This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

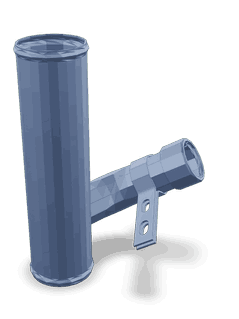

The Cummins 4100767 Breather Tube is a component designed for use in commercial trucks. It serves a specific function within the engine system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and operation is key to maintaining the health and performance of the truck’s engine.

Basic Concepts of Breather Tubes

Breather tubes are components found in engine systems that allow for the release of pressure and the escape of moisture and contaminants from the crankcase 1. They play a role in maintaining a balanced pressure environment within the engine, which is vital for optimal engine operation. By facilitating the removal of excess pressure and moisture, breather tubes help prevent the buildup of harmful substances that could lead to engine wear or failure 2.

Purpose of the Cummins 4100767 Breather Tube

The Cummins 4100767 Breather Tube is designed to perform pressure equalization and moisture prevention within the truck’s engine system. It allows for the venting of gases and vapors from the crankcase, which helps maintain a stable internal pressure. Additionally, it aids in preventing moisture accumulation, which can lead to corrosion and other forms of engine damage.

Key Features

The Cummins 4100767 Breather Tube is constructed from durable materials that are resistant to the harsh conditions within an engine environment. Its design includes features that enhance its functionality, such as a filtration system to trap contaminants before they can enter the engine’s air intake. This breather tube may also incorporate unique attributes that set it apart from other models, such as an enhanced sealing mechanism to ensure a tight fit and prevent leaks.

Benefits

The use of the Cummins 4100767 Breather Tube can lead to improved engine performance, as it helps maintain a clean and dry crankcase environment. This can contribute to the longevity of the engine by reducing the risk of wear and corrosion. Additionally, the reliable operation of the breather tube ensures consistent engine performance, which is crucial for the demanding applications of commercial trucks.

Installation and Compatibility

Proper installation of the Cummins 4100767 Breather Tube is important to ensure it functions as intended. Installation procedures should follow manufacturer guidelines to avoid common pitfalls that could lead to reduced effectiveness or damage to the engine. Compatibility with specific truck models and engine types should be verified to ensure optimal performance and integration within the engine system.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4100767 Breather Tube is recommended to ensure its continued optimal functioning. This may include periodic inspections for signs of wear or damage, as well as cleaning or replacing the filter element as needed. Troubleshooting common issues, such as leaks or reduced airflow, can often be addressed through proper maintenance practices or, if necessary, replacement of the breather tube.

Common Failures and Solutions

Breather tubes can experience failures such as clogging, leaks, or structural damage. These issues can often be identified through routine inspections and addressed through cleaning, repair, or replacement. It is important to follow manufacturer recommendations for maintenance and replacement to ensure the breather tube continues to perform its intended function effectively.

Environmental and Operational Considerations

The performance of the Cummins 4100767 Breather Tube can be influenced by environmental factors such as temperature extremes and the presence of contaminants in the air. Operational considerations, such as the type of truck usage (e.g., long-haul vs. urban delivery), can also impact the breather tube’s effectiveness. Understanding these factors can help in making informed decisions about maintenance and replacement schedules.

Manufacturer Information - Cummins

Cummins is a well-established manufacturer with a reputation for quality and innovation in the automotive components industry. Their history of producing reliable and high-performance parts is a testament to their commitment to excellence. The Cummins 4100767 Breather Tube is a product of this dedication, designed to meet the rigorous demands of commercial truck engines.

Role of Part 4100767 Breather Tube in Engine Systems

The 4100767 Breather Tube is an essential component in maintaining the health and efficiency of various engine systems. It is specifically designed to manage the pressure within the crankcase by allowing air and gases to escape, thus preventing a buildup that could lead to engine damage.

Integration with the Crankcase

The breather tube is directly connected to the crankcase, where it plays a significant role in venting out gases produced during the combustion process. These gases, if not properly managed, can increase pressure within the crankcase, leading to oil leaks and reduced engine performance. The breather tube ensures that the crankcase remains at an optimal pressure, thereby enhancing the engine’s longevity and efficiency.

Connection to the Cover and Hand Hole

In many engine designs, the breather tube is routed through the engine cover and hand hole areas. This routing not only protects the tube from external damage but also ensures that the gases are directed away from sensitive components. The hand hole, often used for maintenance access, benefits from the breather tube’s presence as it helps in keeping the area free from excess pressure and contaminants.

Interaction with the Electronic Control Module Kit and Engine Harness Kit

Modern engines are equipped with electronic control module (ECM) kits and engine harness kits that monitor and regulate various engine functions. The breather tube indirectly supports these systems by maintaining a stable crankcase environment. A well-ventilated crankcase ensures that the ECM and engine harness operate under consistent conditions, which is vital for accurate sensor readings and efficient engine management.

Importance in Hand Hole Cover Applications

The hand hole cover is another area where the breather tube’s role is significant. By ensuring that pressure is relieved from the crankcase, the breather tube helps in maintaining the integrity of the hand hole cover. This is particularly important during engine maintenance, where the hand hole cover is frequently accessed. A pressure-free environment around the hand hole cover simplifies the maintenance process and reduces the risk of cover damage.

Conclusion

In summary, the Cummins 4100767 Breather Tube is a vital component that enhances the functionality and reliability of engine systems by effectively managing crankcase pressure and ensuring a clean, stable environment for other critical engine components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.