This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

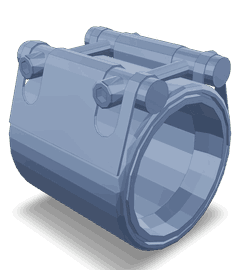

The Cummins 4013810 Tube Connector is a component designed for use in commercial trucks. It serves a specific function within the truck’s fluid systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance can help in maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Tube Connectors

Tube connectors are components used in fluid systems to join different sections of tubing or piping. They facilitate the transfer of fluids such as fuel, coolant, or hydraulic fluid throughout the vehicle. In a truck’s infrastructure, these connectors ensure that fluid lines are securely joined, allowing for uninterrupted flow and reducing the risk of leaks. They are integral to maintaining the integrity and functionality of the fluid systems 1.

Purpose of the 4013810 Tube Connector

The Cummins 4013810 Tube Connector is designed to connect various fluid lines within a truck. Its role is to ensure that the connection between these lines is secure and that fluid can flow smoothly from one part of the system to another. This connector is particularly important in systems where precise fluid management is required, such as in the engine cooling or hydraulic systems.

Key Features

The Cummins 4013810 Tube Connector is constructed with materials that are resistant to corrosion and high temperatures, ensuring durability in harsh operating conditions. It features a design that allows for easy connection and disconnection, which simplifies maintenance and repair processes. The connector may include specific fittings or seals that enhance its performance and reliability.

Benefits

Using the Cummins 4013810 Tube Connector offers several advantages. Its robust construction contributes to improved reliability, reducing the likelihood of failures in the fluid system. The design of the connector also facilitates ease of installation, which can save time during maintenance procedures. Additionally, its durability ensures that it can withstand the demanding conditions typical of commercial truck operations.

Installation Process

Installing the Cummins 4013810 Tube Connector involves several steps to ensure a secure and proper connection. First, the appropriate tools should be gathered, which may include wrenches and sealants. The connector should be aligned with the fluid lines and then tightened to the manufacturer’s specified torque. It is important to follow the installation instructions carefully to avoid damage to the connector or the fluid lines.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4013810 Tube Connector, regular maintenance is recommended. This includes inspecting the connector for signs of wear or damage, such as cracks or leaks, at regular intervals. Cleaning the connector and its surrounding areas can also help prevent buildup that might affect its function. Following these maintenance practices can help in identifying potential issues before they become serious problems.

Troubleshooting Common Issues

Common issues with the Cummins 4013810 Tube Connector may include leaks or corrosion. If a leak is detected, it is important to identify the source and make the necessary repairs or replacements. Corrosion can be addressed by cleaning the affected areas and applying a protective coating. Regular inspections can help in early detection of these issues, allowing for timely intervention.

Compatibility and Usage

The Cummins 4013810 Tube Connector is designed for use in various truck models and systems, demonstrating its versatility. It is commonly used in applications where reliable fluid connections are crucial, such as in engine cooling or hydraulic systems. Understanding its typical applications can help in selecting the appropriate connector for specific needs.

Safety Considerations

When working with the Cummins 4013810 Tube Connector, it is important to follow safety guidelines. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Additionally, ensuring that the truck’s engine is off and the fluid systems are depressurized before beginning any work can help prevent accidents.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies. With a history of innovation and quality, Cummins has established itself as a trusted name in the industry. The company’s commitment to excellence is reflected in its products, including the Cummins 4013810 Tube Connector, which is designed to meet the high standards required for commercial truck applications.

Role of Part 4013810 Tube Connector in Engine Systems

The part 4013810 Tube Connector is an essential component in the arrangement of various engine systems, facilitating efficient and secure connections between different parts.

In the context of a turbocharger, the Tube Connector ensures a reliable connection between the turbocharger and the engine’s plumbing system. This connection is vital for the proper flow of exhaust gases, which drive the turbocharger and enhance engine performance.

For the water inlet system, the Tube Connector plays a significant role in connecting the water inlet to the engine coolant passages. This ensures that coolant is efficiently circulated through the engine, maintaining optimal operating temperatures and preventing overheating.

When integrated with the drive and accessory systems, the Tube Connector provides a stable and leak-free connection for various fluid lines. This is particularly important for systems that require consistent fluid pressure and flow, such as hydraulic or pneumatic drives.

In the plumbing of the engine coolant system, the Tube Connector ensures that all components, including the pump and radiator, are securely linked. This promotes efficient coolant circulation, which is essential for dissipating heat generated by the engine.

Overall, the Tube Connector is a fundamental component in maintaining the integrity and efficiency of various engine systems by providing secure and reliable connections.

Conclusion

The Cummins 4013810 Tube Connector is a vital component in the fluid systems of commercial trucks, ensuring secure and efficient connections between various fluid lines. Its robust construction, ease of installation, and durability make it a reliable choice for maintaining the performance and reliability of commercial vehicles. Regular maintenance and adherence to safety guidelines are essential for maximizing the lifespan and effectiveness of this Cummins part.

-

Rudolf Limpert, Brake Design and Safety, Third Edition, SAE International, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.