning the pulley, and ensuring all fasteners are secure 6.

Maintenance Tips

To ensure the longevity and optimal performance of the 3958154 Crankshaft Pulley, routine maintenance practices should be followed. This includes regular inspection for signs of wear or damage, ensuring proper alignment, and maintaining the correct tension on the belt or chain. Additionally, keeping the pulley clean and free from debris will help prevent premature wear and ensure efficient operation 7.

Compatibility and Applications

The Cummins 3958154 Crankshaft Pulley is designed for specific engines and truck models. It is important to verify compatibility with the engine make and model to ensure proper fit and function. This pulley is commonly used in various commercial truck applications, providing reliable performance in demanding environments 8.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable, and efficient engine components. The company’s extensive product range includes a variety of engine parts and accessories designed to meet the needs of commercial vehicle operators worldwide.

Cummins Crankshaft Pulley Part 3958154 Compatibility

The Cummins crankshaft pulley part number 3958154 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is integral to the engine’s operation, as it connects the crankshaft to the engine’s accessory belt, facilitating the transfer of power to essential components such as the alternator, water pump, and air conditioning compressor.

ISB CM850 Engines

The ISB CM850 engine series, known for its robust performance and efficiency, is one of the primary beneficiaries of the 3958154 crankshaft pulley. This engine is widely used in various applications, including heavy-duty trucks, construction equipment, and industrial machinery. The compatibility of the 3958154 pulley with the ISB CM850 ensures that the engine maintains its high standards of performance and durability.

Grouping of Compatible Engines

While the ISB CM850 is a notable example, the 3958154 crankshaft pulley is also compatible with other Cummins engine models within the same family. These engines share similar design characteristics and operational requirements, making the 3958154 pulley a versatile and reliable choice for multiple applications. The compatibility extends to engines that require a robust and efficient crankshaft pulley to support their demanding operational needs.

Role of Part 3958154 Crankshaft Pulley in Engine Systems

The 3958154 Crankshaft Pulley is an integral component in the efficient operation of engine systems, particularly in its interaction with the breather and crankcase components.

Interaction with the Breather System

The breather system is designed to manage the pressure within the crankcase by allowing air and gases to escape. The 3958154 Crankshaft Pulley, through its rotational motion, helps in maintaining the balance of the engine’s internal pressures. As the pulley rotates, it ensures that the crankshaft’s movement is smooth and consistent, which in turn supports the breather system’s function of expelling excess gases and maintaining optimal pressure levels within the crankcase 9.

Contribution to Crankcase Efficiency

The crankcase serves as the lower part of the engine block, housing the crankshaft and connecting rods. The 3958154 Crankshaft Pulley plays a significant role in the crankcase by driving various engine accessories through a series of belts or chains. This includes components like the alternator, water pump, and air conditioning compressor. The pulley’s efficient operation ensures that these accessories receive the necessary power to function correctly, which is essential for the overall performance and longevity of the engine 10.

Conclusion

In summary, the 3958154 Crankshaft Pulley is a key component that facilitates the smooth operation of the breather system and enhances the efficiency of the crankcase, thereby contributing to the engine’s reliable performance. Its robust design, compatibility with various Cummins engines, and role in maintaining engine balance and efficiency make it a critical part of commercial truck engine systems.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

Mobile Equipment Hydraulics A Systems and Troubleshooting Approach, Ben Watson, Cengage Learning, 2011

↩ -

Automobile Wheel Alignment and Wheel Balancing, R Mananathan, SAE International, 2022

↩ -

Engine L8.9G CMOH2.0 L125B, Bulletin Number 5504209, Operation and Maintenance Manual

↩ -

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

Mobile Equipment Hydraulics A Systems and Troubleshooting Approach, Ben Watson, Cengage Learning, 2011

↩ -

Automobile Wheel Alignment and Wheel Balancing, R Mananathan, SAE International, 2022

↩ -

Engine L8.9G CMOH2.0 L125B, Bulletin Number 5504209, Operation and Maintenance Manual

↩ -

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

Mobile Equipment Hydraulics A Systems and Troubleshooting Approach, Ben Watson, Cengage Learning, 2011

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.