This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4967702 Breather Tube is a component designed to facilitate the ventilation of the engine crankcase in commercial trucks. Its role is to allow the release of gases and vapors that accumulate within the engine, thereby maintaining a balanced pressure environment and contributing to the overall health and efficiency of the engine 1.

Basic Concepts of Breather Tubes

A breather tube is a vital component in a truck’s engine system, designed to manage the pressure within the engine crankcase. As the engine operates, it produces gases and vapors that need to be expelled to prevent pressure build-up, which could lead to oil leaks and other issues. The breather tube facilitates this process by providing a pathway for these gases to escape, thus maintaining optimal engine conditions 2.

Purpose of the 4967702 Breather Tube

The 4967702 Breather Tube plays a role in the engine’s ventilation system by allowing the release of gases and vapors from the crankcase. This function helps in maintaining a stable pressure environment within the engine, which is important for the efficient operation of the engine and the prevention of oil contamination 3.

Key Features

The design and construction of the 4967702 Breather Tube incorporate several features that enhance its performance and durability. These include a robust material composition that resists corrosion and wear, a precise fit to ensure a secure connection within the engine system, and a design that facilitates easy installation and maintenance.

Benefits of Using the 4967702 Breather Tube

Utilizing the 4967702 Breather Tube offers several advantages, including improved engine performance through effective ventilation, enhanced longevity of the engine components due to reduced pressure and contamination, and increased reliability of the engine system as a whole.

Installation Process

Installing the 4967702 Breather Tube involves several steps to ensure proper integration into the engine system. This process includes preparing the engine area, aligning the breather tube with its designated port, securing it in place, and verifying the connection for leaks or improper fit. Specific tools or additional components may be required to complete the installation.

Maintenance Tips

Regular maintenance of the 4967702 Breather Tube is important to ensure its optimal functioning. This includes periodic inspection for signs of wear or damage, cleaning the tube to remove any accumulated debris or contaminants, and replacing it if necessary to maintain engine efficiency and reliability.

Troubleshooting Common Issues

Common problems associated with breather tubes can include blockages, leaks, or damage to the tube itself. Addressing these issues may involve cleaning the tube, repairing or replacing damaged sections, or ensuring proper installation to prevent future problems.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and power generation markets, among others. The company is known for its commitment to customer satisfaction and technological advancement in the commercial truck industry.

Cummins Breather Tube 4967702 Compatibility

The Cummins Breather Tube part number 4967702 is designed to fit seamlessly with several Cummins engine models, ensuring optimal performance and reliability. This breather tube is integral to the engine’s ventilation system, allowing for the release of gases and preventing pressure build-up within the engine’s crankcase.

QSK19 Engines

The QSK19 engine series, known for its robust design and efficiency, incorporates the 4967702 breather tube. This part is crucial in maintaining the engine’s air filtration system, ensuring that the crankcase remains at a safe pressure level. The QSK19 engines are typically used in heavy-duty applications, and the breather tube’s role in these engines cannot be overstated.

CM2350 Engines

Similarly, the CM2350 engine series benefits from the 4967702 breather tube. This engine model is designed for high-performance applications, and the breather tube ensures that the engine operates smoothly by managing the pressure within the crankcase. The CM2350 engines are often found in marine and industrial applications, where reliability and efficiency are paramount.

K105 Engines

The K105 engine series, another robust offering from Cummins, also utilizes the 4967702 breather tube. This part is essential for the K105 engines, which are designed for heavy-duty use. The breather tube helps in maintaining the engine’s air filtration system, ensuring that the crankcase remains at a safe pressure level, which is critical for the longevity and performance of the engine.

By integrating the 4967702 breather tube into these engine models, Cummins ensures that the engines operate efficiently and reliably, providing the necessary ventilation to prevent pressure build-up and maintain optimal performance.

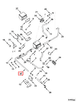

Role of Part 4967702 Breather Tube in Engine Systems

The part 4967702 breather tube is an essential component in the crankcase breather arrangement of an engine system. Its primary function is to manage the pressure within the crankcase by allowing gases to escape while preventing external contaminants from entering.

In the crankcase breather arrangement, the breather tube is connected to the crankcase, which houses the crankshaft and connecting rods. As the engine operates, the pistons move up and down, creating pressure fluctuations within the crankcase. The breather tube facilitates the release of these gases, maintaining a stable pressure environment.

Additionally, the breather tube is often linked to the air intake system, allowing the expelled gases to be re-circulated back into the combustion process. This not only helps in pressure regulation but also contributes to reducing emissions by ensuring that any unburned hydrocarbons are re-introduced into the engine for combustion.

The effective functioning of the breather tube is dependent on its integration with other components such as the PCV (Positive Crankcase Ventilation) valve. The PCV valve regulates the flow of gases through the breather tube, ensuring that the crankcase does not become over-pressurized.

Conclusion

In summary, the 4967702 breather tube plays a significant role in maintaining the efficiency and longevity of the engine by ensuring proper pressure management within the crankcase and facilitating the re-circulation of gases for improved emission control.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.