4965362

Pressure Sensing Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4965362 Pressure Sensing Tube is a component designed for use in commercial trucks. It serves a specific function within the engine management system, contributing to the overall performance and efficiency of the vehicle. This part is integral to monitoring and regulating pressure, ensuring that the engine operates within optimal parameters.

Basic Concepts of Pressure Sensing Tubes

Pressure sensing tubes are components used in various systems to monitor and regulate pressure. They function by transmitting pressure readings from one part of a system to another, typically to a sensor or control unit. These tubes are vital for maintaining the correct pressure levels, which is essential for the efficient operation of engines and other mechanical systems. They help in detecting any anomalies in pressure, allowing for timely adjustments or interventions 1.

Purpose of the Cummins 4965362 Pressure Sensing Tube

This Cummins part plays a role in the engine management system of commercial trucks by accurately transmitting pressure readings. This information is used by the engine control unit to make necessary adjustments to ensure optimal engine performance. Its integration into the system allows for precise monitoring and regulation of pressure, contributing to the overall efficiency and reliability of the engine 2.

Key Features

The Cummins 4965362 Pressure Sensing Tube is characterized by its robust design and the quality materials used in its construction. These features enhance its performance and reliability. The tube is designed to withstand the harsh conditions typically encountered in commercial truck engines, ensuring durability and consistent performance. Its design also facilitates easy integration into the engine management system.

Benefits

Using the Cummins 4965362 Pressure Sensing Tube offers several benefits. It contributes to improved engine performance by ensuring that pressure levels are maintained within optimal ranges. This can lead to enhanced fuel efficiency, as the engine operates more efficiently under the right conditions. Additionally, the durability of the tube ensures long-term reliability, reducing the need for frequent replacements or repairs.

Installation and Integration

Installing the Cummins 4965362 Pressure Sensing Tube into a commercial truck’s engine management system involves several steps. It requires careful alignment and connection to ensure accurate pressure readings. The process may require specific tools or equipment, and it’s important to follow manufacturer guidelines to ensure proper integration. This step is crucial for the tube to function effectively within the system.

Troubleshooting and Maintenance

Common issues with the Cummins 4965362 Pressure Sensing Tube may include inaccurate pressure readings or physical damage to the tube. Troubleshooting these issues involves checking the connections, ensuring the tube is properly aligned, and inspecting for any signs of wear or damage. Regular maintenance, such as cleaning and inspecting the tube, can help prevent issues and ensure optimal performance. Following manufacturer recommendations for maintenance can extend the lifespan of the tube and maintain its efficiency.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its high-quality engine and powertrain technologies. With a history of innovation and a broad range of product offerings, Cummins has built a reputation for reliability and performance. The company’s commitment to quality and customer satisfaction is evident in its products, including the Cummins 4965362 Pressure Sensing Tube 3.

Role of Part 4965362 Pressure Sensing Tube in Engine Systems

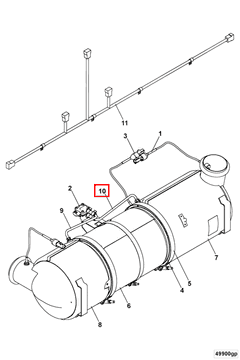

This part is an integral component in the monitoring and regulation of various engine systems, particularly in conjunction with aftertreatment devices. This tube facilitates the accurate measurement of pressure within the system, which is essential for the proper functioning of several interconnected components.

In the context of an aftertreatment device, the Pressure Sensing Tube is responsible for relaying pressure data from the exhaust gas recirculation (EGR) system to the engine control unit (ECU). This data allows the ECU to make real-time adjustments to the EGR valve, ensuring optimal performance and efficiency.

Additionally, the Pressure Sensing Tube plays a significant role in the diesel particulate filter (DPF) system. By providing continuous pressure readings, it enables the ECU to monitor the condition of the DPF and initiate regeneration processes when necessary. This helps maintain the filter’s effectiveness in reducing harmful emissions.

Furthermore, the Pressure Sensing Tube is vital in the selective catalytic reduction (SCR) system. It measures the pressure differential across the SCR catalyst, allowing the ECU to adjust the injection of urea (DEF) into the exhaust stream. This ensures that the SCR system operates within its designed parameters, effectively converting nitrogen oxides (NOx) into harmless nitrogen and water.

Conclusion

In summary, the 4965362 Pressure Sensing Tube is a key component in ensuring the seamless operation of aftertreatment devices by providing essential pressure data to the ECU, thereby enhancing overall engine performance and emissions control.

-

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.