This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

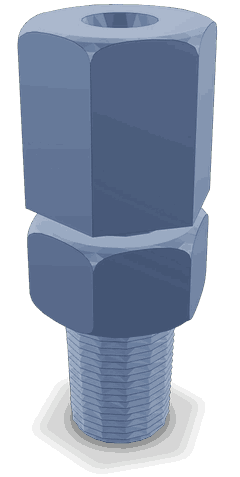

The 4914241 Tube Connector, manufactured by Cummins, is a critical component in the fluid systems of commercial trucks. Cummins, a prominent name in the commercial truck industry, produces a variety of parts aimed at enhancing the performance and reliability of truck systems. This Cummins part plays a significant role in maintaining the efficiency and functionality of a truck’s fluid systems.

Basic Concepts of Tube Connectors

Tube connectors are essential components in fluid systems, used to join tubes and other components to facilitate the flow of fluids such as coolant, fuel, or hydraulic fluid. They are designed to create secure, leak-proof connections that can withstand the pressures and temperatures typical in truck systems. Tube connectors operate by clamping or sealing the tubes together, ensuring that the fluid can move through the system without interruption 1.

Purpose of the 4914241 Tube Connector

The 4914241 Tube Connector is specifically designed to connect tubes within a truck’s fluid systems. Its role is to ensure a reliable and secure connection, allowing for the efficient transfer of fluids. This connector is part of the infrastructure that maintains the operational integrity of the truck’s systems, contributing to overall performance and safety 2.

Key Features

The 4914241 Tube Connector is engineered with several features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring longevity. The connector type allows for easy installation and removal, which is beneficial during maintenance or repairs. Additionally, unique design elements may include reinforced seals or specialized clamps that provide a tighter, more secure connection 3.

Benefits

The advantages of using the 4914241 Tube Connector include improved system efficiency due to its secure and leak-proof design. Its reliability reduces the likelihood of fluid leaks, which can lead to system failures. Furthermore, the ease of installation or replacement minimizes downtime during maintenance, contributing to the overall efficiency of truck operations.

Installation Process

Installing the 4914241 Tube Connector involves several steps to ensure a proper and secure connection. First, the tubes to be connected should be cleaned and inspected for any damage. The connector is then positioned over the tubes, and any necessary clamps or fasteners are tightened to secure the connection. Tools required may include wrenches or specialized clamping tools, depending on the specific design of the connector.

Maintenance Tips

To ensure the longevity and optimal performance of the 4914241 Tube Connector, regular maintenance practices should be followed. This includes periodic inspection for signs of wear, corrosion, or leaks. Cleaning the connector and surrounding areas can prevent the buildup of debris that may affect performance. Additionally, ensuring that all connections are tight and secure during routine checks can help maintain system integrity.

Troubleshooting Common Issues

Common issues with tube connectors, such as leaks, corrosion, or connection failures, can often be addressed through straightforward troubleshooting steps. Identifying the source of a leak may involve inspecting the connector and surrounding tubes for damage or loose connections. Corrosion can be mitigated through regular cleaning and the application of protective coatings. Connection failures may require re-tightening or replacing the connector.

Compatibility and Applications

The 4914241 Tube Connector is designed for use in specific types of trucks and fluid systems. It is important to verify compatibility with the truck model and the type of fluid system to ensure proper function and integration.

Safety Considerations

When working with the 4914241 Tube Connector, observing safety protocols is crucial. This includes handling fluids with care to avoid spills or exposure, and being aware of system pressures that may pose risks during installation or maintenance. Proper personal protective equipment should be worn, and all work should be conducted in a safe, controlled environment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation.

Tube Connector 4914241 Compatibility with Cummins Engines

The Tube Connector part number 4914241, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. This part is crucial for maintaining the integrity of the engine’s cooling system, ensuring efficient heat transfer and preventing leaks.

K38 Engines

In the K38 engine series, the Tube Connector 4914241 is specifically engineered to fit the engine’s cooling system architecture. This part ensures that coolant flows smoothly through the engine, maintaining optimal operating temperatures and preventing overheating. The connector’s precise fit and robust construction make it a reliable component in the K38 engine’s cooling system.

K50 Engines

Similarly, for the K50 engine series, the Tube Connector 4914241 is a critical component in the engine’s cooling system. Its design allows for efficient coolant flow, which is essential for the engine’s performance and longevity. The connector’s compatibility with the K50 engine ensures that it can withstand the pressures and temperatures typical of this engine series, providing a dependable solution for maintaining the engine’s cooling system integrity.

Grouping of Engines

Both the K38 and K50 engines benefit from the Tube Connector 4914241 due to its universal design features that cater to the specific needs of Cummins engines. The connector’s ability to fit multiple engine models within the same series highlights its versatility and importance in the engine’s overall cooling system. This part’s compatibility across different engine models underscores its critical role in ensuring the engine’s efficient operation and durability.

Role of Part 4914241 Tube Connector in Engine Systems

The 4914241 Tube Connector is integral to the seamless operation of various engine systems by facilitating secure and efficient connections between different components.

In the harness system, the Tube Connector ensures that the wiring remains intact and protected from external elements, thereby maintaining the integrity of the electrical connections. This is particularly important in high-vibration environments typical of engine compartments.

Within the wiring system, the Tube Connector plays a pivotal role in organizing and protecting wires that transmit vital data and power to various engine components. It helps in reducing the risk of short circuits and ensures that the wiring remains manageable and accessible for maintenance purposes.

In the panel system, the Tube Connector is used to secure wires that interface with the engine control panel. This ensures that all readings and controls are accurately transmitted, allowing for precise monitoring and adjustment of engine parameters.

For the engine instrument system, the Tube Connector is essential in linking sensors and gauges to the main engine control unit. This connection is vital for real-time data acquisition and ensures that all engine instruments provide accurate and timely information to the operator.

Overall, the 4914241 Tube Connector enhances the reliability and efficiency of engine systems by providing robust and secure connections across various components.

Conclusion

The 4914241 Tube Connector is a vital component in the fluid systems of commercial trucks, ensuring secure and efficient connections that contribute to the overall performance and safety of the vehicle. Its compatibility with Cummins engines, particularly the K38 and K50 series, underscores its importance in maintaining the integrity of the engine’s cooling system. Regular maintenance and proper installation are essential to maximize the benefits of this part, ensuring the longevity and reliability of the truck’s fluid systems.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.