This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

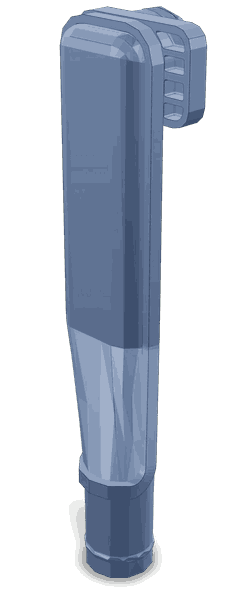

The Cummins 4897534 Breather Tube is a component designed for use in commercial trucks. It serves a specific function within the engine system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and operation is key to maintaining the performance of commercial trucks.

Basic Concepts of Breather Tubes

A breather tube is an integral part of an engine’s ventilation system. It allows for the release of gases and vapors that accumulate within the engine compartment. This process helps maintain pressure equilibrium, preventing the buildup of harmful gases that could otherwise affect engine performance. The breather tube operates on the principle of allowing air to enter and exit the engine compartment as needed, ensuring a stable environment for engine components 1.

Purpose of the Cummins 4897534 Breather Tube

The Cummins 4897534 Breather Tube plays a role in the operation of a truck by facilitating the release of gases from the engine compartment. This function is vital for maintaining pressure equilibrium, which is necessary for the proper operation of engine components. By allowing gases to escape, the breather tube helps prevent the buildup of pressure that could lead to engine damage 2.

Key Features

The Cummins 4897534 Breather Tube is designed with specific features that enhance its performance and durability. These include a robust construction that can withstand the harsh conditions of commercial truck operation, as well as a design that ensures efficient gas release. The tube is also engineered to be compatible with Cummins engines, ensuring seamless integration into the engine system.

Benefits of Using the Cummins 4897534 Breather Tube

Using the Cummins 4897534 Breather Tube offers several advantages. It contributes to improved engine performance by maintaining a stable environment within the engine compartment. This can lead to increased longevity and reliability of the engine, as well as potentially improved fuel efficiency. The breather tube is also designed to be durable, reducing the need for frequent replacements 3.

Installation Considerations

Proper installation of the Cummins 4897534 Breather Tube is important for ensuring optimal functionality and safety. It should be installed according to the manufacturer’s guidelines, with attention paid to securing it in place and ensuring it is properly connected to the engine system. Regular checks should be performed to ensure the tube remains in good condition and is functioning as intended.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 4897534 Breather Tube involves checking for signs of wear or damage, and ensuring it is free from obstructions. If issues are detected, such as a blockage or leak, these should be addressed promptly to prevent further problems. Troubleshooting may involve inspecting the tube for physical damage, checking connections for leaks, and ensuring the tube is properly positioned.

Common Failure Modes

Breather tubes can experience several types of failure, including blockages, leaks, and physical damage. Symptoms of failure may include unusual engine noises, reduced performance, or visible damage to the tube. Preventive measures include regular maintenance checks, ensuring the tube is properly installed, and addressing any issues promptly.

Impact on Engine Performance

The breather tube plays a role in overall engine performance by helping to maintain a stable environment within the engine compartment. This can affect fuel efficiency, power output, and emissions. A well-functioning breather tube ensures that gases are released efficiently, contributing to the engine’s ability to operate at its best 4.

Cummins Company Overview

Cummins Inc. is a well-established company with a strong reputation in the commercial truck industry. It has a history of innovation and quality, contributing significantly to the development of reliable and efficient engine components. The company’s commitment to excellence is reflected in its products, including the Cummins 4897534 Breather Tube.

Cummins Engine Breather Tube Part 4897534

The Cummins Breather Tube part number 4897534 is a critical component designed to fit seamlessly with several Cummins engine models. This part is essential for maintaining the engine’s operational integrity by managing the pressure within the crankcase.

ISB CM850 and ISBE CM800 Engines

The ISB CM850 and ISBE CM800 engines are part of Cummins’ robust lineup, known for their reliability and performance in various applications. The Breather Tube part 4897534 is engineered to fit these engines, ensuring that the crankcase pressure is balanced and regulated. This helps in preventing the build-up of harmful gases and moisture that can compromise engine performance and longevity.

Installation and Functionality

When installed, the Breather Tube part 4897534 connects to the crankcase ventilation system, allowing excess pressure to be safely vented. This process is crucial in maintaining the engine’s efficiency and preventing potential damage from pressure build-up. The design of the tube ensures a secure fit and reliable performance across the specified engine models.

Compatibility and Usage

The Breather Tube part 4897534 is specifically designed to be compatible with the ISB CM850 and ISBE CM800 engines. Its design and material are chosen to withstand the operational conditions of these engines, ensuring durability and effectiveness over time. This part is an integral component in the maintenance and upkeep of these engines, contributing to their overall reliability and performance.

Role of Part 4897534 Breather Tube in Engine Systems

The Part 4897534 Breather Tube is an essential component in managing the ventilation of engine systems, specifically within the crankcase. Its primary function is to allow the release of gases and vapors that accumulate during engine operation.

In the crankcase, the Breather Tube facilitates the escape of gases produced by the combustion process, which includes unburnt fuel, moisture, and other byproducts. This is vital for maintaining the integrity of the crankcase environment, preventing the buildup of pressure that could lead to leaks or damage to seals and gaskets.

The Breather Tube also plays a role in the overall ventilation system of the engine, working in conjunction with other components such as the Positive Crankcase Ventilation (PCV) system. In this setup, the Breather Tube helps in directing the flow of gases from the crankcase to the intake manifold, where they can be re-burnt in the combustion chamber, thus reducing emissions and improving engine efficiency.

Furthermore, the Breather Tube contributes to the longevity of engine components by ensuring that the crankcase remains at an optimal pressure. This helps in reducing wear on moving parts and maintaining the lubrication system’s effectiveness by preventing contamination of the oil with combustion byproducts.

In summary, the Part 4897534 Breather Tube is a key player in the engine’s ventilation system, ensuring the crankcase operates within safe pressure limits, contributing to the engine’s overall performance and durability.

Conclusion

The Cummins 4897534 Breather Tube is a vital component in the maintenance and performance of commercial truck engines. Its role in managing crankcase pressure and facilitating the release of gases is crucial for engine efficiency, reliability, and longevity. Proper installation, maintenance, and understanding of its function are essential for maximizing the benefits of this Cummins part.

-

Wang, Yushu. Introduction to Engine Valvetrains. SAE International, 2007.

↩ -

Parikyan Ed, Tigran. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩ -

Department of Energy. Department of Energy Fundamentals Handbook. Department of Energy, 2015.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5659862, B6.7 CM2670 B173B.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.