This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

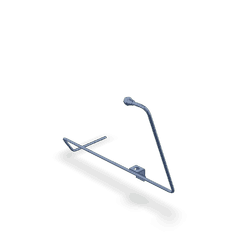

The Cummins 3976601 Pressure Sensing Tube is a component designed for use in heavy-duty trucks. It serves a specific function within the truck’s systems, contributing to the overall performance and safety of the vehicle. Understanding its purpose and significance can provide valuable insights into the complexities of heavy-duty truck operations.

Basic Concepts of Pressure Sensing Tubes

Pressure sensing tubes are components used to monitor and regulate pressure within various systems. They work by transmitting pressure readings from one part of the system to another, allowing for precise control and adjustment. These tubes play a role in ensuring that systems operate within safe and efficient pressure ranges, which is vital for the performance and longevity of the equipment 1.

Purpose of the 3976601 Pressure Sensing Tube

The Cummins 3976601 Pressure Sensing Tube is designed to play a specific role in the operation of a truck. It is integrated within the truck’s systems to monitor and transmit pressure readings, which are then used to make adjustments and ensure optimal performance. This component is part of a larger system that relies on accurate pressure readings to function correctly.

Key Features

The 3976601 Pressure Sensing Tube is characterized by several key features that enhance its performance. These include its material composition, which is designed to withstand the pressures and temperatures encountered in heavy-duty truck applications. The design elements of the tube also contribute to its effectiveness, ensuring that it can accurately transmit pressure readings under various conditions.

Benefits

The advantages provided by the 3976601 Pressure Sensing Tube include improved system efficiency and enhanced safety. By accurately monitoring and regulating pressure, this component helps to ensure that the truck’s systems operate within safe parameters. This can lead to increased reliability and performance, as well as reduced risk of system failures or malfunctions.

Installation and Integration

Proper installation and integration of the 3976601 Pressure Sensing Tube within a truck’s system are important for ensuring optimal performance. Guidelines for installation should be followed carefully, including any necessary precautions or considerations. This may involve ensuring that the tube is properly connected to other components and that it is secured in place to prevent damage or disconnection.

Troubleshooting and Maintenance

Common issues related to the 3976601 Pressure Sensing Tube may include inaccurate pressure readings or system malfunctions. Troubleshooting these issues may involve checking the connections and ensuring that the tube is properly installed. Regular maintenance practices, such as inspecting the tube for signs of wear or damage, can help to ensure optimal performance and longevity.

Cummins Overview

Cummins is a company with a long history of manufacturing automotive components. It is known for its commitment to quality and innovation, and its products are widely used in the industry. The company’s reputation for producing reliable and high-performing components makes it a trusted choice for many heavy-duty truck applications.

Pressure Sensing Tube (Part 3976601) Compatibility with Cummins Engines

The Pressure Sensing Tube, identified by part number 3976601, is a critical component in Cummins engines, ensuring accurate pressure readings for optimal engine performance. This part is designed to fit seamlessly within specific Cummins engine models, enhancing the engine’s operational efficiency and reliability.

B5.9 GAS PLUS CM556

The B5.9 GAS PLUS CM556 engine is one of the models that benefit from the Pressure Sensing Tube. This engine is known for its robust design and efficient performance, particularly in applications requiring high power output. The Pressure Sensing Tube in this engine model ensures precise pressure monitoring, which is essential for maintaining the engine’s performance and longevity.

Integration and Functionality

The Pressure Sensing Tube is engineered to integrate smoothly with the engine’s pressure systems. It is typically positioned in a way that allows it to accurately measure the pressure within the engine’s system. This placement is crucial for the engine control unit (ECU) to make real-time adjustments, ensuring the engine operates within optimal parameters.

Importance of the Pressure Sensing Tube

The Pressure Sensing Tube plays a vital role in the engine’s overall health and performance. By providing accurate pressure data, it helps prevent potential issues such as over-pressurization, which can lead to engine damage. Additionally, it aids in maintaining fuel efficiency and reducing emissions, making it an indispensable part of modern engine systems.

Compatibility Considerations

When replacing or installing the Pressure Sensing Tube in Cummins engines, it is essential to ensure that the part number matches the specific engine model. This compatibility is crucial for maintaining the engine’s performance and ensuring that the Pressure Sensing Tube functions correctly within the engine’s system.

Role of Part 3976601 Pressure Sensing Tube in Engine Systems

The part 3976601 Pressure Sensing Tube is an integral component in the orchestration of various engine systems, ensuring optimal performance and efficiency. Its primary function is to facilitate the accurate measurement and regulation of pressure within the engine’s operational environment.

Integration with Plumbing Systems

In the context of engine plumbing, the Pressure Sensing Tube is meticulously positioned to interface with the fluid dynamics of the system. It is connected to key points within the plumbing network, allowing for the precise monitoring of pressure variations. This data is essential for maintaining the integrity of the plumbing system, preventing leaks, and ensuring that fluid flow is consistent and within specified parameters.

Interaction with Sensors

The Pressure Sensing Tube works in tandem with pressure sensors to provide real-time data on the engine’s internal pressure conditions. This tube acts as a conduit, transferring pressure readings from various points within the engine to the sensors. The sensors, in turn, convert these physical pressure signals into electrical signals that can be interpreted by the engine’s control unit. This continuous feedback loop is vital for the dynamic adjustment of engine parameters, such as fuel injection timing and valve operation, to adapt to changing conditions.

Contribution to Pressure Sensing Systems

Within the broader pressure sensing system of an engine, the Pressure Sensing Tube is a pivotal element. It is designed to withstand the harsh conditions of the engine environment, including high temperatures and corrosive substances, ensuring reliable pressure readings over time. The tube’s placement is strategic, often near critical components like the turbocharger, intercooler, or fuel system, where pressure fluctuations can significantly impact performance and efficiency.

Conclusion

In summary, the part 3976601 Pressure Sensing Tube is a fundamental component that enhances the functionality of engine systems by providing accurate and consistent pressure data. Its integration with plumbing, sensors, and the overall pressure sensing system underscores its importance in maintaining engine health and performance.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.