4385848

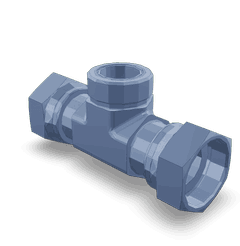

Tube Connector Tee

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tube Connector Tee (Part #4385848) manufactured by Cummins is a component designed for use in commercial truck systems. It plays a role in maintaining efficient operations by facilitating the proper distribution and management of fluids within the truck’s system. This part is integral to ensuring that the various fluid-based systems in a truck operate smoothly and effectively.

Basic Concepts and Functionality

A Tube Connector Tee is a fitting that allows for the connection of three tubes or pipes at a 90-degree angle. It operates on the principles of fluid dynamics, enabling the efficient distribution of fluids by merging or splitting fluid flow paths. This design ensures that fluids can be directed to multiple locations or combined from different sources within the truck’s system, optimizing the flow and pressure of the fluids involved 1.

Purpose of the Tube Connector Tee in Truck Operations

The Tube Connector Tee serves a specific role in the operation of a truck by aiding in the distribution and management of fluids. It allows for the connection of multiple fluid lines, which is particularly useful in systems where fluids need to be routed to different components or where multiple fluid sources need to be combined. This part ensures that the truck’s fluid systems operate efficiently, contributing to the overall performance and reliability of the vehicle.

Key Features

The Tube Connector Tee is characterized by several key features that enhance its performance and durability. It is typically made from high-quality materials that are resistant to corrosion and wear, ensuring long-lasting use in demanding environments. The design of the Tube Connector Tee includes precise threading and sealing surfaces to ensure a secure and leak-free connection. Additionally, it may feature unique attributes such as reinforced walls or specialized coatings to further improve its resistance to pressure and environmental factors.

Benefits of Using the Tube Connector Tee

Incorporating the Tube Connector Tee into truck systems offers several advantages. It contributes to the efficiency of fluid distribution, ensuring that fluids reach their intended destinations without unnecessary delays or restrictions. The reliability of the Tube Connector Tee means that it can be trusted to perform under a wide range of conditions, reducing the likelihood of system failures. Furthermore, its design allows for ease of maintenance, making it simpler to inspect, repair, or replace when necessary.

Installation and Integration

Proper installation and integration of the Tube Connector Tee within a truck’s system are important for optimal performance. It should be placed in a location that allows for easy access for maintenance and ensures that it is securely connected to the fluid lines it is intended to join. Correct placement and connection are vital to prevent leaks and ensure that the fluid dynamics within the system are not adversely affected.

Troubleshooting and Maintenance

Common issues with the Tube Connector Tee may include leaks, blockages, or corrosion. Troubleshooting steps involve inspecting the connections for tightness, checking for signs of wear or damage, and ensuring that the fluid lines are free from obstructions. Regular maintenance, such as cleaning and inspecting the Tube Connector Tee for signs of wear, can help ensure its longevity and consistent performance.

Compatibility and Usage

The Tube Connector Tee is designed for use in specific types of trucks and systems. It is important to follow any specific usage guidelines or recommendations provided by Cummins to ensure compatibility and optimal performance. These guidelines may include information on the types of fluids it is designed to handle, pressure ratings, and any special installation considerations.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories worldwide. The company’s product range includes solutions for on-highway, off-highway, and stationary applications, demonstrating its versatility and expertise in the automotive industry 2.

Role of Part 4385848 Tube Connector Tee in Engine Systems

The Tube Connector Tee part 4385848 is an essential component in the efficient operation of various engine systems. Its primary function is to facilitate the merging or splitting of fluid pathways, ensuring seamless integration and operation within the engine’s fluid dynamics.

Integration with the Air Induction System (AID)

In the Air Induction System (AID), the Tube Connector Tee plays a significant role by allowing the combination of air streams from different sources before they enter the engine’s intake manifold. This ensures a consistent and optimized air-fuel mixture, which is vital for combustion efficiency and overall engine performance.

Function within the Coolant System

Within the coolant system, the Tube Connector Tee is instrumental in managing the flow of coolant to various engine components. It enables the coolant to be distributed evenly, ensuring that all parts of the engine, such as the cylinder head, block, and other critical areas, receive adequate cooling. This helps in maintaining optimal engine temperature and preventing overheating.

Role in the Heater System

In the heater system, the Tube Connector Tee is used to direct the flow of hot coolant from the engine to the heater core. This ensures that the cabin heating system operates efficiently, providing comfortable temperatures for occupants regardless of external conditions.

Application in the Starting System

Although the starting system primarily involves electrical components, the Tube Connector Tee can be indirectly beneficial. By ensuring the engine operates at optimal temperatures and conditions, it supports the starting system’s efficiency. A well-maintained engine, with proper fluid dynamics managed by components like the Tube Connector Tee, starts more reliably and performs better overall.

Conclusion

The Tube Connector Tee part 4385848, manufactured by Cummins, is a versatile and essential component in the operation of various truck and engine systems. Its role in facilitating the efficient distribution and management of fluids contributes significantly to the overall performance and reliability of the vehicle. Proper installation, maintenance, and adherence to Cummins’ guidelines ensure optimal performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.