4946157

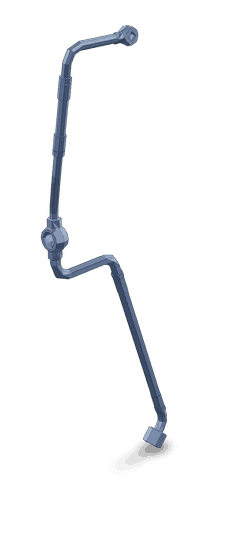

Tur Coolant Supply Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

In the realm of commercial truck engines, the coolant supply tube plays a pivotal role in maintaining optimal engine temperature and performance. Among the various components, the Tur Coolant Supply Tube (Part #4946157) by Cummins stands out for its critical function in the cooling system. Understanding and maintaining this component is essential for ensuring the longevity and efficiency of the engine 1.

Basic Concepts Related To The Tur Coolant Supply Tube

A coolant supply tube is a vital part of the engine’s cooling system, responsible for transporting coolant from the radiator to the engine block. In commercial truck engines, efficient coolant circulation is crucial for dissipating heat generated during operation. The Tur Coolant Supply Tube specifically facilitates this process, ensuring that coolant reaches the engine’s critical components, thereby maintaining stable operating temperatures 2.

How The Tur Coolant Supply Tube Works

The Tur Coolant Supply Tube is meticulously designed using high-quality materials to withstand the demanding conditions within a commercial truck engine. Typically made from durable rubber or reinforced plastic, the tube is engineered to handle high pressures and temperatures. The coolant flow through the tube begins at the radiator, where it is cooled by air passing through the fins. From there, it travels through the Tur Coolant Supply Tube into the engine block, where it absorbs heat. Maintaining proper pressure and flow within the tube is crucial to prevent overheating and ensure efficient engine operation 3.

Purpose Of The Tur Coolant Supply Tube (Part #4946157)

The primary role of the Tur Coolant Supply Tube in engine operation is to deliver coolant to the engine block and other critical components. This ensures that the engine maintains an optimal operating temperature, which is essential for efficiency and longevity. A malfunctioning Tur Coolant Supply Tube can lead to inadequate coolant flow, resulting in engine overheating, reduced performance, and potential damage to engine components.

Cummins: A Leader In Engine Manufacturing

Cummins is renowned in the industry for its commitment to quality and innovation in engine components. The company’s reputation for manufacturing reliable and high-performance parts makes Cummins-manufactured components, like the Tur Coolant Supply Tube, a preferred choice for commercial truck operators. Cummins’ dedication to excellence ensures that their parts contribute significantly to the efficiency and reliability of commercial truck engines.

Troubleshooting The Tur Coolant Supply Tube

Common issues with the Tur Coolant Supply Tube include leaks, blockages, and degradation due to age or exposure to extreme conditions. Symptoms of a faulty tube may include engine overheating, coolant leaks, or fluctuating temperature gauge readings. To troubleshoot, begin by inspecting the tube for visible signs of damage or wear. If a leak is detected, the tube should be replaced immediately to prevent further engine damage. Regular inspections and maintenance are crucial for identifying potential issues before they lead to significant problems.

Maintenance Tips For The Tur Coolant Supply Tube

To ensure the longevity and efficiency of the Tur Coolant Supply Tube, regular maintenance is essential. This includes periodic inspections for signs of wear, cracks, or leaks. Using genuine Cummins parts for replacements is highly recommended to maintain the integrity of the cooling system. Additionally, following the manufacturer’s guidelines for coolant type and change intervals can help extend the lifespan of the tube and the overall cooling system.

Expert Insights And Best Practices

Industry experts emphasize the significance of the Tur Coolant Supply Tube in maintaining engine performance. Best practices for ensuring the longevity and efficiency of this component include regular inspections, prompt replacement of worn or damaged tubes, and using high-quality coolant. Real-world examples demonstrate that proper maintenance of the Tur Coolant Supply Tube can significantly impact engine performance, leading to improved efficiency, reduced downtime, and extended engine life.

Role of Part 4946157 Tur Coolant Supply Tube in Engine Systems

The 4946157 Tur Coolant Supply Tube is an essential component in the efficient operation of engine systems, particularly in relation to the turbocharger and overall plumbing setup.

Integration with Turbocharger

In turbocharged engine systems, the turbocharger operates under extreme conditions, necessitating effective cooling to maintain performance and longevity. The 4946157 Tur Coolant Supply Tube facilitates the delivery of coolant to the turbocharger, ensuring that it remains within optimal temperature ranges. This tube connects to the turbocharger’s coolant passages, allowing for consistent coolant flow that absorbs excess heat generated during operation.

Contribution to Plumbing System

The Tur Coolant Supply Tube is a vital element in the engine’s plumbing system. It interfaces with the main coolant passages, branching off to supply the turbocharger with the necessary coolant. This integration ensures that the coolant circulation is uninterrupted, maintaining a stable thermal environment across the engine components. The tube’s precise fitting and secure connections are paramount to prevent leaks and ensure efficient coolant distribution.

Enhanced System Performance

By effectively managing the temperature of the turbocharger, the 4946157 Tur Coolant Supply Tube contributes to the overall performance and reliability of the engine system. Proper coolant supply reduces the risk of thermal stress on the turbocharger, leading to consistent power output and prolonged component life. Additionally, the tube’s role in the plumbing system ensures that all engine components receive adequate cooling, promoting a balanced and efficient operation.

Conclusion

Understanding and maintaining the Tur Coolant Supply Tube (Part #4946157) by Cummins is crucial for the optimal performance and longevity of commercial truck engines. By prioritizing the care of this critical component, engineers, mechanics, and fleet operators can ensure efficient engine operation and minimize the risk of overheating and related issues. Continued education and adherence to best practices will further enhance the reliability and performance of commercial truck engines.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.