This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

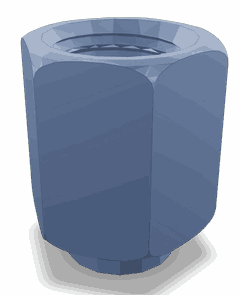

The Tube End Cap 4000616, manufactured by Cummins, is a component designed for use in commercial truck systems. Its purpose is to provide a secure closure for tubes within the truck’s fluid systems, ensuring the integrity and efficiency of these systems. Cummins, a well-regarded manufacturer in the automotive industry, produces this part with a focus on quality and reliability 1.

Basic Concepts of Tube End Caps

Tube end caps are components used to seal the ends of tubes in fluid systems. They prevent fluid leakage and protect the internal components of the tube from external contaminants. These caps operate by fitting snugly over the tube’s end, creating a barrier that maintains system pressure and fluid containment. Materials commonly used in the construction of tube end caps include metals like steel and aluminum, chosen for their durability and resistance to corrosion 2.

Purpose of the 4000616 Tube End Cap in Truck Operations

The 4000616 Tube End Cap plays a specific role in the operation of commercial trucks by sealing the ends of tubes in various fluid systems. This sealing function contributes to the efficiency and reliability of the truck’s systems by maintaining fluid pressure, preventing leaks, and protecting the system from contaminants. Its role is vital in ensuring that the truck’s fluid systems operate smoothly and efficiently 3.

Key Features of the 4000616 Tube End Cap

The 4000616 Tube End Cap is characterized by several key features that enhance its performance and durability. Its design ensures a tight fit over the tube ends, providing a secure seal. The material used in its construction is selected for its strength and resistance to the corrosive effects of fluids, ensuring longevity. Additionally, any unique attributes, such as a specific coating or threading, further contribute to its effectiveness in sealing and protecting the tube ends 4.

Benefits of Using the 4000616 Tube End Cap

Incorporating the 4000616 Tube End Cap into truck systems offers several advantages. It improves system integrity by providing a reliable seal that prevents fluid leakage. Enhanced performance is achieved through the maintenance of system pressure and the protection of internal components from contaminants. Furthermore, the durability of the 4000616 Tube End Cap contributes to the longevity of the truck’s fluid systems, reducing the need for frequent replacements and repairs 5.

Installation and Compatibility

Proper installation of the 4000616 Tube End Cap is crucial for its effectiveness. It should be fitted securely over the tube ends, ensuring a tight seal. Compatibility with various truck models and systems is an important consideration, as the 4000616 Tube End Cap is designed to meet the specific requirements of commercial truck fluid systems. Ensuring compatibility helps maintain the efficiency and reliability of these systems 6.

Troubleshooting and Maintenance

Common issues associated with tube end caps include leaks and corrosion. Troubleshooting these issues involves inspecting the cap for signs of damage or wear and ensuring it is properly fitted. Maintenance tips for the 4000616 Tube End Cap include regular inspection for signs of corrosion or damage, cleaning to remove any contaminants, and replacing the cap if it shows signs of wear or if a leak is detected. These practices help ensure the longevity and optimal performance of the tube end cap 7.

Cummins: Manufacturer Overview

Cummins is a manufacturer with a strong reputation in the automotive industry, known for its commitment to quality and innovation in automotive components. With a history of producing reliable and high-performance parts, Cummins has established itself as a trusted name in the industry. Their focus on quality and innovation is evident in the design and construction of the 4000616 Tube End Cap, reflecting their dedication to providing components that meet the demanding requirements of commercial truck systems 8.

Compatibility of Cummins Tube End Cap 4000616

The Tube End Cap, part number 4000616, manufactured by Cummins, is designed to fit seamlessly within the engine systems, ensuring optimal performance and reliability. Here is a detailed look at its compatibility across various Cummins engines:

QSK50 and CM2150 Engines

The Tube End Cap part 4000616 is specifically engineered to integrate with the QSK50 and CM2150 engines. These engines are known for their robust design and high performance, often used in heavy-duty applications such as marine and industrial sectors. The cap’s precision fit ensures that it effectively seals the tube, preventing any leaks and maintaining the integrity of the engine’s cooling system 9.

MCRS and V903 Engines

Similarly, the Tube End Cap part 4000616 is also compatible with the MCRS and V903 engines. These engines are designed for versatility and efficiency, often used in a variety of applications, including construction and agricultural machinery. The cap’s design ensures that it fits snugly within the engine’s architecture, providing a reliable seal that is crucial for the engine’s operation 10.

Role of Part 4000616 Tube End Cap in Engine Systems

The Tube End Cap, identified by part number 4000616, is a component in various engine systems, ensuring the integrity and efficiency of fuel delivery and regulation.

In the arrangement of engine components, the Tube End Cap is strategically positioned to seal the ends of fuel supply tubing. This prevents any leakage or contamination, maintaining the purity and pressure of the fuel as it travels through the system.

When integrated with the pressure regulator valve, the Tube End Cap helps maintain consistent fuel pressure. By sealing the tubing, it ensures that the pressure regulator can accurately control the fuel pressure, which is vital for the engine’s performance and efficiency.

In conjunction with the fuel supply tubing, the Tube End Cap plays a role in securing the tubing ends, preventing any fuel loss or air intake that could disrupt the fuel flow. This ensures a steady and reliable supply of fuel to the engine.

The fuel transfer kit often includes various tubing components that require sealing. The Tube End Cap is used to cap off the ends of these tubes, ensuring that the transfer process is smooth and free from leaks, which could otherwise lead to inefficiencies or safety hazards.

Lastly, in the context of fuel tubing, the Tube End Cap is employed to seal any open ends, protecting the fuel line from external contaminants and ensuring that the fuel remains clean and pressurized as it moves through the system. This is particularly important in high-performance engines where fuel purity and pressure are paramount.

Overall, the Tube End Cap (part 4000616) is a small yet significant component that contributes to the overall reliability and efficiency of engine systems by ensuring secure and leak-free connections in fuel delivery pathways 11.

Conclusion

The 4000616 Tube End Cap by Cummins is a critical component in maintaining the integrity and efficiency of commercial truck and engine systems. Its design and material selection ensure durability and resistance to corrosion, contributing to the longevity of the systems it serves. Proper installation, regular maintenance, and understanding its compatibility with various engine models are essential for maximizing its benefits. Cummins’ reputation for quality and innovation is reflected in the performance and reliability of this part, making it a valuable asset in the operation and maintenance of commercial vehicles.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Cummins. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579971.

↩ -

Cummins. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579971.

↩ -

Cummins. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579971.

↩ -

Cummins. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579971.

↩ -

Cummins. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579971.

↩ -

Cummins. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579971.

↩ -

Cummins. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579971.

↩ -

Cummins. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579971.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.