This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

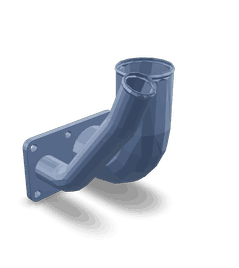

The Cummins 4006887 Breather Tube is a component designed for use in commercial trucks equipped with Cummins engines. Its purpose is to facilitate the release of pressure and contaminants from the engine’s crankcase, ensuring optimal engine performance and longevity. This part is integral to the engine’s ventilation system, contributing to the overall efficiency and reliability of the vehicle 1.

Function and Operation

The Breather Tube operates by allowing air and gases to escape from the engine’s crankcase. This process helps maintain pressure equilibrium within the crankcase, preventing the buildup of harmful contaminants such as moisture and sludge. By venting these substances, the breather tube ensures that the engine oil remains clean and effective, thereby supporting the engine’s lubrication system and overall performance 2.

Key Features

This Cummins part is characterized by its durable construction and precise engineering. It is designed to withstand the demanding conditions of commercial truck operations, ensuring long-lasting performance. The tube is specifically engineered to be compatible with Cummins engines, guaranteeing a seamless fit and function within the engine’s ventilation system 3.

Benefits

The use of the 4006887 offers several benefits. It contributes to improved engine performance by ensuring that the crankcase remains free of contaminants. This results in enhanced engine durability, as clean oil is better able to lubricate moving parts and prevent wear. Additionally, the breather tube reduces maintenance requirements by minimizing the need for frequent oil changes and system cleanouts 4.

Installation and Maintenance

Proper installation of the 4006887 involves ensuring a secure fit within the engine’s ventilation system, following manufacturer guidelines. Regular maintenance includes periodic inspections to check for blockages or damage. It is recommended to inspect the breather tube during routine engine maintenance checks, ensuring it remains in optimal condition 5.

Common Issues and Troubleshooting

Common issues associated with breather tubes include blockages or leaks. Blockages can occur due to the accumulation of contaminants, while leaks may result from wear or improper installation. Troubleshooting steps include visual inspection for signs of damage or obstruction, and testing the system for proper ventilation. Addressing these issues promptly can prevent more significant engine problems 6.

Importance in Engine Health

The 4006887 plays a role in maintaining engine health by ensuring proper lubrication, preventing contamination, and contributing to overall engine efficiency. By facilitating the release of pressure and contaminants from the crankcase, the breather tube helps maintain clean oil, which is vital for the engine’s moving parts. This contributes to the engine’s longevity and performance 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company offers a wide range of products designed to meet the diverse needs of its customers, ensuring optimal performance and efficiency in various applications.

Cummins Breather Tube 4006887 Compatibility

The Cummins Breather Tube part number 4006887 is designed to fit seamlessly within various Cummins engine models. This component is engineered to maintain optimal air pressure within the engine’s crankcase, ensuring efficient engine operation and longevity.

QSK78 Series

The QSK78 series engines, known for their robust performance and reliability, are compatible with the Breather Tube 4006887. This part is crucial in managing the air pressure within the crankcase, preventing contaminants from entering and ensuring the engine runs smoothly.

CM500 Series

Similarly, the CM500 series engines benefit from the integration of the Breather Tube 4006887. This part is engineered to fit precisely within the engine’s design, providing a reliable method for air pressure management. The CM500 series is renowned for its efficiency and durability, and the Breather Tube plays a key role in maintaining these qualities.

Group Compatibility

The Breather Tube 4006887 is not limited to individual engine models but is also compatible with various engine groups within the Cummins lineup. This versatility ensures that the part can be used across different applications, providing a consistent and reliable solution for air pressure management in Cummins engines.

Role of Part 4006887 Breather Tube in Engine Systems

The part 4006887 Breather Tube is an essential component in maintaining the health and efficiency of engine systems by facilitating the proper ventilation of the crankcase. This breather tube allows for the release of pressure and the expulsion of contaminants that accumulate within the crankcase during engine operation.

Integration with the Crankcase

The breather tube is directly connected to the crankcase, which houses the crankshaft and connecting rods. As the engine runs, it generates heat and pressure within the crankcase. The breather tube provides a pathway for these byproducts to escape, preventing a buildup that could lead to increased wear on engine components and reduced performance.

Function in the Ventilation System

In conjunction with the Positive Crankcase Ventilation (PCV) system, the breather tube plays a significant role in circulating air through the crankcase. It helps in drawing in fresh air while allowing the escape of gases that contain moisture, unburnt fuel, and other debris. This continuous airflow helps in keeping the crankcase clean and dry, which is vital for the longevity of the engine.

Contribution to Engine Health

By ensuring that the crankcase remains at an optimal pressure and free from contaminants, the breather tube contributes to the overall health of the engine. It aids in reducing the formation of sludge and varnish, which can otherwise lead to engine seizing or other severe mechanical issues. Additionally, it helps in maintaining the integrity of the engine oil by preventing the dilution of oil with contaminants, thus ensuring that the oil performs its lubricating function effectively.

Interaction with Other Components

The breather tube also interacts with other engine components such as the air intake system. In some designs, the breather tube is connected to the intake manifold, allowing the expelled gases to be reintroduced into the combustion process. This not only helps in reducing emissions but also ensures that any unburnt fuel is utilized, contributing to better fuel efficiency.

Conclusion

In summary, the part 4006887 Breather Tube is a key player in the ventilation and maintenance of the crankcase, interacting with various engine components to ensure optimal engine performance and longevity. Its role in maintaining clean oil, preventing contamination, and ensuring proper ventilation is crucial for the overall health and efficiency of Cummins engines.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Hilgers, M. (2022). The Drivers Cab. Springer Vieweg.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Hilgers, M. (2022). The Drivers Cab. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.