4965374

Pressure Sensing Tube

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4965374 Pressure Sensing Tube is a component designed for use in commercial trucks. It serves a specific function within the truck’s system, contributing to the overall efficiency and performance of the vehicle. Understanding its purpose and significance is important for maintaining and optimizing truck operations.

Basic Concepts of Pressure Sensing Tubes

A pressure sensing tube is a component that facilitates the measurement and monitoring of pressure within a system. In the context of a truck, it plays a role in conveying pressure readings from various points in the system to a sensor or gauge. This information is vital for the proper functioning of the truck, as it allows for the monitoring of critical parameters such as fuel pressure, air pressure in the braking system, or hydraulic pressure in various subsystems. Pressure sensing technology relies on the principle that changes in pressure can be detected and measured, providing valuable data for system management and diagnostics 1.

Role of the 4965374 Pressure Sensing Tube in Truck Operation

This Cummins part is integral to the operation of a truck by enabling accurate pressure readings within the system. It interacts with sensors and other components to ensure that pressure levels are maintained within specified ranges. This is particularly important for systems such as the fuel injection system, where precise pressure control is necessary for optimal engine performance. The tube allows for the transmission of pressure data, which is then used by the truck’s electronic control unit (ECU) to make adjustments and ensure efficient operation 2.

Key Features

This part is characterized by several key features that enhance its performance. These include its material composition, which is designed to withstand the pressures and temperatures encountered within a truck’s system. The tube’s design elements, such as its length and diameter, are tailored to fit specific applications and ensure accurate pressure readings. Additionally, any unique characteristics, such as reinforced sections or specialized coatings, contribute to its durability and reliability in demanding environments.

Benefits of Using the 4965374 Pressure Sensing Tube

Incorporating this part into a truck’s system offers several advantages. It contributes to improved system efficiency by enabling precise pressure monitoring and control. This can lead to better fuel economy and reduced wear on components. The tube’s reliability ensures consistent performance, minimizing the risk of system failures. Furthermore, by facilitating accurate diagnostics, it can help in identifying issues early, potentially leading to cost savings for fleet operators through reduced downtime and maintenance costs 3.

Installation and Integration

Proper installation and integration of this Cummins part are important for ensuring its effective operation within a truck’s system. This involves following manufacturer guidelines for placement, securing the tube in position, and connecting it to the appropriate sensors and components. Preparations may include cleaning the installation area, checking for any obstructions, and ensuring that all connections are secure and leak-free. Careful integration is important to maintain the integrity of the pressure sensing system and ensure accurate readings.

Troubleshooting and Maintenance

To maintain optimal performance and longevity of this part, regular troubleshooting and maintenance are recommended. This includes checking for signs of wear or damage, ensuring connections remain secure, and verifying that the tube is free from obstructions. Troubleshooting common issues may involve testing pressure readings for accuracy, inspecting the tube for leaks, and addressing any discrepancies promptly. Adhering to recommended maintenance practices can help prevent issues and ensure the continued reliability of the pressure sensing system.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products including engines, filtration systems, and aftermarket parts. With a history of innovation and quality, Cummins has built a reputation for delivering reliable and high-performance solutions for the transportation sector. The company’s commitment to excellence is reflected in its product offerings, which are designed to meet the demanding requirements of commercial truck operations.

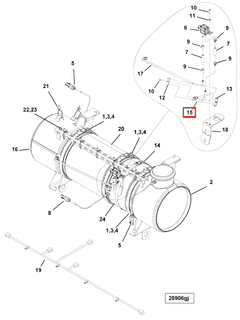

Role of Part 4965374 Pressure Sensing Tube in Aftertreatment Systems

The 4965374 Pressure Sensing Tube is integral to the operation of aftertreatment devices and systems within modern engine configurations. This component is designed to monitor and relay pressure data from various points within the aftertreatment system to the engine control unit (ECU).

In the context of an aftertreatment device, such as a Diesel Particulate Filter (DPF) or Selective Catalytic Reduction (SCR) system, the Pressure Sensing Tube provides real-time pressure readings. These readings are essential for the ECU to make adjustments to the engine’s operation, ensuring optimal performance and compliance with emissions regulations.

For the aftertreatment system as a whole, which may include multiple components like the DPF, SCR, and associated sensors and actuators, the Pressure Sensing Tube plays a supportive role. It helps in diagnosing potential issues by providing continuous feedback on the system’s pressure dynamics. This allows for proactive maintenance and ensures the longevity and efficiency of the aftertreatment system.

The data collected by the Pressure Sensing Tube aids in the fine-tuning of the aftertreatment processes, such as the regeneration of the DPF or the injection timing of the urea solution in the SCR system. This results in improved overall system performance and reduced environmental impact.

Conclusion

The Cummins 4965374 Pressure Sensing Tube is a vital component in the operation of commercial trucks, particularly within aftertreatment systems. Its role in providing accurate pressure readings and facilitating system diagnostics contributes to improved efficiency, performance, and compliance with emissions regulations. Proper installation, maintenance, and understanding of its features and benefits are essential for maximizing the effectiveness of this part in truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.