This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

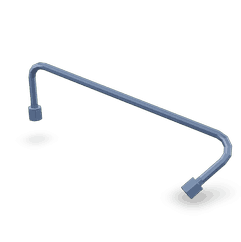

The Cummins 4350852 Pressure Sensing Tube is a component designed for use in commercial trucks. Its purpose is to facilitate the accurate measurement of pressure within the vehicle’s systems. This part contributes to the overall efficiency and reliability of truck operations by ensuring that pressure levels are monitored and maintained within optimal ranges 1.

Basic Concepts of Pressure Sensing Tubes

A pressure sensing tube is a conduit that allows for the transmission of pressure from a specific point in a system to a pressure sensor or gauge. Within a vehicle’s systems, these tubes play a role in conveying pressure information, which is then used by the vehicle’s electronic control units to make adjustments and ensure proper operation. The principles of pressure sensing technology involve the detection and measurement of force per unit area exerted by a fluid, which in the context of trucks, can include air, fuel, or hydraulic fluids 2.

Purpose and Role in Truck Operation

The 4350852 Pressure Sensing Tube is integral to the operation of a truck as it provides data that is crucial for the management of various systems. It is connected to sensors that monitor pressure levels in components such as the fuel system, brake system, or turbocharger. The data from the pressure sensing tube allows the truck’s electronic control system to make real-time adjustments, ensuring that the truck operates efficiently and safely 3.

Key Features

The Cummins 4350852 Pressure Sensing Tube is characterized by several key features. It is constructed from materials that are resistant to the high temperatures and pressures found in truck engines. The design of the tube includes features that ensure a secure connection to both the pressure source and the sensor, minimizing the risk of leaks. Technological advancements in the tube’s material and design contribute to its durability and accuracy in pressure measurement.

Benefits

The use of the 4350852 Pressure Sensing Tube in truck operations offers several benefits. It contributes to improved performance by ensuring that systems operate within their designed pressure parameters. This can lead to enhanced fuel efficiency and reduced wear on components. The reliability of the tube ensures that pressure data is consistently accurate, which is vital for the safe operation of the truck. Additionally, the efficiency gained from proper pressure management can result in cost savings over time.

Installation Process

Installing the Cummins 4350852 Pressure Sensing Tube requires attention to detail to ensure proper function. The process involves identifying the correct location for the tube within the truck’s system, using the appropriate tools to connect it securely, and verifying that there are no leaks after installation. Best practices include following the manufacturer’s guidelines for torque specifications and ensuring that all connections are tight and free from contaminants.

Common Issues and Troubleshooting

Issues with the 4350852 Pressure Sensing Tube may include leaks, inaccurate readings, or physical damage to the tube. Troubleshooting these problems involves checking all connections for tightness, inspecting the tube for signs of wear or damage, and verifying that the sensor is functioning correctly. Solutions may range from tightening connections to replacing the tube if it is damaged.

Maintenance Tips

Regular maintenance of the Cummins 4350852 Pressure Sensing Tube is important for ensuring optimal performance and longevity. This includes periodic inspection of the tube and connections for signs of wear or damage, cleaning the tube to remove any contaminants, and verifying that the sensor is calibrated correctly. Adhering to a maintenance schedule can help prevent issues and ensure that the truck operates efficiently.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation, Cummins has a diverse product range that serves various industries, including commercial trucking. The company is committed to advancing technology and providing reliable solutions that meet the needs of its customers.

Pressure Sensing Tube 4350852 in Cummins Engines

The Pressure Sensing Tube 4350852, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the engine’s operation, ensuring that pressure readings are accurate and reliable.

QSK50 and CM2150 Engines

In the QSK50 and CM2150 engines, the Pressure Sensing Tube 4350852 plays a pivotal role in the engine’s fuel injection system. It is designed to monitor the pressure within the fuel system, providing essential data to the engine control unit (ECU). This data is crucial for maintaining optimal fuel injection timing and pressure, which directly impacts engine performance and efficiency.

MCRS Engines

For the MCRS engines, the Pressure Sensing Tube 4350852 is similarly vital. It ensures that the engine’s fuel system operates within the specified pressure parameters. This component is engineered to withstand the high-stress environment of the engine, providing consistent and accurate pressure readings over time.

Integration and Functionality

The Pressure Sensing Tube 4350852 is integrated into the engine’s fuel system, where it interfaces with the fuel rail or other pressure-sensitive components. Its design allows it to accurately measure the pressure of the fuel as it is delivered to the injectors. This information is then relayed to the ECU, which adjusts the fuel injection parameters accordingly to ensure the engine runs smoothly and efficiently.

Importance in Engine Performance

The accurate functioning of the Pressure Sensing Tube 4350852 is crucial for maintaining the engine’s performance. Any deviation in the pressure readings can lead to suboptimal fuel injection, which can result in reduced engine efficiency, increased emissions, and potential engine damage over time. Therefore, this component is subject to rigorous quality control and testing to ensure it meets Cummins’ high standards.

Role of Part 4350852 Pressure Sensing Tube in Engine Systems

The Part 4350852 Pressure Sensing Tube is integral to the efficient operation of various engine components. Its primary function is to accurately measure and relay pressure data, ensuring optimal performance and safety of the engine system.

Integration with the Arrangement

In the engine’s arrangement, the Pressure Sensing Tube is strategically positioned to monitor pressure levels within the system. It works in conjunction with sensors and control units to provide real-time data, allowing for precise adjustments and maintaining the desired pressure levels throughout the engine’s operation.

Collaboration with the Pressure Regulator Valve

The Pressure Sensing Tube plays a significant role when integrated with the Pressure Regulator Valve. By continuously providing pressure readings, it enables the valve to make necessary adjustments. This ensures that the fuel and air mixture remains within the optimal range, enhancing combustion efficiency and reducing the risk of engine damage due to inconsistent pressure levels.

Function within the Fuel Transfer Kit

In the Fuel Transfer Kit, the Pressure Sensing Tube is essential for maintaining the correct pressure during fuel transfer. It helps in detecting any anomalies in pressure, which could indicate a blockage or leak in the fuel lines. This early detection allows for timely intervention, preventing potential fuel system failures and ensuring a consistent fuel supply to the engine.

Importance in the Service Kit

When included in the Service Kit, the Pressure Sensing Tube aids in the routine maintenance and inspection of the engine. It allows mechanics to monitor pressure changes over time, identifying wear and tear or inefficiencies in the system. This proactive approach helps in scheduling maintenance tasks, thereby extending the lifespan of the engine and enhancing its reliability.

Conclusion

The Cummins 4350852 Pressure Sensing Tube is a vital component in the operation of commercial trucks and Cummins engines. Its role in accurately measuring and relaying pressure data ensures the optimal performance, safety, and efficiency of the engine system. Regular maintenance and proper installation are crucial to maximize the benefits of this part and ensure the longevity and reliability of the engine.

-

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.