4376257

Tube Kit

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4376257 Tube Kit is a specialized component designed for use in commercial trucks. Its primary role is to facilitate the efficient transfer of fluids within the truck’s system. A tube kit, in general, consists of a set of tubes and fittings that connect various parts of a vehicle’s fluid systems, ensuring smooth operation and reliability. In the automotive industry, tube kits are commonly used to replace worn or damaged sections of fluid lines, enhancing system performance and longevity 1.

Purpose and Function

This Cummins part is specifically engineered to integrate seamlessly with a truck’s existing fluid system. It operates by providing a direct and secure pathway for fluids such as coolant, oil, or hydraulic fluid. This kit ensures that fluids are transported efficiently between components, which is vital for maintaining optimal engine performance and system reliability. By replacing or augmenting the original fluid lines, the tube kit helps to prevent leaks, reduce the risk of system failure, and enhance overall truck operation 3.

Key Features

The Cummins 4376257 Tube Kit boasts several key features that set it apart from other tube kits. It is constructed from high-quality materials, ensuring durability and resistance to corrosion. The design includes precision-machined fittings and robust tubing, which are engineered to withstand the high pressures and temperatures encountered in commercial truck applications. Additionally, the kit may feature unique attributes such as reinforced joints or specialized coatings that further enhance its performance and longevity 2.

Benefits

Installing the Cummins 4376257 Tube Kit offers several benefits. Improved durability is one of the primary advantages, as the high-quality materials and precise engineering contribute to a longer service life. Enhanced performance is another benefit, as the efficient fluid transfer facilitated by the tube kit can lead to better engine operation and system reliability. Over time, the increased durability and performance can result in potential cost savings by reducing the frequency of repairs and maintenance. These benefits collectively contribute to overall truck efficiency and reliability 4.

Installation Process

Installing the Cummins 4376257 Tube Kit requires careful attention to detail and adherence to safety protocols. The process typically involves disconnecting the old fluid lines, ensuring the system is clean and free of debris, and then fitting the new tube kit into place. Specific tools such as wrenches, torque wrenches, and possibly a flaring tool may be required. Safety precautions include wearing appropriate personal protective equipment (PPE) and ensuring the truck’s engine is off and cool before beginning the installation. Following the manufacturer’s instructions ensures a proper and secure installation 3.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4376257 Tube Kit is important to ensure its longevity and optimal performance. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the tube kit and its connections as part of routine maintenance can prevent buildup and ensure efficient fluid transfer. Common issues that may arise include leaks at connection points or corrosion within the tubes. Troubleshooting steps may involve tightening connections, replacing damaged sections, or, in severe cases, replacing the entire kit. Adhering to a maintenance schedule helps to identify and address issues before they lead to system failure 2.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to excellence is evident in its extensive product range and continuous investment in research and development. Cummins’ dedication to providing high-quality components ensures that their products, like the 4376257 Tube Kit, meet the demanding requirements of commercial truck applications 3.

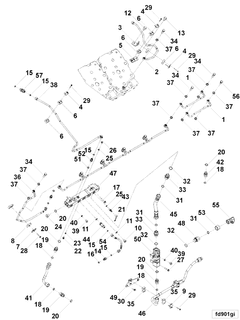

Components of Cummins Tube Kit 4376257

The Cummins Tube Kit 4376257 is designed to ensure optimal performance and reliability in various applications. This kit comprises several critical components, each playing a specific role in the overall functionality of the system.

Sealing Washer (4323977)

The sealing washer (4323977) is a critical component within the Tube Kit. Its primary function is to provide a secure and leak-proof seal between different parts of the tube assembly. This washer is typically positioned at connection points to prevent any fluid leakage, ensuring that the system maintains pressure integrity and operates efficiently. The use of a high-quality sealing washer is crucial for the longevity and performance of the tube kit, as it helps in withstanding high pressures and varying temperatures commonly encountered in such applications 3.

Fuel Drain Tube (2887330)

The fuel drain tube (2887330) serves a vital role in the Tube Kit by facilitating the safe and efficient drainage of fuel from the system. This component is designed to allow for the removal of fuel during maintenance procedures or in the event of a system malfunction. The fuel drain tube ensures that fuel can be expelled without causing spills or contamination, thereby enhancing safety and simplifying the maintenance process. Its inclusion in the kit underscores the importance of having a reliable method for fuel evacuation, which is critical for both operational safety and system integrity 4.

Conclusion

The Cummins 4376257 Tube Kit is an essential component for maintaining the efficiency and reliability of fluid systems in commercial trucks. Its high-quality construction, precise engineering, and comprehensive design ensure optimal performance and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to overall truck efficiency and reliability.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ ↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ ↩ ↩ ↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ ↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Sealing Washer | 6 | 4323977 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.