This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

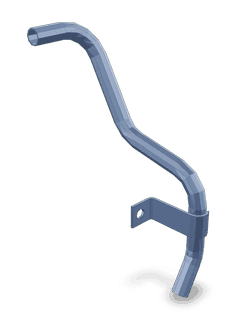

The Cummins 4941113 Breather Tube is a component designed for use in commercial trucks. It serves a specific function within the engine system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining optimal truck performance.

Basic Concepts of Breather Tubes

Breather tubes are components found in engine systems that allow for the release of pressure and the removal of moisture from the engine crankcase. They play a role in maintaining engine health by ensuring that the crankcase does not become over-pressurized and that contaminants are expelled from the system. This helps in preserving the integrity of engine components and ensuring smooth operation 1.

Purpose of the Cummins 4941113 Breather Tube

The Cummins 4941113 Breather Tube is designed to facilitate pressure equalization and moisture removal within the engine crankcase of a truck. By allowing air to enter and exit the crankcase as needed, it helps maintain a stable environment inside the engine. This process aids in preventing the buildup of pressure that could lead to leaks or damage and ensures that moisture, which can lead to corrosion and other issues, is effectively managed.

Key Features

The Cummins 4941113 Breather Tube is constructed with specific design elements and materials to enhance its performance and durability. Its design incorporates features that allow for efficient air flow and moisture expulsion. The materials used are selected for their ability to withstand the harsh conditions within an engine environment, ensuring long-term reliability and performance.

Benefits

Incorporating the Cummins 4941113 Breather Tube into a truck’s engine system can lead to several benefits. These include improved engine performance due to better pressure management and moisture control, extended lifespan of engine components by reducing the risk of corrosion and damage, and enhanced overall reliability of the truck, contributing to safer and more efficient operations.

Installation and Integration

Proper installation of the Cummins 4941113 Breather Tube is crucial for its effective operation within a truck’s engine system. This process involves ensuring that the tube is correctly positioned and securely attached to prevent leaks and ensure optimal functionality. Considerations should be given to the specific requirements of the truck’s engine system to ensure compatibility and proper integration.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important for ensuring the Cummins 4941113 Breather Tube continues to operate effectively. Common issues may include blockages or damage to the tube, which can affect its performance. Maintenance practices should include periodic inspections and cleaning to remove any contaminants that may have accumulated, ensuring the breather tube remains in optimal condition.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck components industry. With a history of innovation and quality, Cummins is recognized for its commitment to producing reliable and high-performance parts. The company’s reputation is built on a foundation of expertise and a dedication to meeting the needs of its customers with products that enhance the efficiency and reliability of commercial vehicles 2.

Cummins Engine Breather Tube 4941113 Compatibility

The Cummins Breather Tube part number 4941113 is designed to fit a variety of Cummins engines, ensuring proper ventilation and maintaining the integrity of the engine’s crankcase system. This part is crucial for managing the pressure within the engine’s crankcase, preventing oil leaks, and avoiding the ingestion of contaminants.

Engine Compatibility

-

B3.3: The Breather Tube 4941113 is engineered to integrate seamlessly with the B3.3 engine, providing essential ventilation and maintaining the necessary pressure balance within the crankcase.

-

QSB3.3 CM2150: This part is also compatible with the QSB3.3 CM2150 engine. Its design ensures that the crankcase pressure is regulated, preventing oil leaks and contamination, which are critical for the engine’s longevity and performance.

The Breather Tube 4941113 is a critical component for these engines, ensuring that the crankcase ventilation system operates efficiently. Its compatibility with both the B3.3 and QSB3.3 CM2150 engines underscores its versatility and importance in maintaining engine health.

Role of Part 4941113 Breather Tube in Engine Systems

The part 4941113 Breather Tube is an essential component in managing the internal pressures within engine systems. It is specifically designed to interface with the crankcase and the breather system to ensure optimal engine performance and longevity.

Integration with the Crankcase

The breather tube connects to the crankcase, which houses the crankshaft and connecting rods. As the engine operates, the crankcase accumulates gases and vapors from the combustion process. The breather tube facilitates the release of these byproducts, preventing a buildup of pressure that could lead to oil leaks or engine damage.

Function within the Breather System

In conjunction with the breather system, the 4941113 Breather Tube plays a significant role in maintaining a balanced pressure environment. The breather system is responsible for venting excess gases and moisture from the crankcase. The breather tube acts as a conduit, allowing these substances to escape while preventing external contaminants from entering the crankcase. This ensures that the oil remains clean and effective, contributing to the overall efficiency and reliability of the engine.

Operational Synergy

During engine operation, the breather tube works in harmony with other components such as the PCV (Positive Crankcase Ventilation) valve. The PCV valve regulates the flow of gases from the crankcase back into the intake manifold, where they are re-burned. The breather tube supports this process by providing an alternative route for gases to escape, especially when the PCV valve is unable to handle the volume. This synergy helps in reducing emissions and enhancing fuel efficiency.

Maintenance and Performance

Regular maintenance of the breather tube is vital for sustained engine performance. Over time, the tube may become clogged with debris or oil sludge, impeding its function. Ensuring the breather tube remains clear and operational is key to preventing issues such as oil contamination and pressure buildup within the crankcase.

Conclusion

The Cummins 4941113 Breather Tube is a pivotal component in the engine’s breather and crankcase systems, facilitating the release of gases and maintaining a stable pressure environment, which is essential for the engine’s durability and efficiency. Proper installation, regular maintenance, and understanding its role within the engine system are crucial for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.