This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

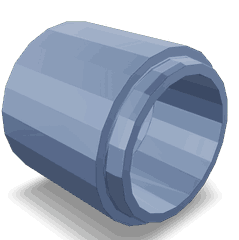

The Cummins 4012829 Coupling Tube is a component designed for use in commercial trucks, facilitating connections within the vehicle’s systems. Manufactured by Cummins, a reputable name in the automotive industry, this part is integral to the efficient operation of trucks. Cummins’ reputation for quality and innovation makes its components trusted choices for fleet operators and maintenance professionals.

Purpose and Function

The Cummins 4012829 Coupling Tube serves to connect different components within a truck’s system, allowing for the efficient transfer of fluids or gases. Its design ensures systems operate smoothly and effectively by providing a secure and reliable connection point. This contributes to the overall functionality and performance of the truck 1.

Key Features

Constructed from high-quality materials, the Cummins 4012829 Coupling Tube ensures durability and resistance to wear and corrosion. Its design includes precision-machined connections for a tight seal and robust construction to withstand high pressure and temperature variations. These features enhance the coupling tube’s reliability and longevity in demanding commercial truck applications 2.

Benefits

Utilizing the Cummins 4012829 Coupling Tube offers several advantages. It contributes to improved system efficiency by ensuring secure and leak-free connections. The design reduces the likelihood of maintenance issues, leading to lower overall maintenance requirements. Additionally, its reliable performance enhances the dependability of the truck’s systems, providing peace of mind to operators and fleet managers 3.

Installation Process

Installing the Cummins 4012829 Coupling Tube requires careful attention to detail to ensure a secure and effective fit. Preparatory steps include cleaning the connection points and inspecting the tube for any damage. The installation process involves aligning the coupling tube with the connection points and securing it in place using the appropriate tools. Following best practices during installation helps to prevent leaks and ensures the coupling tube functions as intended 4.

Common Issues and Troubleshooting

Despite its robust design, the Cummins 4012829 Coupling Tube may encounter issues such as leaks or connection failures over time. Common causes include wear and tear, improper installation, or exposure to extreme conditions. Troubleshooting these issues involves inspecting the coupling tube and connection points for signs of damage or misalignment. Solutions may include tightening connections, replacing worn components, or addressing external factors that contribute to the problem.

Maintenance Tips

Regular maintenance is key to prolonging the lifespan of the Cummins 4012829 Coupling Tube. Inspection routines should be conducted to check for signs of wear, corrosion, or leaks. Cleaning the coupling tube and its connections can help prevent buildup that may affect performance. Knowing when to consider replacement is also important; if the coupling tube shows significant wear or fails to maintain a secure connection, it may be time for a replacement to ensure the continued efficiency and reliability of the truck’s systems.

Compatibility and Applications

The Cummins 4012829 Coupling Tube is designed for use in specific types of trucks and systems, catering to the needs of commercial fleet operators. It is commonly applied in models where reliable fluid or gas transfer is critical to operation. Understanding the compatibility of this coupling tube with your truck’s system ensures optimal performance and integration.

Manufacturer Overview - Cummins

Cummins is a leader in the automotive industry, with a history of innovation and commitment to quality. The company offers a wide range of products designed for various applications, from commercial trucks to industrial engines. Cummins’ dedication to excellence is evident in its product development processes, which prioritize durability, efficiency, and reliability. This commitment has earned Cummins a respected position in the industry, making its components, including the 4012829 Coupling Tube, preferred choices for professionals seeking dependable solutions for their vehicles.

Role of Part 4012829 Coupling Tube in Engine Systems

The 4012829 Coupling Tube is an essential component in the efficient operation of various engine systems. It facilitates the connection between the camshaft and the connecting rod and piston assembly, ensuring smooth transmission of motion and power.

In the context of the cylinder (pressure test) head and the cylinder assembly head, the Coupling Tube plays a significant role in maintaining the integrity of the pressure systems. It ensures that the pressure within the cylinder head is evenly distributed, which is vital for optimal engine performance.

Furthermore, the Coupling Tube is integral to the overall cylinder head and head cylinder interaction. It helps in synchronizing the movement between these components, which is necessary for the precise timing required in engine operation.

In summary, the 4012829 Coupling Tube is a key element in the coordination and efficiency of engine parts, directly influencing the performance and reliability of the engine system.

Conclusion

The Cummins 4012829 Coupling Tube is a vital component in the operation of commercial trucks, offering durability, efficiency, and reliability. Its role in connecting various systems within the vehicle ensures smooth and effective operation. Regular maintenance and proper installation are crucial to maximizing its benefits and longevity.

-

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing, 2011.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Fischer, Robert, et al. The Automotive Transmission Book Powertrain. Springer, 2015.

↩ -

Aird, Forbes. Bosch Fuel Injection Systems. HP Books, 2001.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.