This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

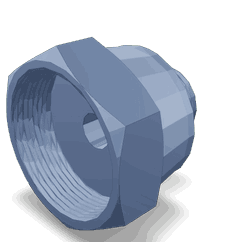

The Tube Fitting Reducer 4302984, a component manufactured by Cummins, is designed for use in commercial trucks. It plays a role in managing fluid systems, ensuring the efficient operation of various truck systems 1.

Basic Concepts of Tube Fitting Reducers

A tube fitting reducer is a device used in fluid systems to connect tubes of different diameters. It facilitates the transition between larger and smaller tubes, ensuring a smooth flow of fluids. The design typically includes conically tapered sections that allow for a gradual reduction in diameter, minimizing turbulence and pressure loss in the fluid flow 2.

Purpose of the 4302984 Tube Fitting Reducer

This Cummins part is specifically designed to integrate into the fluid systems of commercial trucks. It is part of systems that require the transfer of fluids between components of varying sizes. By accommodating different tube diameters, it ensures a consistent and efficient flow, which is vital for the operation of the truck’s systems. This reducer manages fluids such as coolant, fuel, and hydraulic fluids, contributing to the overall performance and reliability of the truck 3.

Key Features

The 4302984 is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring long-term reliability. The reducer features precise connection types that ensure a secure fit with other system components. Its design specifications are tailored to meet the demanding conditions of commercial truck operations, providing a robust solution for fluid management 4.

Benefits

Utilizing this part offers several advantages. It enhances the efficiency of fluid transfer within the truck’s systems, contributing to optimal performance. Its durable construction ensures longevity, reducing the need for frequent replacements. Additionally, its design allows for compatibility with a wide range of system components, facilitating easy integration into existing systems.

Installation Considerations

When installing the Tube Fitting Reducer, it is important to follow guidelines and best practices to ensure a proper fit and seal. Necessary tools and preparation steps should be undertaken to facilitate a smooth installation process. Ensuring the reducer is correctly aligned and securely fastened will help prevent leaks and ensure efficient fluid flow.

Troubleshooting Common Issues

Common issues associated with tube fitting reducers include leaks and blockages. To address these problems, it is important to conduct a thorough inspection of the reducer and its connections. Identifying the source of a leak or blockage allows for targeted troubleshooting steps, such as tightening connections or cleaning out debris, to resolve the issue effectively.

Maintenance Tips

Regular maintenance of the 4302984 is recommended to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear or damage and cleaning procedures to remove any buildup that could impede fluid flow. Adhering to recommended inspection intervals and maintenance practices will help maintain the reducer’s efficiency and reliability.

Cummins Overview

Cummins is a renowned manufacturer in the commercial truck industry, with a history of producing high-quality components and systems. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the rigorous demands of commercial trucking. Cummins’ reputation for quality and reliability makes them a preferred choice among truck manufacturers and operators.

Role of Part 4302984 Tube Fitting Reducer in Engine Systems

Integration with the Pump

In pump systems, the Tube Fitting Reducer ensures seamless transitions between different diameters of tubing. This is particularly important in high-pressure environments where consistent flow rates and minimal pressure drops are essential. By reducing the diameter of the tubing at specific points, the reducer helps maintain the integrity of the fluid dynamics within the pump system. This results in enhanced operational efficiency and reduced wear on pump components.

Function in Lubricating Oil Systems

Within lubricating oil systems, the Tube Fitting Reducer plays a significant role in managing the flow of oil to various engine components. It facilitates the transition from larger supply lines to smaller delivery lines, ensuring that oil reaches critical engine parts such as bearings, pistons, and camshafts without interruption. The reducer helps in maintaining consistent oil pressure and flow rates, which are vital for effective lubrication and cooling of engine components. This, in turn, contributes to the longevity and reliability of the engine.

Overall Impact on Engine Systems

The incorporation of the Tube Fitting Reducer in these systems allows for more precise control over fluid dynamics. It enables engineers and mechanics to design more efficient and reliable engine systems by ensuring that fluids are delivered at the correct pressure and flow rate to where they are needed most. This component is a testament to the importance of meticulous engineering in achieving optimal engine performance.

Conclusion

The Tube Fitting Reducer 4302984 by Cummins is a critical component in the efficient management of fluid systems in commercial trucks. Its design and features ensure compatibility, efficient fluid transfer, and long-term reliability. Proper installation, maintenance, and troubleshooting are essential to maximize its benefits and ensure the optimal performance of the truck’s systems.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Awari, G. K., Kumbhar, V. S., & Tirpude, R. B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.