This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

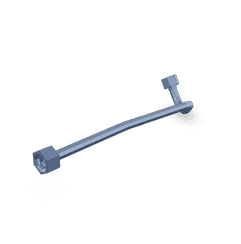

The Scavenging Outlet Tube, identified by part number 4314286, is a component manufactured by Cummins, a prominent entity in the automotive and heavy-duty truck industry. This tube is instrumental in the operation of heavy-duty truck engines, contributing to their efficiency and performance. Cummins, renowned for its commitment to innovation and quality, designs this part to meet the demanding requirements of modern diesel engines.

Basic Concepts

In diesel engines, the scavenging process is vital for maintaining engine efficiency and performance. Scavenging involves the removal of exhaust gases from the cylinder to make room for fresh air intake, which is crucial for the combustion process. The Scavenging Outlet Tube is integral to this process. It facilitates the efficient expulsion of exhaust gases from the engine, ensuring that the cylinder is adequately prepared for the next combustion cycle. This contributes to the overall efficiency and performance of the engine by optimizing the air-fuel mixture and reducing the likelihood of incomplete combustion 1.

Purpose and Function

The Scavenging Outlet Tube serves a specific role in the operation of a truck engine. It is involved in the scavenging process, where it aids in the management of exhaust gases. By providing a pathway for these gases to exit the engine, the tube helps maintain a clean combustion chamber. This not only enhances engine efficiency but also plays a part in managing exhaust emissions, contributing to a more environmentally friendly operation 2.

Key Features

The design of the Scavenging Outlet Tube incorporates several features that enhance its performance and durability. Constructed from high-quality materials, it is built to withstand the high temperatures and pressures characteristic of diesel engine environments. Its design ensures a secure fit within the engine system, minimizing the risk of leaks and ensuring efficient gas flow. These features contribute to the tube’s reliability and longevity, making it a valuable component in heavy-duty truck engines.

Benefits

The incorporation of the Scavenging Outlet Tube into heavy-duty truck engines offers several advantages. It contributes to improved engine efficiency by ensuring a clean combustion chamber and optimizing the air-fuel mixture. Additionally, by facilitating the efficient removal of exhaust gases, it plays a role in reducing emissions, aligning with environmental regulations. The tube’s durable construction also enhances the overall reliability and performance of the engine, providing long-term value to truck operators 3.

Installation and Compatibility

Proper installation of the Scavenging Outlet Tube is crucial for ensuring its effective operation within the engine system. Installation procedures may vary slightly depending on the specific truck model, highlighting the importance of following manufacturer guidelines. Ensuring a secure and correct fit is essential for maintaining engine efficiency and preventing potential issues related to exhaust gas management.

Maintenance and Troubleshooting

Routine maintenance of the Scavenging Outlet Tube is important for ensuring its continued performance and durability. Regular inspections can help identify any signs of wear or damage, allowing for timely repairs or replacements. Common issues may include blockages or leaks, which can affect engine efficiency and emissions. Troubleshooting these issues promptly can help maintain optimal engine performance and prevent more significant problems down the line.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. Its commitment to advancing technology and meeting the needs of its customers underscores its position as a leader in the field of engine manufacturing and component design.

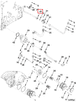

Scavenging Outlet Tube (Part 4314286) Compatibility with Cummins Engines

The Scavenging Outlet Tube, identified by the part number 4314286, is a critical component in Cummins engines, facilitating the removal of exhaust gases from the combustion chamber. This part is integral to the engine’s scavenging process, ensuring efficient operation and performance.

QSK19 Engine

The QSK19 engine, known for its robust design and high power output, integrates the Scavenging Outlet Tube to maintain optimal scavenging efficiency. This engine is typically used in marine and stationary power applications, where reliability and performance are paramount.

CM2350 Engine

The CM2350 engine, another high-performance model from Cummins, also utilizes the Scavenging Outlet Tube. This engine is designed for heavy-duty applications, providing the necessary power and durability for demanding environments. The Scavenging Outlet Tube in the CM2350 ensures that exhaust gases are effectively removed, contributing to the engine’s overall efficiency and longevity.

K105 Engine

The K105 engine, part of Cummins’ lineup of industrial and power generation engines, incorporates the Scavenging Outlet Tube to enhance its scavenging process. This engine is widely used in various industrial applications, where consistent performance and reliability are essential. The Scavenging Outlet Tube in the K105 plays a crucial role in maintaining the engine’s efficiency and reducing emissions.

Grouping of Engines

The Scavenging Outlet Tube (Part 4314286) is compatible with the QSK19, CM2350, and K105 engines, all of which benefit from its role in the scavenging process. These engines, while differing in specific applications and power outputs, share the commonality of requiring efficient exhaust gas removal to maintain optimal performance and reliability.

Role of Part 4314286 Scavenging Outlet Tube in Engine Systems

The Scavenging Outlet Tube, part 4314286, is integral to the efficient operation of various engine systems, particularly in the context of pumps and lubricating oil management.

In pump systems, the Scavenging Outlet Tube facilitates the removal of unwanted gases and impurities from the pump cavity. This ensures that the pump operates with optimal efficiency and longevity. By effectively scavenging these contaminants, the tube helps maintain the pump’s performance and reliability, reducing the likelihood of wear and tear on internal components.

Regarding lubricating oil systems, the Scavenging Outlet Tube plays a significant role in preserving the quality of the oil. It aids in the removal of air and other impurities that may accumulate within the oil reservoir. This process is essential for maintaining the viscosity and lubricating properties of the oil, which are vital for the smooth operation of engine components. Clean, well-maintained oil ensures that moving parts are adequately lubricated, minimizing friction and heat generation, and thereby enhancing the overall efficiency and durability of the engine.

Conclusion

The Scavenging Outlet Tube, part 4314286, is a critical component in the operation of heavy-duty truck engines, particularly those manufactured by Cummins. Its role in the scavenging process ensures efficient removal of exhaust gases, contributing to engine efficiency, performance, and environmental compliance. The tube’s durable construction and compatibility with various Cummins engines make it a valuable asset in maintaining optimal engine operation. Regular maintenance and proper installation are essential for maximizing the benefits of this Cummins part.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

Injection Technologies: Mixture Formation Strategies, Alessandro Ferrari and Pietro Pizzo, SAE International, 2022

↩ -

Automotive Transmissions Fundamentals Selection Design and Application, Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Springer Vieweg, 2011

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.