4926194

Pressure Sensing Tube

Cummins®

IN STOCK

8 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4926194 Pressure Sensing Tube is a component designed for use in commercial trucks. It serves a specific function within the truck’s systems, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing truck performance.

Basic Concepts of Pressure Sensing Tubes

Pressure sensing tubes are components used to monitor and regulate pressure within various systems. They work by transmitting pressure readings from one part of the system to another, often to a sensor or gauge. This allows for precise control and adjustment of system operations, ensuring that components function within their optimal pressure ranges 1.

Purpose of the Cummins 4926194 Pressure Sensing Tube

The Cummins 4926194 Pressure Sensing Tube plays a role in the truck’s systems by facilitating accurate pressure readings. It is integrated into the truck’s pressure monitoring and regulation systems, allowing for the efficient operation of components that rely on precise pressure levels. This includes systems related to engine performance, fuel delivery, and emissions control.

Key Features

The Cummins 4926194 Pressure Sensing Tube is characterized by several key features. It is constructed from durable materials to withstand the harsh conditions within a truck’s engine compartment. Its design includes specific elements that ensure accurate pressure transmission, such as a precise bore size and smooth interior surface. Additionally, it may feature unique characteristics like reinforced ends to prevent damage during installation or operation.

Benefits

Using the Cummins 4926194 Pressure Sensing Tube offers several benefits. It contributes to improved system performance by ensuring accurate pressure readings, which are vital for the optimal operation of various truck systems. Its reliable design enhances the overall reliability of the truck, reducing the likelihood of system failures. Furthermore, by facilitating efficient pressure regulation, it plays a part in improving the truck’s fuel efficiency and reducing emissions 2.

Installation Process

Installing the Cummins 4926194 Pressure Sensing Tube requires careful attention to detail. The process involves securing the tube in place within the truck’s system, ensuring it is properly aligned and connected to both the pressure source and the sensor or gauge. Tools required may include wrenches for tightening connections and possibly a pressure tester to verify the installation. Precautions should be taken to avoid damaging the tube or surrounding components during installation.

Troubleshooting Common Issues

Common issues with the Cummins 4926194 Pressure Sensing Tube may include inaccurate pressure readings or leaks. Troubleshooting steps can involve checking the connections for tightness, inspecting the tube for signs of damage or wear, and verifying that the sensor or gauge is functioning correctly. In some cases, reinstallation or replacement of the tube may be necessary to resolve the issue.

Maintenance Tips

Regular maintenance of the Cummins 4926194 Pressure Sensing Tube is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the tube and its connections to remove any debris or buildup, and verifying that all connections remain tight. Following the manufacturer’s recommended maintenance schedule can help prevent issues and ensure the tube continues to function effectively.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. Its product range is designed to meet the demanding requirements of commercial applications, providing reliable and efficient power solutions for a variety of industries.

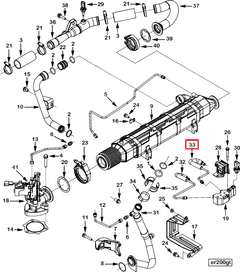

Pressure Sensing Tube (Part 4926194) in Cummins Engines

The Pressure Sensing Tube (Part 4926194) is a critical component in the Cummins ISM CM570/870 engines. This part is integral to the engine’s operation, ensuring accurate monitoring of pressure levels within the system.

In the ISM CM570/870 engines, the Pressure Sensing Tube is designed to interface seamlessly with the engine’s pressure management systems. It provides real-time data to the engine control unit (ECU), which is essential for maintaining optimal performance and efficiency.

The ISM CM570/870 engines are known for their robust design and reliability, and the Pressure Sensing Tube plays a pivotal role in this. By accurately sensing and transmitting pressure data, it helps in preventing potential issues such as over-pressurization, which could lead to engine damage.

This part is engineered to withstand the high-stress conditions within the engine, ensuring durability and longevity. Its precise placement and integration within the engine’s architecture are critical for the overall health and performance of the engine.

Role of Part 4926194 Pressure Sensing Tube in Engine Systems

The Part 4926194 Pressure Sensing Tube is integral to the operation of several engine systems, particularly in the context of recirculation and exhaust management.

In the Exhaust Gas Recirculation (EGR) system, the Pressure Sensing Tube monitors the pressure differentials between the intake manifold and the exhaust manifold. This data is essential for the EGR valve to function correctly, ensuring that the appropriate amount of exhaust gas is recirculated back into the intake manifold. This recirculation helps in reducing nitrogen oxides (NOx) emissions and improving fuel efficiency.

Within the Exhaust system, the Pressure Sensing Tube plays a role in maintaining optimal pressure levels. It provides feedback to the engine control unit (ECU) regarding the backpressure in the exhaust system. This information allows the ECU to make necessary adjustments to the fuel injection timing and air-fuel ratio, ensuring smooth engine operation and minimizing the risk of damage from excessive backpressure.

Additionally, the Pressure Sensing Tube contributes to the overall efficiency of the Turbocharger system by monitoring the pressure before and after the turbine. This allows for precise control of the wastegate, which regulates the amount of exhaust gas bypassing the turbine. Proper management of this pressure ensures that the turbocharger operates within its designed parameters, enhancing both performance and durability.

Conclusion

In summary, the Cummins 4926194 Pressure Sensing Tube is a vital component in the Cummins ISM CM570/870 engines, ensuring that pressure levels are monitored and managed effectively. Its role in various engine systems, including EGR, exhaust, and turbocharger systems, underscores its importance in maintaining optimal engine performance and emissions.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.