This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

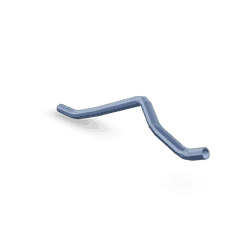

The Cummins 4935827 Breather Tube is a component designed for use in commercial trucks. It serves a specific function within the engine system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and significance is important for maintaining engine health and ensuring optimal performance.

Basic Concepts of Breather Tubes

A breather tube is a component that allows air to enter and exit an engine’s crankcase. Its function is to maintain a balanced pressure within the crankcase, which is important for the proper operation of the engine. The breather tube facilitates the release of gases and moisture that accumulate during engine operation, preventing pressure build-up that could lead to leaks or damage 1.

Purpose of the 4935827 Breather Tube

The Cummins 4935827 Breather Tube plays a role in the engine system by allowing the release of gases and moisture from the crankcase. This helps in maintaining a stable pressure environment, which is important for the engine’s lubrication system and overall performance. By ensuring that the crankcase does not become over-pressurized, the breather tube contributes to the longevity and efficiency of the engine 2.

Key Features

The Cummins 4935827 Breather Tube is characterized by its durable construction and design, which includes materials that resist corrosion and wear. Its design elements are tailored to fit specific engine models, ensuring a secure and effective installation. The tube’s unique characteristics, such as its filtration capabilities, enhance its performance by preventing contaminants from entering the engine system.

Benefits

The use of the Cummins 4935827 Breather Tube offers several advantages. It contributes to improved engine efficiency by maintaining optimal crankcase pressure. Additionally, it reduces the need for frequent maintenance by effectively managing the release of gases and moisture. The tube’s durable construction also enhances the engine’s longevity, providing a reliable solution for commercial truck operators 3.

Installation Process

Installing the Cummins 4935827 Breather Tube requires careful attention to ensure proper fit and function. The process involves securing the tube to the engine’s crankcase and connecting it to the appropriate ventilation system. Tools such as wrenches and sealants may be required, and it is important to follow manufacturer guidelines for correct placement to ensure the tube operates as intended.

Common Issues and Troubleshooting

Issues with the Cummins 4935827 Breather Tube may include blockages or leaks, which can affect engine performance. Troubleshooting these problems involves inspecting the tube for signs of damage or obstruction and addressing any issues promptly. Solutions may include cleaning the tube, replacing damaged sections, or ensuring proper installation to prevent future problems.

Maintenance Tips

Regular maintenance of the Cummins 4935827 Breather Tube is important for its longevity and performance. This includes periodic inspections for signs of wear or damage, cleaning the tube to remove any accumulated contaminants, and ensuring that it remains securely attached to the engine system. Adhering to recommended inspection intervals and maintenance procedures will help maintain the tube’s effectiveness.

Compatibility and Applications

The Cummins 4935827 Breather Tube is designed for use with specific types of trucks and engine models. Its compatibility ensures that it can be effectively integrated into various commercial truck systems, providing a versatile solution for maintaining engine health across different applications.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of engine and component products. The company’s history of innovation and commitment to quality is reflected in its product offerings, including the Cummins 4935827 Breather Tube. Cummins’ reputation for reliability and performance underscores the quality and effectiveness of this component in commercial truck applications.

Breather Tube (Part 4935827) Compatibility with Cummins Engines

The Breather Tube, identified by part number 4935827 and manufactured by Cummins, is a component in the engine’s ventilation system. This part is designed to facilitate the release of air and vapors from the engine’s crankcase, ensuring that the engine operates efficiently and safely.

Compatibility with QSC8.3 CM850 (CM2850)

The Breather Tube (4935827) is specifically engineered to fit seamlessly with the QSC8.3 CM850 (CM2850) engine. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The breather tube’s role in this engine is to maintain proper air pressure within the crankcase, preventing the buildup of harmful gases and moisture that could otherwise lead to engine damage.

Grouping of Engines

While the Breather Tube (4935827) is explicitly designed for the QSC8.3 CM850 (CM2850) engine, it is important to note that similar breather tube components are often used across various Cummins engine models. This is due to the standardized design and function of breather tubes in ensuring engine health and longevity.

Engines within the same series or model group often share similar components, including breather tubes, to maintain consistency in performance and ease of maintenance. Therefore, while the primary focus here is on the QSC8.3 CM850 (CM2850), it is beneficial to understand that the breather tube’s application can extend to other Cummins engines within the same or similar series.

Role of Part 4935827 Breather Tube in Engine Systems

The part 4935827 Breather Tube is a component in maintaining the health and efficiency of engine systems. It is specifically designed to interface with the crankcase and breather system to manage the pressure and ventilation within these components.

Interaction with the Crankcase

The crankcase is a vital part of the engine, housing the crankshaft and connecting rods. During engine operation, the crankcase accumulates gases, moisture, and other byproducts. The Breather Tube facilitates the release of these byproducts, preventing pressure build-up that could lead to leaks or damage. By allowing controlled ventilation, it ensures that the crankcase maintains an optimal environment for the moving parts inside.

Integration with the Breather System

The breather system is responsible for managing the airflow within the engine compartments. The Breather Tube plays a significant role in this system by providing a pathway for gases and moisture to escape from the crankcase. This not only helps in pressure regulation but also contributes to the overall cleanliness of the engine environment. Efficient breather tube functionality ensures that contaminants are expelled, reducing the risk of sludge formation and component wear.

Enhanced Engine Performance

By effectively managing crankcase pressure and ventilation, the Breather Tube contributes to smoother engine operation. It helps in maintaining consistent oil levels by preventing excessive pressure that could force oil past seals and gaskets. This results in better lubrication and cooler operating temperatures, which are important for prolonged engine life and performance.

Maintenance and Reliability

Regular inspection and maintenance of the Breather Tube are important to ensure it remains free from obstructions and damage. A well-maintained Breather Tube ensures that the crankcase and breather system operate efficiently, contributing to the reliability and durability of the engine.

Conclusion

The Cummins 4935827 Breather Tube is a vital component in the maintenance and efficiency of commercial truck engines. Its role in managing crankcase pressure and ventilation is crucial for engine health and performance. Regular maintenance and proper installation are key to ensuring the longevity and reliability of this Cummins part.

-

Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Robert Bosch GmbH, Springer Vieweg, 2007

↩ -

Diesel and Gasoline Engines, Richard Viskup, IntechOpen, 2020

↩ -

Brakes Brake Control and Driver Assistance Systems Function Regulation and Components, Konrad Reif Ed, Springer, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.