4942633

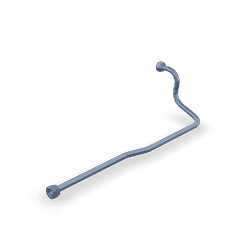

Compressor Water Outlet Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Compressor Water Outlet Tube, part number 4942633, is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its heavy-duty truck components. This tube is integral to the cooling system of heavy-duty truck engines, ensuring that the engine operates within optimal temperature ranges.

Basic Concepts and Functionality

The Compressor Water Outlet Tube functions within the engine’s cooling system. Its role is to direct coolant flow from the compressor to other parts of the engine, aiding in the regulation of engine temperature. By maintaining a consistent coolant flow, it helps prevent overheating and ensures that the engine operates efficiently 1.

Purpose and Role in Truck Operation

In the context of heavy-duty truck engines, the Compressor Water Outlet Tube serves a specific purpose. It is designed to enhance engine performance and longevity by ensuring that the engine remains cool under various operating conditions. This component contributes to the overall efficiency and reliability of the engine 2.

Key Features

The Compressor Water Outlet Tube is characterized by several key features. It is constructed from durable materials to withstand the high pressures and temperatures within the engine. Its design includes precise engineering to ensure a secure fit and efficient coolant flow. Additionally, it may incorporate unique characteristics that further enhance its performance and durability 3.

Benefits

Using the Compressor Water Outlet Tube offers several benefits. It contributes to improved engine efficiency by ensuring optimal coolant flow. This reduces the risk of overheating and enhances the overall reliability of the engine. The tube’s design and material composition also contribute to its durability and performance under demanding conditions 4.

Installation and Compatibility

Proper installation of the Compressor Water Outlet Tube is crucial for its effective operation. It is compatible with various engine models, and specific installation guidelines should be followed to ensure a secure and efficient fit. These guidelines may include torque specifications and alignment requirements to maintain the integrity of the cooling system.

Maintenance and Troubleshooting

Maintaining the Compressor Water Outlet Tube is important for ensuring its optimal performance. Regular inspections for signs of wear or damage can help identify potential issues early. Common problems may include leaks or blockages, which can be addressed through cleaning or replacement as necessary. Recommended maintenance practices include periodic checks and following the manufacturer’s guidelines for care.

Performance Impact

The Compressor Water Outlet Tube plays a role in engine performance by contributing to efficient coolant flow. This can impact fuel efficiency, power output, and overall engine reliability. By maintaining optimal engine temperature, it helps ensure that the engine operates within its designed parameters, potentially leading to improved performance and longevity.

Design and Engineering

The engineering and design of the Compressor Water Outlet Tube reflect careful consideration of the demands placed on it within the engine system. Its design may incorporate innovative features or technologies to enhance performance, durability, and efficiency. These design elements contribute to the tube’s ability to withstand the pressures and temperatures of heavy-duty truck engines.

Cummins Overview

Cummins Inc. is a prominent manufacturer in the automotive industry, with a history of producing high-quality components for heavy-duty trucks. The company’s product range includes a variety of engine components and systems, known for their reliability and performance. Cummins has established a reputation for excellence in the realm of heavy-duty truck components, backed by a commitment to innovation and quality.

Cummins Engine Compatibility with Part 4942633

The Compressor Water Outlet Tube, part number 4942633, manufactured by Cummins, is a critical component in the cooling system of several Cummins engine models. This part is designed to manage the flow of coolant from the compressor, ensuring efficient heat dissipation and maintaining optimal engine performance.

ISL G Series

The ISL G series engines, particularly the ISL G CM2180, benefit significantly from the precise engineering of the 4942633 part. This component is integral to the cooling system, facilitating the transfer of coolant from the compressor to the radiator. Its design ensures that the engine operates within safe temperature limits, enhancing longevity and reliability.

CM2180 Series

In the CM2180 series, the 4942633 part is equally essential. It is meticulously engineered to fit seamlessly within the cooling system architecture of these engines. The part’s compatibility with the CM2180 series underscores Cummins’ commitment to providing high-quality, durable components that meet the rigorous demands of heavy-duty applications.

Group Compatibility

The 4942633 part is not limited to individual engine models but is also compatible with a broader group of Cummins engines. This versatility allows for easier maintenance and repair across different engine types, providing a cost-effective solution for operators and technicians. The design of the part ensures it fits snugly and functions optimally within the cooling systems of these engines, contributing to their overall efficiency and performance.

Role of Part 4942633 Compressor Water Outlet Tube in Engine Systems

The Compressor Water Outlet Tube is an essential component in the efficient operation of engine systems, particularly in the management and regulation of the compressor coolant. This tube is integral to the plumbing arrangement that ensures the proper flow of coolant from the compressor.

In the context of the compressor coolant system, the Compressor Water Outlet Tube facilitates the exit of coolant from the compressor after it has absorbed heat. This process is vital for maintaining optimal operating temperatures within the compressor, thereby enhancing its efficiency and longevity.

The tube’s placement within the plumbing arrangement is meticulously designed to interface seamlessly with other components of the coolant system. It connects to the compressor’s outlet port, allowing the heated coolant to be directed away from the compressor and towards the cooling system or heat exchanger. This ensures that the coolant can be effectively cooled before being recirculated back into the system.

Moreover, the efficient design of the Compressor Water Outlet Tube contributes to the overall reliability of the compressor coolant system. By ensuring a consistent and unimpeded flow of coolant, it helps prevent issues such as overheating, which can lead to compressor failure.

Conclusion

In summary, the Compressor Water Outlet Tube plays a significant role in the effective management of the compressor coolant, ensuring that the engine system operates within safe temperature ranges and maintains high performance standards. Its design, compatibility with various Cummins engine models, and contribution to engine efficiency and reliability make it a critical component in the maintenance and operation of heavy-duty truck engines.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.