This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

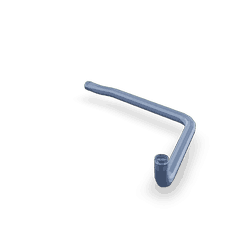

The Cummins 4019922 Breather Tube is a component designed for use in heavy-duty truck engines. Its purpose is to facilitate the release of pressure and the exchange of air within the engine system, contributing to the overall efficiency and reliability of the engine. This breather tube is integral to maintaining optimal engine performance by ensuring that pressure levels are regulated and that contaminants are minimized within the engine’s crankcase 1.

Basic Concepts of Breather Tubes

A breather tube is a component found in engine systems that allows for the release of pressure and the exchange of air. It operates on the principle that as an engine runs, it produces gases and pressure within the crankcase. The breather tube provides a pathway for these gases to escape, preventing a buildup of pressure that could lead to leaks or damage. Additionally, it allows fresh air to enter the crankcase, which helps to carry away moisture and contaminants, maintaining a clean environment for the engine’s moving parts 2.

Purpose of the Cummins 4019922 Breather Tube

The Cummins 4019922 Breather Tube plays a specific role in the engine system by regulating pressure and facilitating ventilation. It ensures that the crankcase maintains a balanced pressure, which is vital for the proper operation of the engine. By allowing gases to escape and fresh air to enter, it helps in reducing the accumulation of moisture and contaminants, which can otherwise lead to sludge formation and increased wear on engine components 3.

Key Features

The Cummins 4019922 Breather Tube is constructed from durable materials that are resistant to the high temperatures and pressures found within an engine environment. Its design includes features such as a filtration system to trap particles and prevent them from entering the engine, and a venting mechanism that allows for the efficient release of gases. These characteristics contribute to the breather tube’s performance and longevity.

Benefits of Using the Cummins 4019922 Breather Tube

Installing the Cummins 4019922 Breather Tube offers several advantages. It contributes to improved engine performance by ensuring that the crankcase operates under optimal pressure conditions. The breather tube also enhances engine longevity by reducing the risk of contamination and wear on internal components. Furthermore, its reliable design supports the overall reliability of the engine system, providing peace of mind to operators and maintenance personnel.

Installation Process

To install the Cummins 4019922 Breather Tube, begin by ensuring the engine is cool and the vehicle is parked on a level surface. Gather the necessary tools, which may include wrenches and a socket set. Locate the existing breather tube and disconnect it from the crankcase. Carefully remove the old tube, taking note of its orientation and connections. Install the Cummins 4019922 Breather Tube in the reverse order of removal, ensuring all connections are secure. Finally, start the engine and check for any leaks or unusual noises, making adjustments as necessary.

Maintenance Tips

Regular maintenance of the Cummins 4019922 Breather Tube is important for ensuring its efficient operation. Inspect the tube periodically for signs of wear or damage, and clean the filtration system as recommended by the manufacturer. Check the connections to ensure they remain secure and free from leaks. Following these maintenance practices will help in prolonging the life of the breather tube and maintaining engine performance.

Troubleshooting Common Issues

Common issues with breather tubes may include leaks, blockages, or contamination. If a leak is detected, inspect the connections and seals for damage or wear. Blockages can often be resolved by cleaning the filtration system or replacing the breather tube if necessary. Contamination within the crankcase may indicate a failure in the breather tube’s filtration system, requiring inspection and potential replacement.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company is committed to providing reliable and efficient components that meet the demanding requirements of heavy-duty applications, ensuring customer satisfaction and contributing to the advancement of engine technology.

Cummins Breather Tube 4019922 in Engine Applications

The Cummins Breather Tube part number 4019922 is a critical component in the engine systems it is designed to fit. This part is engineered to ensure the proper ventilation and pressure management within the engine’s crankcase. It is essential for maintaining the engine’s health by allowing the escape of gases and preventing the build-up of harmful pressure.

Engine Compatibility

The Breather Tube 4019922 is compatible with several Cummins engine models, including but not limited to:

- 6C8.3: This engine model benefits from the breather tube’s role in managing crankcase pressure, ensuring optimal engine performance and longevity.

Functionality in Engine Systems

In the context of the 6C8.3 engine, the breather tube connects the crankcase to the intake manifold or the air filter housing. This connection allows for the controlled release of gases that are produced during the engine’s operation. By doing so, it prevents the accumulation of pressure that could otherwise lead to leaks, gasket failures, or other mechanical issues.

The breather tube is designed to route these gases back into the intake system, where they can be safely burned off. This process not only maintains the integrity of the engine’s sealing components but also contributes to the overall efficiency of the engine by reducing the amount of unburned hydrocarbons released into the environment.

Importance of Proper Installation

Proper installation of the breather tube is crucial for the engine’s performance. Any obstruction or misalignment in the tube can lead to increased crankcase pressure, which may result in oil leaks, gasket failures, and other mechanical problems. Ensuring that the breather tube is correctly installed and functioning as intended is a key aspect of maintaining the engine’s reliability and efficiency.

Maintenance and Replacement

Regular inspection of the breather tube is recommended as part of routine engine maintenance. Over time, the tube may become clogged with debris or develop leaks due to wear and tear. If any issues are detected, it is important to replace the breather tube with a genuine Cummins part to ensure compatibility and performance. Using non-genuine parts can lead to improper function and potential engine damage.

Role of Part 4019922 Breather Tube in Engine Systems

The part 4019922 Breather Tube is an essential component in managing the crankcase ventilation system within an engine. It facilitates the release of gases that accumulate within the crankcase, ensuring that the internal pressure remains balanced. This is particularly important in preventing the buildup of harmful gases, such as unburned fuel and combustion byproducts, which can lead to increased wear on engine components.

In the crankcase breather system, the Breather Tube connects to the crankcase and routes the expelled gases to a safe location, often the intake manifold. This allows the gases to be reintroduced into the combustion process, enhancing fuel efficiency and reducing emissions. The Breather Tube works in conjunction with the Positive Crankcase Ventilation (PCV) valve, which regulates the flow of these gases based on engine load and RPM.

Effective operation of the Breather Tube is vital for maintaining optimal engine performance. It helps in keeping the crankcase clean by preventing the accumulation of sludge and moisture, which can form from condensed combustion gases. This, in turn, protects critical engine components, such as the crankshaft and bearings, from premature wear.

Additionally, the Breather Tube plays a role in reducing the emission of hydrocarbons into the atmosphere. By ensuring that crankcase gases are properly ventilated and recirculated, it contributes to a more environmentally friendly engine operation.

Conclusion

The Cummins 4019922 Breather Tube is a key element in the crankcase ventilation system, promoting engine efficiency, longevity, and environmental compliance. Its proper installation, maintenance, and replacement are essential for ensuring the optimal performance and reliability of heavy-duty truck engines.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ -

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.