4926190

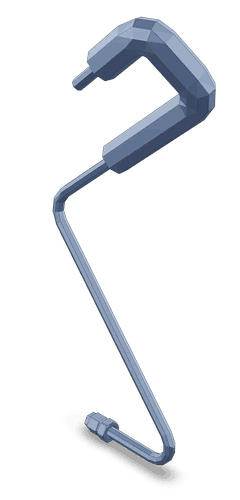

Pressure Sensing Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4926190 Pressure Sensing Tube is a critical component in heavy-duty truck systems, designed to monitor and regulate pressure for optimal performance and efficiency. This part ensures the correct pressure levels necessary for the proper operation of various truck systems.

Basic Concepts of Pressure Sensing Tubes

A Pressure Sensing Tube is a device that measures and monitors pressure within a system. It transmits pressure readings to a sensor or gauge, allowing for real-time monitoring and adjustment of pressure levels. This is vital for the efficient and safe operation of the system 1.

Purpose of the Cummins 4926190 Pressure Sensing Tube

The Cummins 4926190 Pressure Sensing Tube is designed to operate within heavy-duty trucks, ensuring pressure levels are maintained within the desired range. It facilitates the transmission of pressure data from the source to the monitoring device, allowing for precise control and regulation of system pressure 2.

Key Features

The Cummins 4926190 Pressure Sensing Tube features a durable material composition to withstand harsh conditions in heavy-duty truck environments. Its design ensures accurate pressure transmission and resistance to wear and tear. Unique characteristics, such as specific connectors or fittings, facilitate easy installation and integration within the truck’s system.

Benefits of Using the Cummins 4926190 Pressure Sensing Tube

Using the Cummins 4926190 Pressure Sensing Tube offers advantages such as improved system performance, reliability, and efficiency. It ensures accurate pressure monitoring and regulation, contributing to the overall stability and effectiveness of the truck’s systems. This can lead to enhanced operational efficiency, reduced risk of system failures, and prolonged component lifespan 3.

Installation and Integration

Installing the Cummins 4926190 Pressure Sensing Tube involves ensuring the system is clean and free of debris, and verifying that all connections are secure and compatible. Modifications to existing systems may be necessary for seamless integration, allowing for accurate pressure monitoring and regulation.

Troubleshooting Common Issues

Identifying and resolving typical problems associated with the Cummins 4926190 Pressure Sensing Tube, such as leaks, inaccurate readings, or physical damage, is important for maintaining system integrity. Common issues can often be addressed through careful inspection, cleaning, or replacement of damaged components. Regular checks and maintenance can help prevent many of these problems from occurring.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4926190 Pressure Sensing Tube, regular maintenance practices are recommended. These include periodic inspections for signs of wear or damage, cleaning the tube and its connections to remove any buildup, and verifying that all connections remain secure.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s product range includes a variety of components and systems designed to enhance the performance and efficiency of vehicles, including heavy-duty trucks.

Role of Part 4926190 Pressure Sensing Tube in Engine Systems

The Cummins 4926190 Pressure Sensing Tube is an integral component in the operation of both recirculation and exhaust systems within engine configurations.

Exhaust Gas Recirculation (EGR) System

In the EGR system, the Pressure Sensing Tube monitors the pressure differentials between the intake manifold and the exhaust manifold. This data is essential for the EGR valve to function correctly, ensuring that the appropriate amount of exhaust gas is recirculated back into the intake manifold. This recirculation helps in reducing nitrogen oxides (NOx) emissions by lowering the combustion temperature. The Pressure Sensing Tube provides real-time pressure readings, allowing the engine control unit (ECU) to make precise adjustments to the EGR valve, optimizing fuel efficiency and emissions control.

Exhaust System

In the exhaust system, the Pressure Sensing Tube plays a significant role in monitoring backpressure. By gauging the pressure within the exhaust manifold and the exhaust pipe, it assists the ECU in making necessary adjustments to the fuel injection timing and air-fuel ratio. This ensures that the engine operates within optimal parameters, enhancing performance and reducing the risk of engine knock. Additionally, accurate pressure readings help in diagnosing potential issues within the exhaust system, such as blockages or leaks, allowing for timely maintenance and repairs.

Conclusion

The Cummins 4926190 Pressure Sensing Tube is a vital component that enhances the efficiency and reliability of both recirculation and exhaust systems in engine operations. Its role in monitoring and regulating pressure ensures optimal performance and longevity of heavy-duty truck systems.

-

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.