4926177

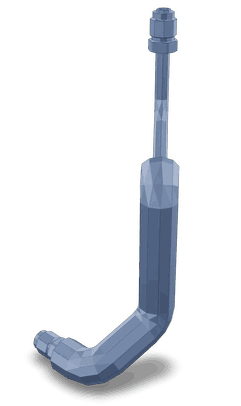

Pressure Sensing Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4926177 Pressure Sensing Tube is a component designed for use in commercial trucks. It serves a specific function within the engine management system, contributing to the overall performance and efficiency of the vehicle. Understanding its purpose and operation is key to maintaining and optimizing truck performance.

Basic Concepts of Pressure Sensing Tubes

Pressure sensing tubes are components used in automotive systems to monitor and transmit pressure data from various parts of the engine to the vehicle’s electronic control unit (ECU). These tubes facilitate the accurate measurement of pressure, which is essential for the ECU to make informed adjustments to engine operations 1. They are integral to ensuring that the engine operates within optimal parameters, enhancing both performance and fuel efficiency.

Purpose of the 4926177 Pressure Sensing Tube

The Cummins 4926177 Pressure Sensing Tube plays a role in the engine management system by accurately conveying pressure readings from the engine to the ECU. This data allows the ECU to adjust fuel injection timing, air-fuel mixture, and other parameters in real-time, ensuring the engine operates efficiently under varying conditions. Its integration within the system is designed to enhance the truck’s performance, reliability, and fuel economy.

Key Features

The Cummins 4926177 Pressure Sensing Tube is constructed from durable materials, ensuring it can withstand the high pressures and temperatures within the engine compartment. Its design includes precise fittings and connections to ensure accurate pressure readings and reliable operation. Unique attributes of this tube may include enhanced resistance to corrosion and wear, contributing to its longevity and performance.

Benefits

The advantages provided by the Cummins 4926177 Pressure Sensing Tube include improved engine performance through precise pressure monitoring, enhanced fuel efficiency by enabling the ECU to make optimal adjustments, and reliable operation under a wide range of conditions. These benefits contribute to the overall efficiency and longevity of the truck’s engine.

Installation and Integration

Installing the Cummins 4926177 Pressure Sensing Tube involves several steps to ensure it functions correctly within the truck’s system. Preparations may include ensuring the engine compartment is clean and free of debris that could interfere with the tube’s operation. Adjustments to existing components may be necessary to accommodate the tube, ensuring it is securely fitted and aligned for accurate pressure readings.

Troubleshooting and Maintenance

Common issues with the Cummins 4926177 Pressure Sensing Tube may include inaccurate pressure readings or physical damage to the tube. Diagnostic procedures involve checking the tube for signs of wear, corrosion, or blockages that could affect its performance. Maintenance tips include regular inspection of the tube and its connections, ensuring they are secure and free from damage, to ensure longevity and optimal performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves commercial, industrial, and automotive markets. In the realm of heavy-duty trucks, Cummins is known for its reliable and high-performance engines and components, including the 4926177 Pressure Sensing Tube, which exemplifies the brand’s dedication to enhancing vehicle efficiency and reliability 2.

Pressure Sensing Tube (Part 4926177) in Cummins Engines

The Pressure Sensing Tube (Part 4926177) is a critical component in Cummins engines, including the ISX CM870. This part plays a vital role in the engine’s operation by providing accurate pressure readings, which are essential for maintaining optimal performance and efficiency.

In the ISX CM870 engine, the Pressure Sensing Tube is integrated into the engine’s fuel system. It is designed to measure the pressure of the fuel as it moves through the system, ensuring that the engine receives the correct fuel pressure for combustion. This is crucial for the engine’s performance, as it directly affects the fuel injection timing and quantity.

The Pressure Sensing Tube is also used in conjunction with other sensors and control systems within the engine. It provides real-time data to the engine control unit (ECU), which uses this information to adjust the fuel injection parameters dynamically. This ensures that the engine operates at peak efficiency under various conditions, from idle to full load.

In the broader context of Cummins engines, the Pressure Sensing Tube is a common component across many models. Its design and function are consistent, ensuring that it provides reliable and accurate pressure readings regardless of the specific engine model. This standardization allows for easier maintenance and repair, as technicians can use their knowledge of the Pressure Sensing Tube across different engine types.

The integration of the Pressure Sensing Tube in Cummins engines highlights the company’s commitment to precision and reliability. This part is a testament to Cummins’ engineering expertise, as it must meet stringent performance standards to ensure the engine’s smooth and efficient operation.

Role of Part 4926177 Pressure Sensing Tube in Engine Systems

The Part 4926177 Pressure Sensing Tube is an integral component in the operation of various engine systems, particularly in the context of recirculation and exhaust management.

Integration with Exhaust Systems

In exhaust systems, the Pressure Sensing Tube is employed to monitor the pressure levels within the exhaust manifold or the exhaust gas recirculation (EGR) system. By accurately sensing the pressure, the engine control unit (ECU) can make precise adjustments to the fuel injection timing and quantity, ensuring optimal combustion efficiency and reduced emissions. This component aids in maintaining the delicate balance required for the EGR system to function correctly, allowing a measured amount of exhaust gas to be recirculated back into the intake manifold. This recirculation helps in lowering the combustion temperature, which in turn reduces the formation of nitrogen oxides (NOx) 3.

Function in Recirculation Systems

Within recirculation systems, the Pressure Sensing Tube plays a significant role in the EGR system by providing real-time data on the pressure differentials. This information is vital for the ECU to determine the appropriate amount of exhaust gas to be reintroduced into the intake air stream. Proper management of this recirculation process is essential for meeting emissions standards and enhancing engine performance. The Pressure Sensing Tube ensures that the EGR valve operates within its designed parameters, preventing issues such as excessive soot buildup or inefficient combustion.

Overall Impact on Engine Performance

The accurate pressure readings provided by the Part 4926177 Pressure Sensing Tube contribute to the overall stability and efficiency of the engine. By enabling the ECU to make informed decisions based on precise pressure data, this component helps in achieving a smoother engine operation, improved fuel economy, and compliance with environmental regulations. Its role in both exhaust and recirculation systems underscores its importance in modern engine management strategies.

Conclusion

The Cummins 4926177 Pressure Sensing Tube is a vital component in the engine management system of commercial trucks. Its role in accurately conveying pressure readings to the ECU allows for dynamic adjustments to engine operations, enhancing performance, reliability, and fuel efficiency. The integration of this part across various Cummins engine models underscores its importance in modern engine management strategies, contributing to the overall efficiency and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.