This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

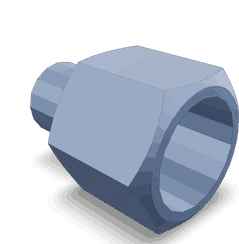

The Tube Fitting Reducer 4916566, manufactured by Cummins, is a component designed for use in commercial truck systems. This part facilitates the transition between different diameters of tubing within the fluid transfer systems of trucks, ensuring a smooth and efficient flow of fluids, which contributes to the overall performance and reliability of the vehicle 1.

Basic Concepts of Tube Fitting Reducers

Tube fitting reducers are components used in fluid systems to connect tubes of different diameters. They provide a gradual reduction in diameter, which helps to maintain the flow rate and pressure of the fluid as it moves through the system. These reducers are commonly used in various applications, including fuel, hydraulic, and coolant systems, to ensure compatibility between different components and to optimize system performance 2.

Purpose of the 4916566 Tube Fitting Reducer

The 4916566 Tube Fitting Reducer is specifically designed to facilitate the connection between tubes of varying diameters in the fluid transfer systems of trucks. It ensures that the flow of fluids remains consistent and efficient, helping to prevent leaks, reduce turbulence, and ensure that fluids are delivered to their intended destinations without interruption.

Key Features

The 4916566 Tube Fitting Reducer is characterized by several primary features that enhance its functionality and reliability. These include its material composition, typically made from high-quality metals to ensure durability and resistance to corrosion. The reducer also features specific connection types that are designed to fit securely with other components in the system, ensuring a leak-free seal. Additionally, its design specifications are tailored to meet the demanding requirements of commercial truck applications, providing a robust and efficient solution for fluid transfer.

Benefits of Using the 4916566 Tube Fitting Reducer

Incorporating the 4916566 Tube Fitting Reducer into truck systems offers several advantages. Its design contributes to the efficiency of fluid transfer by ensuring a smooth transition between different tube diameters, which helps to maintain consistent flow rates and pressures. The reducer’s durable construction and corrosion-resistant materials enhance its longevity, reducing the need for frequent replacements. Additionally, its compatibility with other components in the system ensures seamless integration, contributing to the overall reliability and performance of the truck.

Installation Considerations

When installing the 4916566 Tube Fitting Reducer, it is important to follow guidelines and best practices to ensure a secure and efficient connection. Necessary tools may include wrenches, torque wrenches, and sealants, depending on the specific application. The installation process typically involves cleaning the connection points, applying sealant if required, and tightening the reducer to the specified torque settings. Safety precautions, such as wearing protective gear and ensuring the system is depressurized, should also be observed to prevent injuries and ensure a successful installation.

Common Issues and Troubleshooting

Typical problems that may arise with the 4916566 Tube Fitting Reducer include leaks, corrosion, and improper fitting. To address these issues, it is important to conduct regular inspections and maintenance. Troubleshooting steps may involve checking for proper torque settings, ensuring that sealants are applied correctly, and verifying that the reducer is compatible with the surrounding components. In cases of corrosion or significant wear, replacement of the reducer may be necessary to restore system integrity.

Maintenance Tips

To ensure the longevity and optimal performance of the 4916566 Tube Fitting Reducer, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the reducer and its connections can help prevent buildup and ensure a secure fit. Additionally, verifying that all connections are tightened to the correct torque settings and that sealants are in good condition will contribute to the reducer’s effectiveness and durability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company offers a wide range of products designed to meet the diverse needs of its customers, ensuring that they can rely on Cummins components for performance and durability in their vehicles.

Compatibility with Cummins Engines

The Tube Fitting Reducer 4916566 is designed to fit seamlessly with various Cummins engine models, providing a reliable connection between different sections of the engine’s fluid pathways.

QSK38 CM2150 MCRS and QSK50 CM2150 MCRS

For the QSK38 CM2150 MCRS and QSK50 CM2150 MCRS engines, the Tube Fitting Reducer 4916566 is engineered to integrate with the engine’s cooling and lubrication systems. These engines benefit from the precise fit and function of this component, ensuring that the fluid flow transitions smoothly, maintaining optimal pressure levels and preventing potential leaks or system failures.

QSK50 CM2350 K108

Similarly, the QSK50 CM2350 K108 engine relies on the Tube Fitting Reducer 4916566 for its intricate fluid management needs. This engine variant requires components that can handle the demands of its operation, and the reducer plays a crucial role in maintaining the integrity of the engine’s fluid pathways, ensuring that the engine operates at peak efficiency.

Role of the 4916566 Tube Fitting Reducer in Engine Systems

The 4916566 Tube Fitting Reducer is a component that facilitates the smooth operation of various engine systems by ensuring proper fluid and air flow between components of different diameters.

In compressor systems, the reducer allows for the transition from larger to smaller tubing, optimizing the flow of compressed air. This is particularly important in high-pressure environments where maintaining consistent pressure is key to efficient compressor performance.

Within air systems, the reducer plays a significant role in regulating the flow of air to different parts of the engine. It ensures that air is distributed evenly, which is vital for maintaining the engine’s performance and longevity.

In plumbing systems, the reducer is used to connect pipes of varying sizes, ensuring that fluid dynamics are maintained. This is important for systems that require precise fluid control, such as cooling systems or lubrication circuits.

For the fan drive system, the reducer helps in managing the airflow to the fan, ensuring that it operates at optimal efficiency. This is particularly important in systems where the fan drive is responsible for cooling critical engine components.

In the broader engine system, the reducer aids in the seamless integration of various subsystems. It ensures that all components, regardless of their size or function, can work together harmoniously.

Lastly, in engine monitoring systems, the reducer assists in the accurate measurement of fluid and air flow. This is essential for maintaining the integrity of the monitoring data, which is used to make informed decisions about engine maintenance and performance enhancements.

Conclusion

The Tube Fitting Reducer 4916566 by Cummins is a critical component in ensuring the efficient and reliable operation of commercial truck systems. Its design and functionality contribute to the smooth transition of fluids between different diameters of tubing, enhancing the overall performance and reliability of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.