This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

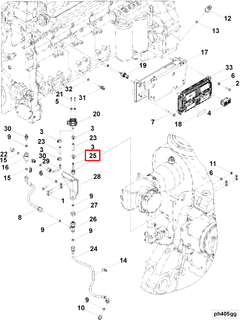

The 4968826 Pressure Sensing Tube Assembly is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This assembly is integral to the operation of commercial trucks, contributing to the efficient and safe functioning of the vehicle’s systems.

Basic Concepts of Pressure Sensing Tube Assembly

Pressure sensing tube assemblies are designed to monitor and regulate pressure within a truck’s system. They work by transmitting pressure readings from various points in the system to a control unit, which then uses this data to make adjustments as necessary. This ensures that the system operates within safe and efficient parameters, preventing issues such as over-pressurization or under-pressurization that could lead to component failure or reduced performance 1.

Purpose of the Pressure Sensing Tube Assembly

This Cummins part plays a role in the operation of a truck by providing accurate pressure readings from critical points within the system. It is integrated with other components to ensure that the engine and other systems receive the correct pressure levels for optimal performance. This assembly helps in maintaining the balance and efficiency of the truck’s operations by ensuring that pressure levels are consistently monitored and adjusted.

Key Features

The 4968826 is characterized by its robust design and the use of high-quality materials that ensure durability and reliability. The assembly is engineered to withstand the harsh conditions typically encountered in commercial truck operations. Its design includes precise fittings and connections that ensure accurate pressure readings and minimal risk of leaks or failures. Additionally, the assembly may feature unique characteristics such as corrosion-resistant coatings or enhanced sealing mechanisms to further improve its performance and longevity.

Benefits

The implementation of the Pressure Sensing Tube Assembly offers several benefits. It contributes to improved system efficiency by ensuring that pressure levels are maintained within optimal ranges. This can lead to enhanced performance and reliability of the truck’s systems. Moreover, by providing accurate pressure readings, the assembly plays a role in enhancing safety, as it helps prevent issues that could arise from incorrect pressure levels. Fleet operators may also experience potential cost savings due to reduced maintenance needs and improved system longevity.

Installation Process

Installing this part requires careful attention to detail to ensure proper function and integration within the truck’s system. The process involves several steps, including preparing the installation site, connecting the assembly to the appropriate points within the system, and securing all connections to prevent leaks. Tools required may include wrenches, torque wrenches, and possibly a pressure testing kit to verify the integrity of the installation. Following the manufacturer’s guidelines is crucial to ensure a successful installation.

Maintenance and Troubleshooting

Regular maintenance of the Pressure Sensing Tube Assembly is important to ensure its continued reliable operation. This includes periodic inspections to check for signs of wear, corrosion, or leaks. Common issues to watch for may include inaccurate pressure readings, which could indicate a problem with the assembly or its connections. Troubleshooting tips may involve checking all connections for tightness, inspecting for signs of damage or corrosion, and ensuring that the assembly is properly aligned and installed. Addressing issues promptly can help prevent more significant problems down the line.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its high-quality products and innovative solutions. With a rich history and a strong reputation for reliability and performance, Cummins offers a wide range of products designed to meet the demanding needs of commercial truck operators. The company’s commitment to quality and customer satisfaction is evident in its products, including the 4968826 Pressure Sensing Tube Assembly.

Pressure Sensing Tube Assembly (Part 4968826) Compatibility with Cummins Engines

The Pressure Sensing Tube Assembly, part number 4968826, manufactured by Cummins, is a critical component in several engine models. This part is integral to the engine’s operation, ensuring accurate pressure readings and maintaining optimal performance.

GTA855 CM558 (CM2358) G101

The GTA855 CM558 (CM2358) G101 engine is one of the models that utilize the Pressure Sensing Tube Assembly. This engine is known for its robust design and high performance, often used in heavy-duty applications. The pressure sensing tube assembly in this engine ensures that the pressure readings are accurate, which is crucial for the engine’s efficiency and longevity.

KTA19GC CM558

Similarly, the KTA19GC CM558 engine also incorporates the Pressure Sensing Tube Assembly. This engine is designed for demanding industrial applications, where precise pressure monitoring is essential. The part 4968826 plays a vital role in maintaining the engine’s operational integrity by providing reliable pressure data.

Grouping of Engines

Both the GTA855 CM558 (CM2358) G101 and KTA19GC CM558 engines fall under the category of high-performance, heavy-duty engines. The Pressure Sensing Tube Assembly is a common component in these engines, highlighting its importance in ensuring accurate pressure readings and maintaining the engine’s efficiency. The use of this part across these models underscores its critical role in the engine’s overall performance and reliability.

Role of Part 4968826 Pressure Sensing Tube Assembly in Engine Systems

This part is an integral component in the operation of engine systems, particularly in its interaction with the module and engine control units.

This assembly is responsible for accurately transmitting pressure readings from various points within the engine to the engine control module (ECM). The ECM relies on these precise pressure readings to make real-time adjustments to the engine’s performance parameters.

The assembly interfaces directly with the engine’s pressure sensors, which are strategically placed to monitor critical areas such as the intake manifold, turbocharger, and fuel system.

By providing consistent and reliable pressure data, the 4968826 assembly ensures that the ECM can effectively manage fuel injection timing, air-fuel ratio, and other vital functions.

This seamless communication between the pressure sensing tube assembly and the ECM is essential for maintaining optimal engine efficiency, performance, and emissions control.

Conclusion

In summary, the 4968826 Pressure Sensing Tube Assembly plays a significant role in enhancing the overall functionality and reliability of modern engine systems. Its robust design, precise pressure readings, and integration with engine control modules contribute to the efficient and safe operation of commercial trucks. Regular maintenance and proper installation are crucial to ensure the continued performance and longevity of this critical component.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.